Electroluminescence

Electroluminescence can be exploited in light sources. Such sources typically emit from a large area, which makes them suitable for backlights of LCD displays. The excitation of the phosphor is usually achieved by application of high-intensity electric field, usually with suitable frequency. Current electroluminescent light sources tend to degrade with use, resulting in their relatively short operation lifetimes.

ZnS:Cu was the first formulation successfully displaying electroluminescence, tested at 1936 by Georges Destriau in Madame Marie Curie laboratories in Paris.

Powder or AC electroluminescence is found in a variety of backlight and night light applications. Several groups offer branded EL offerings (e.g. IndiGlo used in some Timex watches) or "Lighttape", another trade name of an electroluminescent material, used in electroluminescent light strips. The Apollo space program is often credited with being the first significant use of EL for backlights and lighting.[21]

White LEDs

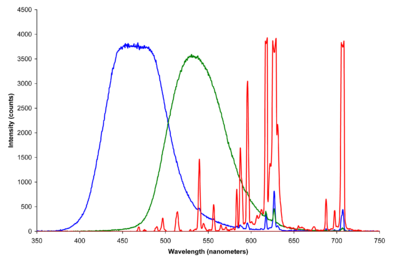

White light-emitting diodes are usually blue InGaN LEDs with a coating of a suitable material. Cerium(III)-doped YAG (YAG:Ce3+, or Y3Al5O12:Ce3+) is often used; it absorbs the light from the blue LED and emits in a broad range from greenish to reddish, with most of its output in yellow. This yellow emission combined with the remaining blue emission gives the "white" light, which can be adjusted to color temperature as warm (yellowish) or cold (bluish) white. The pale yellow emission of the Ce3+:YAG can be tuned by substituting the cerium with other rare-earth elements such as terbium and gadolinium and can even be further adjusted by substituting some or all of the aluminium in the YAG with gallium. However, this process is not one of phosphorescence. The yellow light is produced by a process known as scintillation, the complete absence of an afterglow being one of the characteristics of the process.

Some rare-earth-doped Sialons are photoluminescent and can serve as phosphors. Europium(II)-doped β-SiAlON absorbs in ultraviolet and visible light spectrum and emits intense broadband visible emission. Its luminance and color does not change significantly with temperature, due to the temperature-stable crystal structure. It has a great potential as a green down-conversion phosphor for white LEDs; a yellow variant also exists (α-SiAlON[22]). For white LEDs, a blue LED is used with a yellow phosphor, or with a green and yellow SiAlON phosphor and a red CaAlSiN3-based (CASN) phosphor.[23][24][25]

White LEDs can also be made by coating near-ultraviolet-emitting LEDs with a mixture of high-efficiency europium-based red- and blue-emitting phosphors plus green-emitting copper- and aluminium-doped zinc sulfide (ZnS:Cu,Al). This is a method analogous to the way fluorescent lamps work.

Some newer white LEDs use a yellow and blue emitter in series, to approximate white; this technology is used in some Motorola phones such as the Blackberry as well as LED lighting and the original-version stacked emitters by using GaN on SiC on InGaP but was later found to fracture at higher drive currents.

Many white LEDs used in general lighting systems can be used for data transfer, as, for example, in systems that modulate the LED to act as a beacon.[26]

It is also common for white LEDs to use phosphors other than Ce:YAG, or to use two or three phosphors to achieve a higher CRI, often at the cost of efficiency. Examples of additional phosphors are R9, which produces a saturated red, nitrides which produce red, and aluminates such as lutetium aluminum garnet that produce green. Silicate phosphors are brighter but fade more quickly, and are used in LCD LED backlights in mobile devices. LED phosphors can be placed directly over the die or made into a dome and placed above the LED: this approach is known as a remote phosphor.[27] Some colored LEDs, instead of using a colored LED, use a blue LED with a colored phosphor because such an arrangement is more efficient than a colored LED. Oxynitride phosphors can also be used in LEDs. The precursors used to make the phosphors may degrade when exposed to air.[28]

Cathode-ray tubes

Cathode-ray tubes produce signal-generated light patterns in a (typically) round or rectangular format. Bulky CRTs were used in the black-and-white household television (TV) sets that became popular in the 1950s, as well as first-generation, tube-based color TVs, and most earlier computer monitors. CRTs have also been widely used in scientific and engineering instrumentation, such as oscilloscopes, usually with a single phosphor color, typically green. Phosphors for such applications may have long afterglow, for increased image persistence.

