In physics and engineering, a resultant forceis the single force and associated torqueobtained by combining a system of forces and torques acting on a rigid body via vector addition. The defining feature of a resultant force, or resultant force-torque, is that it has the same effect on the rigid body as the original system of forces.[1] Calculating and visualizing the resultant force on a body is done through computational analysis, or (in the case of sufficiently simple systems) a free body diagram.

The point of application of the resultant force determines its associated torque. The term resultant force should be understood to refer to both the forces and torques acting on a rigid body, which is why some use the term ' resultant force-torque.

https://en.wikipedia.org/wiki/Resultant_force

https://en.wikipedia.org/wiki/Bending_moment

https://en.wikipedia.org/wiki/Cantilever

https://en.wikipedia.org/wiki/Hogging_and_sagging

In solid mechanics, a point along a beam under a lateral load is known as a point of contraflexure if the bending moment about the point equals zero.[1] In a bending moment diagram, it is the point at which the bending moment curve intersects with the zero line (i.e. where the bending moment reverses direction along the beam). Knowing the place of the contraflexure is especially useful when designing reinforced concrete or structural steel beams and also for designing bridges.

Flexural reinforcement may be reduced at this point. However, to omit reinforcement at the point of contraflexure entirely is inadvisable as the actual location is unlikely to realistically be defined with confidence. Additionally, an adequate quantity of reinforcement should extend beyond the point of contraflexure to develop bond strength and to facilitate shear force transfer.

See also[edit]

- Deformation

- Engineering mechanics

- Flexural rigidity

- Flexural stress

- Fluid mechanics

- Inflection point

- Strength of materials

https://en.wikipedia.org/wiki/Contraflexure

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation.

The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. In some materials, such as aluminium, there is a gradual onset of non-linear behavior, making the precise yield point difficult to determine. In such a case, the offset yield point (or proof stress) is taken as the stress at which 0.2% plastic deformation occurs. Yielding is a gradual failure mode which is normally not catastrophic, unlike ultimate failure.

In solid mechanics, the yield point can be specified in terms of the three-dimensional principal stresses () with a yield surface or a yield criterion. A variety of yield criteria have been developed for different materials.

https://en.wikipedia.org/wiki/Yield_(engineering)

The second moment of area, or second area moment, or quadratic moment of area and also known as the area moment of inertia, is a geometrical property of an area which reflects how its points are distributed with regard to an arbitrary axis. The second moment of area is typically denoted with either an (for an axis that lies in the plane) or with a (for an axis perpendicular to the plane). In both cases, it is calculated with a multiple integral over the object in question. Its dimension is L (length) to the fourth power. Its unit of dimension, when working with the International System of Units, is meters to the fourth power, m4, or inches to the fourth power, in4, when working in the Imperial System of Units.

In structural engineering, the second moment of area of a beam is an important property used in the calculation of the beam's deflection and the calculation of stress caused by a moment applied to the beam. In order to maximize the second moment of area, a large fraction of the cross-sectional area of an I-beam is located at the maximum possible distance from the centroid of the I-beam's cross-section. The planar second moment of area provides insight into a beam's resistance to bending due to an applied moment, force, or distributed load perpendicular to its neutral axis, as a function of its shape. The polar second moment of area provides insight into a beam's resistance to torsional deflection, due to an applied moment parallel to its cross-section, as a function of its shape.

Different disciplines use the term moment of inertia (MOI) to refer to different moments. It may refer to either of the planar second moments of area (often or , with respect to some reference plane), or the polar second moment of area (, where r is the distance to some reference axis). In each case the integral is over all the infinitesimal elements of area, dA, in some two-dimensional cross-section. In physics, moment of inertia is strictly the second moment of masswith respect to distance from an axis: , where r is the distance to some potential rotation axis, and the integral is over all the infinitesimal elements of mass, dm, in a three-dimensional space occupied by an object Q. The MOI, in this sense, is the analog of mass for rotational problems. In engineering (especially mechanical and civil), moment of inertia commonly refers to the second moment of the area.[1]

https://en.wikipedia.org/wiki/Second_moment_of_area

In continuum mechanics, stress is a physical quantity that expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solidvertical bar is supporting an overhead weight, each particle in the bar pushes on the particles immediately below it. When a liquid is in a closed container under pressure, each particle gets pushed against by all the surrounding particles. The container walls and the pressure-inducing surface (such as a piston) push against them in (Newtonian) reaction. These macroscopic forces are actually the net result of a very large number of intermolecular forces and collisions between the particles in those molecules. Stress is frequently represented by a lowercase Greek letter sigma (σ).

Strain inside a material may arise by various mechanisms, such as stress as applied by external forces to the bulk material (like gravity) or to its surface (like contact forces, external pressure, or friction). Any strain (deformation) of a solid material generates an internal elastic stress, analogous to the reaction force of a spring, that tends to restore the material to its original non-deformed state. In liquids and gases, only deformations that change the volume generate persistent elastic stress. However, if the deformation changes gradually with time, even in fluids there will usually be some viscous stress, opposing that change. Elastic and viscous stresses are usually combined under the name mechanical stress.

Significant stress may exist even when deformation is negligible or non-existent (a common assumption when modeling the flow of water). Stress may exist in the absence of external forces; such built-in stress is important, for example, in prestressed concrete and tempered glass. Stress may also be imposed on a material without the application of net forces, for example by changes in temperature or chemical composition, or by external electromagnetic fields (as in piezoelectric and magnetostrictive materials).

The relation between mechanical stress, deformation, and the rate of change of deformation can be quite complicated, although a linear approximation may be adequate in practice if the quantities are sufficiently small. Stress that exceeds certain strength limits of the material will result in permanent deformation (such as plastic flow, fracture, cavitation) or even change its crystal structure and chemical composition.

In some branches of engineering, the term stress is occasionally used in a looser sense as a synonym of "internal force". For example, in the analysis of trusses, it may refer to the total traction or compression force acting on a beam, rather than the force divided by the area of its cross-section.

https://en.wikipedia.org/wiki/Stress_(mechanics)

In physics, tension is described as the pulling force transmitted axially by the means of a string, a cable, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as the action-reaction pair of forces acting at each end of said elements. Tension could be the opposite of compression.

At the atomic level, when atoms or molecules are pulled apart from each other and gain potential energy with a restoring force still existing, the restoring force might create what is also called tension. Each end of a string or rod under such tension could pull on the object it is attached to, in order to restore the string/rod to its relaxed length.

In physics, tension, as a transmitted force, as an action-reaction pair of forces, or as a restoring force, may be a force and has the units of force measured in newtons (or sometimes pounds-force). The ends of a string or other object transmitting tension will exert forces on the objects to which the string or rod is connected, in the direction of the string at the point of attachment. These forces due to tension are also called "passive forces". There are two basic possibilities for systems of objects held by strings:[1] either acceleration is zero and the system is therefore in equilibrium, or there is acceleration, and therefore a net force is present in the system.

https://en.wikipedia.org/wiki/Tension_(physics)

In solid mechanics, shearing forces are unaligned forces pushing one part of a body in one specific direction, and another part of the body in the opposite direction. When the forces are colinear (aligned into each other), they are called compression forces. An example is a deck of cards being pushed one way on the top, and the other at the bottom, causing the cards to slide. Another example is when windblows at the side of a peaked roof of a house - the side walls experience a force at their top pushing in the direction of the wind, and their bottom in the opposite direction, from the ground or foundation. William A. Nash defines shear force in terms of planes: "If a plane is passed through a body, a force acting along this plane is called a shear force or shearing force."[1]

https://en.wikipedia.org/wiki/Shear_force

In mechanics, a couple is a system of forces with a resultant (a.k.a.net or sum) moment but no resultant force.[1]

A better term is force couple or pure moment. Its effect is to create rotation without translation, or more generally without any acceleration of the centre of mass. In rigid body mechanics, force couples are free vectors, meaning their effects on a body are independent of the point of application.

