Selective leaching, also called dealloying, demetalification, parting and selective corrosion, is a corrosion type in some solid solutionalloys, when in suitable conditions a component of the alloys is preferentially leached from the material. The less noble metal is removed from the alloy by a microscopic-scale galvanic corrosion mechanism. The most susceptible alloys are the ones containing metals with high distance between each other in the galvanic series, e.g. copper and zinc in brass. The elements most typically undergoing selective removal are zinc, aluminium, iron, cobalt, chromium, and others.

Graphitic corrosion[edit]

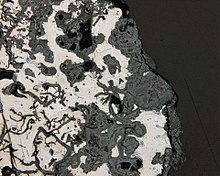

Graphitic corrosion is selective leaching of iron, from grey cast iron, where iron is removed and graphite grains remain intact. Affected surfaces develop a layer of graphite, rust, and metallurgical impurities that may inhibit further leaching. The effect can be substantially reduced by alloying the cast iron with nickel.[1]

Leaching of other elements[edit]

Dealuminification is a corresponding process for aluminum alloys. Similar effects for different metals are decarburization(removal of carbon from the surface of alloy), decobaltification, denickelification, etc.

Countermeasures[edit]

Countermeasures involve using alloys not susceptible to grain boundary depletion, using a suitable heat treatment, altering the environment (e.g. lowering oxygen content), and/or use cathodic protection.

Uses[edit]

Selective leaching can be used to produce powdered materials with extremely high surface area, such as Raney nickel and other heterogeneous catalysts.[2] Selective leaching can be the pre-final stage of depletion gilding.

https://en.wikipedia.org/wiki/Selective_leaching

No comments:

Post a Comment