The phosphors can be deposited as either thin film, or as discrete particles, a powder bound to the surface. Thin films have better lifetime and better resolution, but provide less bright and less efficient image than powder ones. This is caused by multiple internal reflections in the thin film, scattering the emitted light.

White (in black-and-white): The mix of zinc cadmium sulfide and zinc sulfide silver, the ZnS:Ag + (Zn,Cd)S:Ag is the white P4 phosphor used in black and white television CRTs. Mixes of yellow and blue phosphors are usual. Mixes of red, green and blue, or a single white phosphor, can also be encountered.

Red: Yttrium oxide-sulfide activated with europium is used as the red phosphor in color CRTs. The development of color TV took a long time due to the search for a red phosphor. The first red emitting rare-earth phosphor, YVO4:Eu3+, was introduced by Levine and Palilla as a primary color in television in 1964.[29] In single crystal form, it was used as an excellent polarizer and laser material.[30]

Yellow: When mixed with cadmium sulfide, the resulting zinc cadmium sulfide (Zn,Cd)S:Ag, provides strong yellow light.

Green: Combination of zinc sulfide with copper, the P31 phosphor or ZnS:Cu, provides green light peaking at 531 nm, with long glow.

Blue: Combination of zinc sulfide with few ppm of silver, the ZnS:Ag, when excited by electrons, provides strong blue glow with maximum at 450 nm, with short afterglow with 200 nanosecond duration. It is known as the P22B phosphor. This material, zinc sulfide silver, is still one of the most efficient phosphors in cathode-ray tubes. It is used as a blue phosphor in color CRTs.

The phosphors are usually poor electrical conductors. This may lead to deposition of residual charge on the screen, effectively decreasing the energy of the impacting electrons due to electrostatic repulsion (an effect known as "sticking"). To eliminate this, a thin layer of aluminium (about 100 nm) is deposited over the phosphors, usually by vacuum evaporation, and connected to the conductive layer inside the tube. This layer also reflects the phosphor light to the desired direction, and protects the phosphor from ion bombardment resulting from an imperfect vacuum.

To reduce the image degradation by reflection of ambient light, contrast

can be increased by several methods. In addition to black masking of

unused areas of screen, the phosphor particles in color screens are

coated with pigments of matching color. For example, the red phosphors

are coated with ferric oxide (replacing earlier Cd(S,Se) due to cadmium toxicity), blue phosphors can be coated with marine blue (CoO·nAl

2O

3) or ultramarine (Na

8Al

6Si

6O

24S

2). Green phosphors based on ZnS:Cu do not have to be coated due to their own yellowish color.[7]

Black-and-white television CRTs

The black-and-white television screens require an emission color close to white. Usually, a combination of phosphors is employed.

The most common combination is ZnS:Ag + (Zn,Cd)S:Cu,Al (blue + yellow). Other ones are ZnS:Ag + (Zn,Cd)S:Ag (blue + yellow), and ZnS:Ag + ZnS:Cu,Al + Y2O2S:Eu3+ (blue + green + red – does not contain cadmium and has poor efficiency). The color tone can be adjusted by the ratios of the components.

As the compositions contain discrete grains of different phosphors, they produce image that may not be entirely smooth. A single, white-emitting phosphor, (Zn,Cd)S:Ag,Au,Al overcomes this obstacle. Due to its low efficiency, it is used only on very small screens.

The screens are typically covered with phosphor using sedimentation coating, where particles suspended in a solution are let to settle on the surface.[31]

Reduced-palette color CRTs

For displaying of a limited palette of colors, there are a few options.

In beam penetration tubes, different color phosphors are layered and separated with dielectric material. The acceleration voltage is used to determine the energy of the electrons; lower-energy ones are absorbed in the top layer of the phosphor, while some of the higher-energy ones shoot through and are absorbed in the lower layer. So either the first color or a mixture of the first and second color is shown. With a display with red outer layer and green inner layer, the manipulation of accelerating voltage can produce a continuum of colors from red through orange and yellow to green.