The resultant moment of a couple is called a torque. This is not to be confused with the term torque as it is used in physics, where it is merely a synonym of moment.[2]Instead, torque is a special case of moment. Torque has special properties that moment does not have, in particular the property of being independent of reference point, as described below.

https://en.wikipedia.org/wiki/Couple_(mechanics)

In mechanics, the normal force is the component of a contact force that is perpendicular to the surface that an object contacts, as in Figure 1.[1] In this instance normalis used in the geometric sense and means perpendicular, as opposed to the common language use of normal meaning "ordinary" or "expected". A person standing still on a platform is acted upon by gravity, which would pull them down towards the Earth's coreunless there were a countervailing force from the resistance of the platform's molecules, a force which is named the "normal force".

The normal force is one type of ground reaction force. If the person stands on a slope and does not sink into the ground or slide downhill, the total ground reaction force can be divided into two components: a normal force perpendicular to the ground and a frictional force parallel to the ground. In another common situation, if an object hits a surface with some speed, and the surface can withstand the impact, the normal force provides for a rapid deceleration, which will depend on the flexibility of the surface and the object.

https://en.wikipedia.org/wiki/Normal_force

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other.[2] There are several types of friction:

- Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into static friction ("stiction") between non-moving surfaces, and kinetic friction between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as asperities (see Figure 1).

- Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other.[3][4]

- Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces.[5][6][7]

- Skin friction is a component of drag, the force resisting the motion of a fluid across the surface of a body.

- Internal friction is the force resisting motion between the elements making up a solid material while it undergoes deformation.[4]

When surfaces in contact move relative to each other, the friction between the two surfaces converts kinetic energy into thermal energy (that is, it converts work to heat). This property can have dramatic consequences, as illustrated by the use of friction created by rubbing pieces of wood together to start a fire. Kinetic energy is converted to thermal energy whenever motion with friction occurs, for example when a viscous fluid is stirred. Another important consequence of many types of friction can be wear, which may lead to performance degradation or damage to components. Friction is a component of the science of tribology.

Friction is desirable and important in supplying traction to facilitate motion on land. Most land vehicles rely on friction for acceleration, deceleration and changing direction. Sudden reductions in traction can cause loss of control and accidents.

Friction is not itself a fundamental force. Dry friction arises from a combination of inter-surface adhesion, surface roughness, surface deformation, and surface contamination. The complexity of these interactions makes the calculation of friction from first principlesimpractical and necessitates the use of empirical methods for analysis and the development of theory.

Friction is a non-conservative force – work done against friction is path dependent. In the presence of friction, some kinetic energy is always transformed to thermal energy, so mechanical energy is not conserved.

https://en.wikipedia.org/wiki/Friction

In physics, and in particular in biomechanics, the ground reaction force (GRF) is the force exerted by the ground on a body in contact with it.[1] For example, a person standing motionless on the ground exerts a contact force on it (equal to the person's weight) and at the same time an equal and opposite ground reaction force is exerted by the ground on the person.

In the above example, the ground reaction force coincides with the notion of a normal force. However, in a more general case, the GRF will also have a component parallel to the ground, for example when the person is walking – a motion that requires the exchange of horizontal (frictional) forces with the ground.[2]

The use of the word reaction derives from Newton's third law, which essentially states that if a force, called action, acts upon a body, then an equal and opposite force, called reaction, must act upon another body. The force exerted by the ground is conventionally referred to as the reaction, although, since the distinction between action and reaction is completely arbitrary, the expression ground action would be, in principle, equally acceptable.

The component of the GRF parallel to the surface is the frictional force. When slippage occurs the ratio of the magnitude of the frictional force to the normal force yields the coefficient of static friction.[3]

GRF is often observed to evaluate force production in various groups within the community. One of these groups studied often are athletes to help evaluate a subject's ability to exert force and power. This can help create baseline parameters when creating strength and conditioning regimens from a rehabilitation and coaching standpoint. Plyometric jumps such as a drop-jump is an activity often used to build greater power and force which can lead to overall better ability on the playing field. When landing from a safe height in a bilateral comparisons on GRF in relation to landing with the dominant foot first followed by the non-dominant limb, literature has shown there were no significances in bilateral components with landing with the dominant foot first faster than the non-dominant foot on the GRF of the drop-jump or landing on vertical GRF output.[4]

https://en.wikipedia.org/wiki/Ground_reaction_force

Pages in category "Mathematics of rigidity"

The following 14 pages are in this category, out of 14 total. This list may not reflect recent changes (learn more).

https://en.wikipedia.org/wiki/Category:Mathematics_of_rigidity

https://en.wikipedia.org/wiki/Category:Mechanics

https://en.wikipedia.org/wiki/Category:Dynamical_systems

In classical mechanics, a physical system is termed a monogenic system if the force acting on the system can be modelled in a particular, especially convenient mathematical form. The systems that are typically studied in physics are monogenic. The term was introduced by Cornelius Lanczos in his book The Variational Principles of Mechanics (1970).[1][2]

In Lagrangian mechanics, the property of being monogenic is a necessary condition for certain different formulations to be mathematically equivalent. If a physical system is both a holonomic system and a monogenic system, then it is possible to derive Lagrange's equations from d'Alembert's principle; it is also possible to derive Lagrange's equations from Hamilton's principle.[3]

https://en.wikipedia.org/wiki/Monogenic_system

Stall torque is the torque produced by a mechanical device whose output rotational speed is zero. It may also mean the torque load that causes the output rotational speed of a device to become zero, i.e., to cause stalling. Electric motors, steam engines and hydrodynamic transmissions are all capable of developing torque when stalled.

https://en.wikipedia.org/wiki/Stall_torque

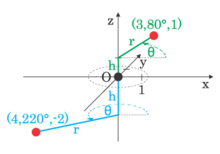

In statistical mechanics, the radial distribution function, (or pair correlation function) in a system of particles (atoms, molecules, colloids, etc.), describes how density varies as a function of distance from a reference particle.

If a given particle is taken to be at the origin O, and if is the average number density of particles, then the local time-averaged density at a distance from O is . This simplified definition holds for a homogeneous and isotropic system. A more general case will be considered below.

https://en.wikipedia.org/wiki/Radial_distribution_function

The following is a list of centroids of various two-dimensional and three-dimensional objects. The centroid of an object in -dimensional space is the intersection of all hyperplanes that divide into two parts of equal moment about the hyperplane. Informally, it is the "average" of all points of . For an object of uniform composition, the centroid of a body is also its center of mass. In the case of two-dimensional objects shown below, the hyperplanes are simply lines.

https://en.wikipedia.org/wiki/List_of_centroids

Chain drive is a way of transmitting mechanical power from one place to another. It is often used to convey power to the wheels of a vehicle, particularly bicycles and motorcycles. It is also used in a wide variety of machines besides vehicles.

https://en.wikipedia.org/wiki/Chain_drive

Cyclic stress is the distribution of forces (aka stresses) that change over time in a repetitive fashion. As an example, consider one of the large wheels used to drive an aerial lift such as a ski lift. The wire cable wrapped around the wheel exerts a downward force on the wheel and the drive shaft supporting the wheel. Although the shaft, wheel, and cable move, the force remains nearly vertical relative to the ground. Thus a point on the surface of the drive shaft will undergo tension when it is pointing towards the ground and compression when it is pointing to the sky.

https://en.wikipedia.org/wiki/Cyclic_stress

In physics, Carroll's paradox arises when considering the motion of a falling rigid rod that is specially constrained. Considered one way, the angular momentum stays constant; considered in a different way, it changes. It is named after Michael M. Carroll who first published it in 1984.

https://en.wikipedia.org/wiki/Carroll%27s_paradox

Non-smooth mechanics is a modeling approach in mechanics which does not require the time evolutions of the positions and of the velocities to be smooth functions anymore. Due to possible impacts, the velocities of the mechanical system are even allowed to undergo jumps at certain time instants in order to fulfill the kinematical restrictions. Consider for example a rigid model of a ball which falls on the ground. Just before the impact between ball and ground, the ball has non-vanishing pre-impact velocity. At the impact time instant, the velocity must jump to a post-impact velocity which is at least zero, or else penetration would occur. Non-smooth mechanical models are often used in contact dynamics.

https://en.wikipedia.org/wiki/Non-smooth_mechanics

The center of percussion is the point on an extended massive object attached to a pivot where a perpendicular impact will produce no reactive shock at the pivot. Translational and rotational motions cancel at the pivot when an impulsive blow is struck at the center of percussion. The center of percussion is often discussed in the context of a bat, racquet, door, sword or other extended object held at one end.

The same point is called the center of oscillation for the object suspended from the pivot as a pendulum, meaning that a simple pendulum with all its mass concentrated at that point will have the same period of oscillation as the compound pendulum.

In sports, the center of percussion of a bat or racquet is related to the so-called "sweet spot", but the latter is also related to vibrational bending of the object.

https://en.wikipedia.org/wiki/Center_of_percussion

https://en.wikipedia.org/wiki/Category:Oscillation

Category:Dimensionless numbers of mechanics

Category for dimensionless numbers in mechanics.

Pages in category "Dimensionless numbers of mechanics"

The following 3 pages are in this category, out of 3 total. This list may not reflect recent changes (learn more).

https://en.wikipedia.org/wiki/Category:Dimensionless_numbers_of_mechanics

A banked turn (or banking turn) is a turn or change of direction in which the vehicle banks or inclines, usually towards the inside of the turn. For a road or railroad this is usually due to the roadbed having a transverse down-slope towards the inside of the curve. The bank angle is the angle at which the vehicle is inclined about its longitudinal axis with respect to the horizontal.

https://en.wikipedia.org/wiki/Banked_turn

In mechanics, a cylinder stress is a stress distribution with rotational symmetry; that is, which remains unchanged if the stressed object is rotated about some fixed axis.

Cylinder stress patterns include:

- circumferential stress, or hoop stress, a normal stress in the tangential (azimuth) direction.

- axial stress, a normal stress parallel to the axis of cylindrical symmetry.

- radial stress, a normal stress in directions coplanar with but perpendicular to the symmetry axis.

These three principal stresses- hoop, longitudinal, and radial can be calculated analytically using a mutually perpendicular tri-axial stress system.[1]

https://en.wikipedia.org/wiki/Cylinder_stress

Pressure drop is defined as the difference in total pressure between two points of a fluid carrying network. A pressure drop occurs when frictional forces, caused by the resistance to flow, act on a fluid as it flows through the tube. The main determinants of resistance to fluid flow are fluid velocity through the pipe and fluid viscosity. Pressure drop increases proportionally to the frictional shear forces within the piping network. A piping network containing a high relative roughness rating as well as many pipe fittings and joints, tube convergence, divergence, turns, surface roughness, and other physical properties will affect the pressure drop. High flow velocities and/or high fluid viscosities result in a larger pressure drop across a section of pipe or a valve or elbow. Low velocity will result in lower or no pressure drop. The fluid may also be biphasic as in pneumatic conveying with a gas and a solid, in this case, the friction of the solid must also be taken into consideration for calculating the pressure drop.[1]

See also[edit]

- Darcy–Weisbach equation (To calculate pressure drop in a channel)

- Hagen–Poiseuille equation

https://en.wikipedia.org/wiki/Pressure_drop

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that does not transfer power to a shaft, but is used to guide the cable or exert a force, the supporting shell is called a block, and the pulley may be called a sheave.

A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain.

https://en.wikipedia.org/wiki/Pulley

A simple machine is a mechanical device that changes the direction or magnitude of a force.[2] In general, they can be defined as the simplest mechanisms that use mechanical advantage (also called leverage) to multiply force.[3] Usually the term refers to the six classical simple machines that were defined by Renaissance scientists:[4][5][6]

A simple machine uses a single applied force to do work against a single load force. Ignoring friction losses, the work done on the load is equal to the work done by the applied force. The machine can increase the amount of the output force, at the cost of a proportional decrease in the distance moved by the load. The ratio of the output to the applied force is called the mechanical advantage.

Simple machines can be regarded as the elementary "building blocks" of which all more complicated machines (sometimes called "compound machines"[7][8]) are composed.[3][9] For example, wheels, levers, and pulleys are all used in the mechanism of a bicycle.[10][11] The mechanical advantage of a compound machine is just the product of the mechanical advantages of the simple machines of which it is composed.

Although they continue to be of great importance in mechanics and applied science, modern mechanics has moved beyond the view of the simple machines as the ultimate building blocks of which all machines are composed, which arose in the Renaissance as a neoclassical amplification of ancient Greek texts. The great variety and sophistication of modern machine linkages, which arose during the Industrial Revolution, is inadequately described by these six simple categories. Various post-Renaissance authors have compiled expanded lists of "simple machines", often using terms like basic machines,[10] compound machines,[7] or machine elements to distinguish them from the classical simple machines above. By the late 1800s, Franz Reuleaux[12] had identified hundreds of machine elements, calling them simple machines.[13] Modern machine theory analyzes machines as kinematic chains composed of elementary linkages called kinematic pairs.

The idea of a simple machine originated with the Greek philosopher Archimedes around the 3rd century BC, who studied the Archimedean simple machines: lever, pulley, and screw.[3][14] He discovered the principle of mechanical advantage in the lever.[15]Archimedes' famous remark with regard to the lever: "Give me a place to stand on, and I will move the Earth," (Greek: δῶς μοι πᾶ στῶ καὶ τὰν γᾶν κινάσω)[16] expresses his realization that there was no limit to the amount of force amplification that could be achieved by using mechanical advantage. Later Greek philosophers defined the classic five simple machines (excluding the inclined plane) and were able to calculate their (ideal) mechanical advantage.[8] For example, Heron of Alexandria (c. 10–75 AD) in his work Mechanics lists five mechanisms that can "set a load in motion"; lever, windlass, pulley, wedge, and screw,[14] and describes their fabrication and uses.[17] However the Greeks' understanding was limited to the statics of simple machines (the balance of forces), and did not include dynamics, the tradeoff between force and distance, or the concept of work.

https://en.wikipedia.org/wiki/Simple_machine

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device or machine system. The device trades off input forces against movement to obtain a desired amplification in the output force. The model for this is the law of the lever. Machine components designed to manage forces and movement in this way are called mechanisms.[1] An ideal mechanism transmits power without adding to or subtracting from it. This means the ideal mechanism does not include a power source, is frictionless, and is constructed from rigid bodies that do not deflect or wear. The performance of a real system relative to this ideal is expressed in terms of efficiency factors that take into account departures from the ideal.

https://en.wikipedia.org/wiki/Mechanical_advantage

A cathode is the electrode from which a conventional current leaves a polarized electrical device. This definition can be recalled by using the mnemonic CCD for Cathode Current Departs. A conventional current describes the direction in which positive charges move. Electrons have a negative electrical charge, so the movement of electrons is opposite to that of the conventional current flow. Consequently, the mnemonic cathode current departs also means that electrons flow into the device's cathode from the external circuit.