Another method is using a mixture of two phosphors with different characteristics. The brightness of one is linearly dependent on electron flux, while the other one's brightness saturates at higher fluxes—the phosphor does not emit any more light regardless of how many more electrons impact it. At low electron flux, both phosphors emit together; at higher fluxes, the luminous contribution of the nonsaturating phosphor prevails, changing the combined color.[31]

Such displays can have high resolution, due to absence of two-dimensional structuring of RGB CRT phosphors. Their color palette is, however, very limited. They were used e.g. in some older military radar displays.

Color television CRTs

This section is missing information about time period of each phosphor composition. (October 2020) |

The phosphors in color CRTs need higher contrast and resolution than the black-and-white ones. The energy density of the electron beam is about 100 times greater than in black-and-white CRTs; the electron spot is focused to about 0.2 mm diameter instead of about 0.6 mm diameter of the black-and-white CRTs. Effects related to electron irradiation degradation are therefore more pronounced.

Color CRTs require three different phosphors, emitting in red, green and blue, patterned on the screen. Three separate electron guns are used for color production (except for displays that use beam-index tube technology, which is rare). The red phosphor has always been a problem, being the dimmest of the three necessitating the brighter green and blue electron beam currents be adjusted down to make them equal the red phosphor's lower brightness. This made early color TVs only usable indoors as bright light made it impossible to see the dim picture, while portable black-and-white TVs viewable in outdoor sunlight were already common.

The composition of the phosphors changed over time, as better phosphors were developed and as environmental concerns led to lowering the content of cadmium and later abandoning it entirely. The (Zn,Cd)S:Ag,Cl was replaced with (Zn,Cd)S:Cu,Al with lower cadmium/zinc ratio, and then with cadmium-free ZnS:Cu,Al.

The blue phosphor stayed generally unchanged, a silver-doped zinc sulfide. The green phosphor initially used manganese-doped zinc silicate, then evolved through silver-activated cadmium-zinc sulfide, to lower-cadmium copper-aluminium activated formula, and then to cadmium-free version of the same. The red phosphor saw the most changes; it was originally manganese-activated zinc phosphate, then a silver-activated cadmium-zinc sulfide, then the europium(III) activated phosphors appeared; first in an yttrium vanadate matrix, then in yttrium oxide and currently in yttrium oxysulfide. The evolution of the phosphors was therefore (ordered by B-G-R):

- ZnS:Ag – Zn2SiO4:Mn – Zn3(PO4)2:Mn

- ZnS:Ag – (Zn,Cd)S:Ag – (Zn,Cd)S:Ag

- ZnS:Ag – (Zn,Cd)S:Ag – YVO4:Eu3+ (1964–?)

- ZnS:Ag – (Zn,Cd)S:Cu,Al – Y2O2S:Eu3+ or Y2O3:Eu3+

- ZnS:Ag – ZnS:Cu,Al or ZnS:Au,Cu,Al – Y2O2S:Eu3+[31]

Projection televisions

For projection televisions, where the beam power density can be two orders of magnitude higher than in conventional CRTs, some different phosphors have to be used.

For blue color, ZnS:Ag,Cl is employed. However, it saturates. (La,Gd)OBr:Ce,Tb3+ can be used as an alternative that is more linear at high energy densities.

For green, a terbium-activated Gd2O2Tb3+; its color purity and brightness at low excitation densities is worse than the zinc sulfide alternative, but it behaves linear at high excitation energy densities, while zinc sulfide saturates. However, it also saturates, so Y3Al5O12:Tb3+ or Y2SiO5:Tb3+ can be substituted. LaOBr:Tb3+ is bright but water-sensitive, degradation-prone, and the plate-like morphology of its crystals hampers its use; these problems are solved now, so it is gaining use due to its higher linearity.

Y2O2S:Eu3+ is used for red emission.[31]

https://en.wikipedia.org/wiki/Phosphor

No comments:

Post a Comment