The electrode through which conventional current flows the other way, into the device, is termed an anode.

https://en.wikipedia.org/wiki/Cathode

An amplifier, electronic amplifier or (informally) amp is an electronic device that can increase the power of a signal (a time-varying voltage or current). It is a two-port electronic circuit that uses electric power from a power supply to increase the amplitude of a signal applied to its input terminals, producing a proportionally greater amplitude signal at its output. The amount of amplification provided by an amplifier is measured by its gain: the ratio of output voltage, current, or power to input. An amplifier is a circuit that has a power gain greater than one.[1][2][3]

https://en.wikipedia.org/wiki/Amplifier

In signal processing, a signal is a function that conveys information about a phenomenon.[1]In electronics and telecommunications, it refers to any time varying voltage, current, or electromagnetic wave that carries information. A signal may also be defined as an observable change in a quality such as quantity.[2]

Any quality, such as physical quantity that exhibits variation in space or time can be used as a signal to share messages between observers.[3] According to the IEEE Transactions on Signal Processing, a signal can be audio, video, speech, image, sonar, and radar-related and so on.[4]

https://en.wikipedia.org/wiki/Signal

The details of a spinning body may impose restrictions on the motion of its angular velocity vector, ω. The curve produced by the angular velocity vector on the inertia ellipsoid, is known as the polhode, coined from Greek meaning "path of the pole". The surface created by the angular velocity vector is termed the body cone.

https://en.wikipedia.org/wiki/Polhode

In special and general relativity, a light cone is the path that a flash of light, emanating from a single event (localized to a single point in space and a single moment in time) and traveling in all directions, would take through spacetime.

https://en.wikipedia.org/wiki/Light_cone

The parallel axis theorem, also known as Huygens–Steiner theorem, or just as Steiner's theorem,[1] named after Christiaan Huygens and Jakob Steiner, can be used to determine the moment of inertia or the second moment of area of a rigid body about any axis, given the body's moment of inertia about a parallel axis through the object's center of gravity and the perpendiculardistance between the axes.

https://en.wikipedia.org/wiki/Parallel_axis_theorem

In physics, a pair potential is a function that describes the potential energy of two interacting objects. Examples of pair potentials include the Coulomb's law in electrodynamics, Newton's law of universal gravitation in mechanics, the Lennard-Jones potential and the Morse potential.

Pair potentials are very common in physics; exceptions are very rare. An example of a potential energy function that is not a pair potential is the three-body Axilrod-Teller potential. Another example is the Stillinger-Weber potential for silicon which includes the angle in a triangle of silicon atoms as a parameter.

https://en.wikipedia.org/wiki/Pair_potential

In physics, decompression refers to a reduction of pressure or compression, and to some extent to the consequences of a reduction of pressure. Decompression has the most obvious consequences when applied to gases or to liquids containing dissolved gases.[citation needed]

https://en.wikipedia.org/wiki/Decompression_(physics)

https://en.wikipedia.org/wiki/Category:Mechanics

In physics, the degrees of freedom (DOF) of a mechanical system is the number of independent parameters that define its configuration or state. It is important in the analysis of systems of bodies in mechanical engineering, structural engineering, aerospace engineering, robotics, and other fields.

The position of a single railcar (engine) moving along a track has one degree of freedom because the position of the car is defined by the distance along the track. A train of rigid cars connected by hinges to an engine still has only one degree of freedom because the positions of the cars behind the engine are constrained by the shape of the track.

An automobile with highly stiff suspension can be considered to be a rigid body traveling on a plane (a flat, two-dimensional space). This body has three independent degrees of freedom consisting of two components of translation and one angle of rotation. Skidding or drifting is a good example of an automobile's three independent degrees of freedom.

The position and orientation of a rigid body in space is defined by three components of translation and three components of rotation, which means that it has six degrees of freedom.

The exact constraint mechanical design method manages the degrees of freedom to neither underconstrain nor overconstrain a device.[1]

https://en.wikipedia.org/wiki/Degrees_of_freedom_(mechanics)

Dynamic balance is the branch of mechanics that is concerned with the effects of forces on the motion of a body or system of bodies, especially of forces that do not originate within the system itself, which is also called kinetics.[1][2][3]

Dynamic balance is the ability of an object to balance while in motion or switching between positions.

https://en.wikipedia.org/wiki/Dynamic_balance

Rubber elasticity refers to a property of crosslinked rubber: it can be stretched by up to a factor of 10 from its original length and, when released, returns very nearly to its original length. This can be repeated many times with no apparent degradation to the rubber. Rubber is a member of a larger class of materials called elastomers and it is difficult to overestimate their economic and technological importance. Elastomers have played a key role in the development of new technologies in the 20th century and make a substantial contribution to the global economy.[citation needed] Rubber elasticity is produced by several complex molecular processes and its explanation requires a knowledge of advanced mathematics, chemistry and statistical physics, particularly the concept of entropy. Entropy may be thought of as a measure of the thermal energy that is stored in a molecule. Common rubbers, such as polybutadiene and polyisoprene (also called natural rubber), are produced by a process called polymerization. Very long molecules (polymers) are built up sequentially by adding short molecular backbone units through chemical reactions. A rubber polymer follows a random, zigzag path in three dimensions, intermingling with many other rubber molecules. An elastomer is created by the addition of a few percent of a cross linking molecule such as sulfur. When heated, the crosslinking molecule causes a reaction that chemically joins (bonds) two of the rubber molecules together at some point (a crosslink). Because the rubber molecules are so long, each one participates in many crosslinks with many other rubber molecules forming a continuous molecular network. As a rubber band is stretched, some of the network chains are forced to become straight and this causes a decrease in their entropy. It is this decrease in entropy that gives rise to the elastic force in the network chains.

History[edit]

Following its introduction to Europe from the New World in the late 15th century, natural rubber (polyisoprene) was regarded mostly as a fascinating curiosity. Its most useful application was its ability to erase pencil marks on paper by rubbing, hence its name. One of its most peculiar properties is a slight (but detectable) increase in temperature that occurs when a sample of rubber is stretched. If it is allowed to quickly retract, an equal amount of cooling is observed. This phenomenon caught the attention of the English physicist John Gough. In 1805 he published some qualitative observations on this characteristic as well as how the required stretching force increased with temperature.[1]

By the mid nineteenth century, the theory of thermodynamics was being developed and within this framework, the English mathematician and physicist Lord Kelvin[2] showed that the change in mechanical energy required to stretch a rubber sample should be proportional to the increase in temperature. Later, this would be associated with a change in entropy. The connection to thermodynamics was firmly established in 1859 when the English physicist James Joule published the first careful measurements of the temperature increase that occurred as a rubber sample was stretched.[3] This work confirmed the theoretical predictions of Lord Kelvin.

It was not until 1838 that the American inventor Charles Goodyear found that natural rubber's properties could be immensely improved by adding a few percent sulphur. The short sulfur chains produced chemical cross-links between adjacent polyisoprenemolecules. Before it is cross-linked, the liquid natural rubber consists of very long linear chains, containing thousands of isoprenebackbone units, connected head-to-tail. Every chain follows a random path through the liquid and is in contact with thousands of other nearby chains. When heated to about 150C, cross-linker molecules (such as sulfur or dicumyl peroxide) can decompose and the subsequent chemical reactions produce a chemical bond between adjacent chains. The result is a three dimensional molecular network. All of the original polyisoprene chains are connected together at multiple points by these chemical bonds (network nodes) to form a single giant molecule. A rubber band is a single molecule, as is a latex glove! The sections between two cross-links on the same chain are called network chains and can contain up to several hundred isoprene units. In natural rubber, each cross-link produces a network node with four chains emanating from it. The network is the sine qua non of elastomers.

Because of the enormous economic and technological importance of rubber, predicting how a molecular network responds to mechanical strains has been of enduring interest to scientists and engineers. To understand the elastic properties of rubber, theoretically, it is necessary to know both the physical mechanisms that occur at the molecular level and how the random-walk nature of the polymer chain defines the network. The physical mechanisms that occur within short sections of the polymer chains produce the elastic forces and the network morphology determines how these forces combine to produce the macroscopic stressthat we observe when a rubber sample is deformed, e.g. subjected to tensile strain.

https://en.wikipedia.org/wiki/Rubber_elasticity

Drucker stability (also called the Drucker stability postulates) refers to a set of mathematical criteria that restrict the possible nonlinear stress-strain relations that can be satisfied by a solid material.[1] The postulates are named after Daniel C. Drucker. A material that does not satisfy these criteria is often found to be unstable in the sense that application of a load to a material point can lead to arbitrary deformations at that material point unless an additional length or time scale is specified in the constitutive relations.

The Drucker stability postulates are often invoked in nonlinear finite element analysis. Materials that satisfy these criteria are generally well-suited for numerical analysis, while materials that fail to satisfy this criterion are likely to present difficulties (i.e. non-uniqueness or singularity) during the solution process.

https://en.wikipedia.org/wiki/Drucker_stability

https://en.wikipedia.org/wiki/Rubber_elasticity

https://en.wikipedia.org/wiki/Normal_distribution

https://en.wikipedia.org/wiki/Probability_density_function

https://en.wikipedia.org/wiki/Boltzmann_distribution

https://en.wikipedia.org/wiki/Tortuosity

https://en.wikipedia.org/wiki/Dihedral_angle

https://en.wikipedia.org/wiki/Kuhn_length

https://en.wikipedia.org/wiki/Conditional_probability_distribution

https://en.wikipedia.org/wiki/Entropic_force

https://en.wikipedia.org/wiki/Neo-Hookean_solid

https://en.wikipedia.org/wiki/Hooke%27s_law

https://en.wikipedia.org/wiki/Elasticity_(physics)

https://en.wikipedia.org/wiki/Category:Thermodynamics

A mechanical system is rheonomous if its equations of constraints contain the time as an explicit variable.[1][2] Such constraints are called rheonomic constraints. The opposite of rheonomous is scleronomous.[1][2]

Example: simple 2D pendulum[edit]

As shown at right, a simple pendulum is a system composed of a weight and a string. The string is attached at the top end to a pivot and at the bottom end to a weight. Being inextensible, the string has a constant length. Therefore, this system is scleronomous; it obeys the scleronomic constraint

- ,

where is the position of the weight and the length of the string.

The situation changes if the pivot point is moving, e.g. undergoing a simple harmonic motion

- ,

where is the amplitude, the angular frequency, and time.

Although the top end of the string is not fixed, the length of this inextensible string is still a constant. The distance between the top end and the weight must stay the same. Therefore, this system is rheonomous; it obeys the rheonomic constraint

- .

See also[edit]

https://en.wikipedia.org/wiki/Rheonomous

https://en.wikipedia.org/wiki/Category:Lagrangian_mechanics

In classical mechanics, holonomic constraints are relations between the position variables (and possibly time[1]) that can be expressed in the following form:

where are the n generalized coordinates that describe the system. For example, the motion of a particle constrained to lie on the surface of a sphere is subject to a holonomic constraint, but if the particle is able to fall off the sphere under the influence of gravity, the constraint becomes non-holonomic. For the first case the holonomic constraint may be given by the equation:

where is the distance from the centre of a sphere of radius , whereas the second non-holonomic case may be given by:

Velocity-dependent constraints such as:

are not usually holonomic.[citation needed]

https://en.wikipedia.org/wiki/Holonomic_constraints

Directional stability is stability of a moving body or vehicle about an axis which is perpendicular to its direction of motion. Stability of a vehicle concerns itself with the tendency of a vehicle to return to its original direction in relation to the oncoming medium (water, air, road surface, etc.) when disturbed (rotated) away from that original direction. If a vehicle is directionally stable, a restoring moment is produced which is in a direction opposite to the rotational disturbance. This "pushes" the vehicle (in rotation) so as to return it to the original orientation, thus tending to keep the vehicle oriented in the original direction.

https://en.wikipedia.org/wiki/Directional_stability

In physics, a force is any influence that, when unopposed, will change the motion of an object. A force can cause an object with mass to change its velocity (which includes to begin moving from a state of rest), i.e., to accelerate. Force can also be described intuitively as a push or a pull. A force has both magnitude and direction, making it a vector quantity. It is measured in the SI unit of newton (N). Force is represented by the symbol F (formerly P).

| Property/Interaction | Gravitation | Weak | Electromagnetic | Strong | |

|---|---|---|---|---|---|

| (Electroweak) | Fundamental | Residual | |||

| Acts on: | Mass - Energy | Flavor | Electric charge | Color charge | Atomic nuclei |

| Particles experiencing: | All | Quarks, leptons | Electrically charged | Quarks, Gluons | Hadrons |

| Particles mediating: | Graviton (not yet observed) | W+ W− Z0 | γ | Gluons | Mesons |

| Strength in the scale of quarks: | 10−41 | 10−4 | 1 | 60 | Not applicable to quarks |

| Strength in the scale of protons/neutrons: | 10−36 | 10−7 | 1 | Not applicable to hadrons | 20 |

https://en.wikipedia.org/wiki/Force

https://en.wikipedia.org/wiki/Theory_of_everything

https://en.wikipedia.org/wiki/List_of_unsolved_problems_in_physics

In mathematics and physics, a scalar field or scalar-valued function associates a scalarvalue to every point in a space – possibly physical space. The scalar may either be a (dimensionless) mathematical number or a physical quantity. In a physical context, scalar fields are required to be independent of the choice of reference frame, meaning that any two observers using the same units will agree on the value of the scalar field at the same absolute point in space (or spacetime) regardless of their respective points of origin. Examples used in physics include the temperature distribution throughout space, the pressure distribution in a fluid, and spin-zero quantum fields, such as the Higgs field. These fields are the subject of scalar field theory.

https://en.wikipedia.org/wiki/Scalar_field

Buoyancy (/ˈbɔɪənsi, ˈbuːjənsi/),[1][2] or upthrust, is an upward force exerted by a fluid that opposes the weight of a partially or fully immersed object. In a column of fluid, pressure increases with depth as a result of the weight of the overlying fluid. Thus the pressure at the bottom of a column of fluid is greater than at the top of the column. Similarly, the pressure at the bottom of an object submerged in a fluid is greater than at the top of the object. The pressure difference results in a net upward force on the object. The magnitude of the force is proportional to the pressure difference, and (as explained by Archimedes' principle) is equivalent to the weight of the fluid that would otherwise occupy the submerged volume of the object, i.e. the displaced fluid.

For this reason, an object whose average density is greater than that of the fluid in which it is submerged tends to sink. If the object is less dense than the liquid, the force can keep the object afloat. This can occur only in a non-inertial reference frame, which either has a gravitational field or is accelerating due to a force other than gravity defining a "downward" direction.[3]

https://en.wikipedia.org/wiki/Buoyancy

In fluid dynamics, drag (sometimes called air resistance, a type of friction, or fluid resistance, another type of friction or fluid friction) is a force acting opposite to the relative motion of any object moving with respect to a surrounding fluid.[1] This can exist between two fluid layers (or surfaces) or a fluid and a solid surface. Unlike other resistive forces, such as dry friction, which are nearly independent of velocity, drag force depends on velocity.[2][3]

Drag force is proportional to the velocity for low-speed flow and the squared velocity for high speed flow, where the distinction between low and high speed is measured by the Reynolds number. Even though the ultimate cause of a drag is viscous friction, the turbulent drag is independent of viscosity.[4]

Drag forces always tend to decrease fluid velocity relative to the solid object in the fluid's path.

https://en.wikipedia.org/wiki/Drag_(physics)#Very_low_Reynolds_numbers_–_Stokes'_drag

In incompressible fluid dynamics dynamic pressure (indicated with , or Q, and sometimes called velocity pressure) is the quantity defined by:[1]

where (using SI units):

dynamic pressure in pascals (i.e., kg/m⋅s2), fluid mass density (e.g. in kg/m3, in SI units), flow speed in m/s.

It can be thought of as the fluid's kinetic energy per unit volume.

For incompressible flow, the dynamic pressure of a fluid is the difference between its total pressure and static pressure. From Bernoulli's law, dynamic pressure is given by

where and are the total and static pressures, respectively.

https://en.wikipedia.org/wiki/Dynamic_pressure

For example, a person standing on the ground experiences zero net force, since a normal force (a reaction force) is exerted by the ground upward on the person that counterbalances his weight that is directed downward.[3][4]

https://en.wikipedia.org/wiki/Force

Newton's Universal Gravitation Constant,[30] though its value was unknown in Newton's lifetime. Not until 1798 was Henry Cavendish able to make the first measurement of using a torsion balance; this was widely reported in the press as a measurement of the mass of the Earth since knowing could allow one to solve for the Earth's mass given the above equation.

https://en.wikipedia.org/wiki/Force

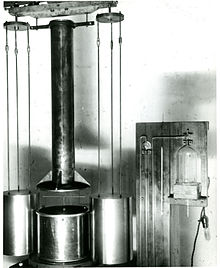

Torsion balance[edit]

The torsion balance, also called torsion pendulum, is a scientific apparatus for measuring very weak forces, usually credited to Charles-Augustin de Coulomb, who invented it in 1777, but independently invented by John Michell sometime before 1783.[3] Its most well-known uses were by Coulomb to measure the electrostatic force between charges to establish Coulomb's Law, and by Henry Cavendish in 1798 in the Cavendish experiment[4]to measure the gravitational force between two masses to calculate the density of the Earth, leading later to a value for the gravitational constant.

The torsion balance consists of a bar suspended from its middle by a thin fiber. The fiber acts as a very weak torsion spring. If an unknown force is applied at right angles to the ends of the bar, the bar will rotate, twisting the fiber, until it reaches an equilibrium where the twisting force or torque of the fiber balances the applied force. Then the magnitude of the force is proportional to the angle of the bar. The sensitivity of the instrument comes from the weak spring constant of the fiber, so a very weak force causes a large rotation of the bar.

In Coulomb's experiment, the torsion balance was an insulating rod with a metal-coated ball attached to one end, suspended by a silk thread. The ball was charged with a known charge of static electricity, and a second charged ball of the same polarity was brought near it. The two charged balls repelled one another, twisting the fiber through a certain angle, which could be read from a scale on the instrument. By knowing how much force it took to twist the fiber through a given angle, Coulomb was able to calculate the force between the balls. Determining the force for different charges and different separations between the balls, he showed that it followed an inverse-square proportionality law, now known as Coulomb's law.

To measure the unknown force, the spring constant of the torsion fiber must first be known. This is difficult to measure directly because of the smallness of the force. Cavendish accomplished this by a method widely used since: measuring the resonant vibration periodof the balance. If the free balance is twisted and released, it will oscillate slowly clockwise and counterclockwise as a harmonic oscillator, at a frequency that depends on the moment of inertia of the beam and the elasticity of the fiber. Since the inertia of the beam can be found from its mass, the spring constant can be calculated.

Coulomb first developed the theory of torsion fibers and the torsion balance in his 1785 memoir, Recherches theoriques et experimentales sur la force de torsion et sur l'elasticite des fils de metal &c. This led to its use in other scientific instruments, such as galvanometers, and the Nichols radiometer which measured the radiation pressure of light. In the early 1900s gravitational torsion balances were used in petroleum prospecting. Today torsion balances are still used in physics experiments. In 1987, gravity researcher A.H. Cook wrote:

Torsional harmonic oscillators[edit]

| Term | Unit | Definition |

|---|---|---|

| rad | Angle of deflection from rest position | |

| kg m2 | Moment of inertia | |

| joule s rad−1 | Angular damping constant | |

| N m rad−1 | Torsion spring constant | |

| Drive torque | ||

| Hz | Undamped (or natural) resonant frequency | |

| s | Undamped (or natural) period of oscillation | |

| Undamped resonant frequency in radians | ||

| Hz | Damped resonant frequency | |

| Damped resonant frequency in radians | ||

| Reciprocal of damping time constant | ||

| rad | Phase angle of oscillation | |

| m | Distance from axis to where force is applied |

Torsion balances, torsion pendulums and balance wheels are examples of torsional harmonic oscillators that can oscillate with a rotational motion about the axis of the torsion spring, clockwise and counterclockwise, in harmonic motion. Their behavior is analogous to translational spring-mass oscillators (see Harmonic oscillator Equivalent systems). The general differential equationof motion is:

If the damping is small, , as is the case with torsion pendulums and balance wheels, the frequency of vibration is very near the natural resonant frequency of the system:

Therefore, the period is represented by:

The general solution in the case of no drive force (), called the transient solution, is:

where:

Applications[edit]

The balance wheel of a mechanical watch is a harmonic oscillator whose resonant frequency sets the rate of the watch. The resonant frequency is regulated, first coarsely by adjusting with weight screws set radially into the rim of the wheel, and then more finely by adjusting with a regulating lever that changes the length of the balance spring.

In a torsion balance the drive torque is constant and equal to the unknown force to be measured , times the moment arm of the balance beam , so . When the oscillatory motion of the balance dies out, the deflection will be proportional to the force:

To determine it is necessary to find the torsion spring constant . If the damping is low, this can be obtained by measuring the natural resonant frequency of the balance, since the moment of inertia of the balance can usually be calculated from its geometry, so:

In measuring instruments, such as the D'Arsonval ammeter movement, it is often desired that the oscillatory motion die out quickly so the steady state result can be read off. This is accomplished by adding damping to the system, often by attaching a vane that rotates in a fluid such as air or water (this is why magnetic compasses are filled with fluid). The value of damping that causes the oscillatory motion to settle quickest is called the critical damping:

See also[edit]

External links[edit]

| Wikimedia Commons has media related to Torsion springs. |

- Torsion balance interactive java tutorial

- Torsion spring calculator

- Big G measurement, description of 1999 Cavendish experiment at Univ. of Washington, showing torsion balance[link broken]

- How torsion balances were used in petroleum prospecting (web archive link)

- Mechanics of torsion springs. Web archive link, accessed December 8, 2016.

- Solved mechanics problems involving springs (springs in series and in parallel)

- Milestones in the History of Springs

Brownian motion, or pedesis (from Ancient Greek: πήδησις /pɛ̌ːdɛːsis/ "leaping"), is the random motion of particles suspended in a medium (a liquid or a gas).[2]

This pattern of motion typically consists of random fluctuations in a particle's position inside a fluid sub-domain, followed by a relocation to another sub-domain. Each relocation is followed by more fluctuations within the new closed volume. This pattern describes a fluid at thermal equilibrium, defined by a given temperature. Within such a fluid, there exists no preferential direction of flow (as in transport phenomena). More specifically, the fluid's overall linear and angular momenta remain null over time. The kinetic energies of the molecular Brownian motions, together with those of molecular rotations and vibrations, sum up to the caloric component of a fluid's internal energy (the Equipartition theorem).

This motion is named after the botanist Robert Brown, who first described the phenomenon in 1827, while looking through a microscope at pollen of the plant Clarkia pulchellaimmersed in water. In 1905, almost eighty years later, theoretical physicist Albert Einsteinpublished a paper where he modeled the motion of the pollen particles as being moved by individual water molecules, making one of his first major scientific contributions.[3] The direction of the force of atomic bombardment is constantly changing, and at different times the particle is hit more on one side than another, leading to the seemingly random nature of the motion. This explanation of Brownian motion served as convincing evidence that atomsand molecules exist and was further verified experimentally by Jean Perrin in 1908. Perrin was awarded the Nobel Prize in Physics in 1926 "for his work on the discontinuous structure of matter".[4]

The many-body interactions that yield the Brownian pattern cannot be solved by a model accounting for every involved molecule. In consequence, only probabilistic models applied to molecular populations can be employed to describe it. Two such models of the statistical mechanics, due to Einstein and Smoluchowski, are presented below. Another, pure probabilistic class of models is the class of the stochastic process models. There exist sequences of both simpler and more complicated stochastic processes which converge (in the limit) to Brownian motion (see random walk and Donsker's theorem).[5][6]

The Roman philosopher-poet Lucretius' scientific poem "On the Nature of Things" (c. 60 BC) has a remarkable description of the motion of dust particles in verses 113–140 from Book II. He uses this as a proof of the existence of atoms:

Although the mingling motion of dust particles is caused largely by air currents, the glittering, tumbling motion of small dust particles is caused chiefly by true Brownian dynamics; Lucretius "perfectly describes and explains the Brownian movement by a wrong example".[8]

While Jan Ingenhousz described the irregular motion of coal dust particles on the surface of alcohol in 1785, the discovery of this phenomenon is often credited to the botanist Robert Brown in 1827. Brown was studying pollen grains of the plant Clarkia pulchellasuspended in water under a microscope when he observed minute particles, ejected by the pollen grains, executing a jittery motion. By repeating the experiment with particles of inorganic matter he was able to rule out that the motion was life-related, although its origin was yet to be explained.

The first person to describe the mathematics behind Brownian motion was Thorvald N. Thiele in a paper on the method of least squares published in 1880. This was followed independently by Louis Bachelier in 1900 in his PhD thesis "The theory of speculation", in which he presented a stochastic analysis of the stock and option markets. The Brownian motion model of the stock market is often cited, but Benoit Mandelbrot rejected its applicability to stock price movements in part because these are discontinuous.[9]

Albert Einstein (in one of his 1905 papers) and Marian Smoluchowski (1906) brought the solution of the problem to the attention of physicists, and presented it as a way to indirectly confirm the existence of atoms and molecules. Their equations describing Brownian motion were subsequently verified by the experimental work of Jean Baptiste Perrin in 1908.

https://en.wikipedia.org/wiki/Brownian_motion

https://en.wikipedia.org/wiki/Brownian_motion

https://en.wikipedia.org/wiki/Barometric_formula

https://en.wikipedia.org/wiki/Sir_George_Stokes,_1st_Baronet

https://en.wikipedia.org/wiki/Mean_free_path

https://en.wikipedia.org/wiki/Walther_Nernst

https://en.wikipedia.org/wiki/Molecular_diffusion

https://en.wikipedia.org/wiki/J._J._Thomson

https://en.wikipedia.org/wiki/Boltzmann_constant

https://en.wikipedia.org/wiki/Van_%27t_Hoff_factor

The barometric formula, sometimes called the exponential atmosphere or isothermal atmosphere, is a formula used to model how the pressure (or density) of the air changes with altitude. The pressure drops approximately by 11.3 pascals per meter in first 1000 meters above sea level.

https://en.wikipedia.org/wiki/Barometric_formula

https://en.wikipedia.org/wiki/Einstein_relation_(kinetic_theory)

https://en.wikipedia.org/wiki/Reduced_mass

https://en.wikipedia.org/wiki/Brownian_motion

https://en.wikipedia.org/wiki/Category:Mechanics

Stress resultants are simplified representations of the stress state in structural elements such as beams, plates, or shells.[1] The geometry of typical structural elements allows the internal stress state to be simplified because of the existence of a "thickness'" direction in which the size of the element is much smaller than in other directions. As a consequence the three traction components that vary from point to point in a cross-section can be replaced with a set of resultant forces and resultant moments. These are the stress resultants (also called membrane forces, shear forces, and bending moment) that may be used to determine the detailed stress state in the structural element. A three-dimensional problem can then be reduced to a one-dimensional problem (for beams) or a two-dimensional problem (for plates and shells).

Stress resultants are defined as integrals of stress over the thickness of a structural element. The integrals are weighted by integer powers the thickness coordinate z (or x3). Stress resultants are so defined to represent the effect of stress as a membrane force N(zero power in z), bending moment M (power 1) on a beam or shell (structure). Stress resultants are necessary to eliminate the zdependency of the stress from the equations of the theory of plates and shells.

https://en.wikipedia.org/wiki/Stress_resultants

In mathematics, an asymptotic expansion, asymptotic series or Poincaré expansion (after Henri Poincaré) is a formal series of functions which has the property that truncating the series after a finite number of terms provides an approximation to a given function as the argument of the function tends towards a particular, often infinite, point. Investigations by Dingle (1973) revealed that the divergent part of an asymptotic expansion is latently meaningful, i.e. contains information about the exact value of the expanded function.

The most common type of asymptotic expansion is a power series in either positive or negative powers. Methods of generating such expansions include the Euler–Maclaurin summation formula and integral transforms such as the Laplace and Mellin transforms. Repeated integration by parts will often lead to an asymptotic expansion.

Since a convergent Taylor series fits the definition of asymptotic expansion as well, the phrase "asymptotic series" usually implies a non-convergent series. Despite non-convergence, the asymptotic expansion is useful when truncated to a finite number of terms. The approximation may provide benefits by being more mathematically tractable than the function being expanded, or by an increase in the speed of computation of the expanded function. Typically, the best approximation is given when the series is truncated at the smallest term. This way of optimally truncating an asymptotic expansion is known as superasymptotics.[1] The error is then typically of the form ~ exp(−c/ε) where ε is the expansion parameter. The error is thus beyond all orders in the expansion parameter. It is possible to improve on the superasymptotic error, e.g. by employing resummation methods such as Borel resummation to the divergent tail. Such methods are often referred to as hyperasymptotic approximations.

See asymptotic analysis and big O notation for the notation used in this article.

https://en.wikipedia.org/wiki/Asymptotic_expansion

A mechanical system is scleronomous if the equations of constraints do not contain the time as an explicit variable and the equation of constraints can be described by generalized coordinates. Such constraints are called scleronomic constraints. The opposite of scleronomous is rheonomous.

https://en.wikipedia.org/wiki/Scleronomous

Sandwich theory[1][2] describes the behaviour of a beam, plate, or shell which consists of three layers—two facesheets and one core. The most commonly used sandwich theory is linear and is an extension of first order beam theory. Linear sandwich theory is of importance for the design and analysis of sandwich panels, which are of use in building construction, vehicle construction, airplane construction and refrigeration engineering.

Some advantages of sandwich construction are:

- Sandwich cross sections are composite. They usually consist of a low to moderate stiffness core which is connected with two stiff exterior facesheets. The composite has a considerably higher shear stiffness to weight ratio than an equivalent beam made of only the core material or the facesheet material. The composite also has a high tensile strength to weight ratio.

- The high stiffness of the facesheet leads to a high bending stiffness to weight ratio for the composite.

The behavior of a beam with sandwich cross-section under a load differs from a beam with a constant elastic cross section. If the radius of curvature during bending is large compared to the thickness of the sandwich beam and the strains in the component materials are small, the deformation of a sandwich composite beam can be separated into two parts

- deformations due to bending moments or bending deformation, and

- deformations due to transverse forces, also called shear deformation.

Sandwich beam, plate, and shell theories usually assume that the reference stress state is one of zero stress. However, during curing, differences of temperature between the facesheets persist because of the thermal separation by the core material. These temperature differences, coupled with different linear expansions of the facesheets, can lead to a bending of the sandwich beam in the direction of the warmer facesheet. If the bending is constrained during the manufacturing process, residual stresses can develop in the components of a sandwich composite. The superposition of a reference stress state on the solutions provided by sandwich theory is possible when the problem is linear. However, when large elastic deformations and rotations are expected, the initial stress state has to be incorporated directly into the sandwich theory.

https://en.wikipedia.org/wiki/Sandwich_theory

A differential pulley, also called "Weston differential pulley", sometimes "chain hoist" or colloquially "chain fall", is used to manually lift very heavy objects like car engines. It is operated by pulling upon the slack section of a continuous chain that wraps around pulleys. The relative size of two connected pulleys determines the maximum weight that can be lifted by hand. If the pulley radii are close enough the load will remain in place (and not lower under the force of gravity) until the chain is pulled.[1]

https://en.wikipedia.org/wiki/Differential_pulley

In physics, an energy well describes a 'stable' equilibrium that is not at lowest possible energy.

In general, modern physics holds the view that the universe - and systems therein - spontaneously drives toward a state of lower energy, if possible. For example, a bowling ball pitched atop a smooth hump (which has potential energy in the presence of gravity), will tend to roll down to the lowest point it possibly can. Once there, this reduces the total potential energy of the system.

On the other hand, if the bowling ball is resting in a valley between two humps - no matter how big the drops outside the humps - it will stay there indefinitely. Even though the system could achieve a lower energy state, it cannot do so without external energy being applied: (locally) it is at its lowest energy state, and only a force from outside the system can 'push' it over one of the humps so a lower state can be achieved.

The concept of an energy well is a key part of teaching basic physics, especially quantum mechanics. Here, students often solve the one-dimensional Schrödinger Equation for an electron trapped in a potential well from which it has insufficient energy to escape. The solution to this problem is a series of sinusoidal waves of fractional integral wavelengths determined by the width of the well.

https://en.wikipedia.org/wiki/Energy_well

A mechanical or physical shock is a sudden acceleration caused, for example, by impact, drop, kick, earthquake, or explosion. Shock is a transient physical excitation.

Shock describes matter subject to extreme rates of force with respect to time. Shock is a vector that has units of an acceleration (rate of change of velocity). The unit g (or g) represents multiples of the acceleration of gravity and is conventionally used.

A shock pulse can be characterised by its peak acceleration, the duration, and the shape of the shock pulse (half sine, triangular, trapezoidal, etc.). The Shock response spectrum is a method for further evaluating a mechanical shock.[1]

https://en.wikipedia.org/wiki/Shock_(mechanics)

https://en.wikipedia.org/wiki/Vaccum

https://en.wikipedia.org/wiki/Void

https://en.wikipedia.org/wiki/Shock_(mechanics)

https://en.wikipedia.org/wiki/Buckling

https://en.wikipedia.org/wiki/Fouling

https://en.wikipedia.org/wiki/Fracture

https://en.wikipedia.org/wiki/Mechanical_overload

https://en.wikipedia.org/wiki/Thermal_shock

https://en.wikipedia.org/wiki/Stress_corrosion_cracking

https://en.wikipedia.org/wiki/Hydrogen_embrittlement

https://en.wikipedia.org/wiki/Yield_(engineering)

https://en.wikipedia.org/wiki/Creep_(deformation)

https://en.wikipedia.org/wiki/Corrosion

https://en.wikipedia.org/wiki/Stiffening

Six degrees of freedom (6DoF) refers to the freedom of movement of a rigid body in three-dimensional space. Specifically, the body is free to change position as forward/backward (surge), up/down (heave), left/right (sway) translation in three perpendicular axes, combined with changes in orientation through rotation about three perpendicular axes, often termed yaw (normal axis), pitch (transverse axis), and roll (longitudinal axis). Three degrees of freedom (3DOF), a term often used in the context of virtual reality, refers to tracking of rotational motion only: pitch, yaw, and roll.[1][2]

https://en.wikipedia.org/wiki/Six_degrees_of_freedom

Stokes' theorem,[1] also known as Kelvin–Stokes theorem[2][3] after Lord Kelvin and George Stokes, the fundamental theorem for curls or simply the curl theorem,[4] is a theorem in vector calculus on . Given a vector field, the theorem relates the integral of the curl of the vector field over some surface, to the line integral of the vector field around the boundary of the surface. The classical Stokes' theorem can be stated in one sentence: The line integral of a vector field over a loop is equal to the flux of its curl through the enclosed surface.

Stokes' theorem is a special case of the generalized Stokes' theorem.[5][6] In particular, a vector field on can be considered as a 1-form in which case its curl is its exterior derivative, a 2-form.

https://en.wikipedia.org/wiki/Stokes%27_theorem

In discrete geometry and mechanics, structural rigidity is a combinatorial theory for predicting the flexibility of ensembles formed by rigid bodies connected by flexible linkagesor hinges.

https://en.wikipedia.org/wiki/Structural_rigidity

https://en.wikipedia.org/wiki/Linkage_(mechanical)

https://en.wikipedia.org/wiki/Hinge

In engineering, a factor of safety (FoS), also known as (and used interchangeably with) safety factor (SF), expresses how much stronger a system is than it needs to be for an intended load. Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges and buildings, but the structure's ability to carry a load must be determined to a reasonable accuracy.

Many systems are intentionally built much stronger than needed for normal usage to allow for emergency situations, unexpected loads, misuse, or degradation (reliability).

https://en.wikipedia.org/wiki/Factor_of_safety

The four-point flexural test provides values for the modulus of elasticity in bending , flexural stress , flexural strain and the flexural stress-strain response of the material. This test is very similar to the three-point bending flexural test. The major difference being that with the addition of a fourth bearing the portion of the beam between the two loading points is put under maximum stress, as opposed to only the material right under the central bearing in the case of three point bending.

This difference is of prime importance when studying brittle materials, where the number and severity of flaws exposed to the maximum stress is directly related to the flexural strength and crack initiation. Compared to the three-point bending flexural test, there are no shear forces in the four-point bending flexural test in the area between the two loading pins.[1] The four-point bending test is therefore particularly suitable for brittle materials that cannot withstand shear stresses very well.

It is one of the most widely used apparatus to characterize fatigue and flexural stiffness of asphalt mixtures.[2]

https://en.wikipedia.org/wiki/Four-point_flexural_test

In mechanics, suspension is a system of components allowing a machine (normally a vehicle) to move smoothly with reduced shock.

Types may include:

- car suspension, four-wheeled motor vehicle suspension

- motorcycle suspension, two-wheeled motor vehicle suspension

- Motorcycle fork, a component of motorcycle suspension system

- bicycle suspension

Related concepts include:

See also[edit]

A herpolhode is the curve traced out by the endpoint of the angular velocity vector ω of a rigid rotor, a rotating rigid body. The endpoint of the angular velocity moves in a plane in absolute space, called the invariable plane, that is orthogonal to the angular momentum vector L. The fact that the herpolhode is a curve in the invariable plane appears as part of Poinsot's construction.

The trajectory of the angular velocity around the angular momentum in the invariable plane is a circle in the case of a symmetric top, but in the general case wiggles inside an annulus, while still being concave towards the angular momentum.

See also[edit]

Hoop stress[edit]

The hoop stress is the force over area exerted circumferentially (perpendicular to the axis and the radius of the object) in both directions on every particle in the cylinder wall. It can be described as:

where:

- F is the force exerted circumferentially on an area of the cylinder wall that has the following two lengths as sides:

- t is the radial thickness of the cylinder

- l is the axial length of the cylinder.

An alternative to hoop stress in describing circumferential stress is wall stress or wall tension (T), which usually is defined as the total circumferential force exerted along the entire radial thickness:[3]

Along with axial stress and radial stress, circumferential stress is a component of the stress tensor in cylindrical coordinates.