Membrane bioreactor (MBR) is a combination of membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment.[1] In general, there are two different MBR configurations; (1) submerged membrane bioreactor (SMBR) and (2) side stream membrane bioreactor. [2] In the first configuration, the membrane is located inside the biological reactor, submerged in the wastewater. In the latter configuration, the membrane is located outside the reactor, as an additional step after biological treatment.

https://en.wikipedia.org/wiki/Membrane_bioreactor

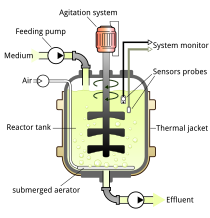

A bioreactor refers to any manufactured device or system that supports a biologically active environment.[1] In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel.[citation needed] It may also refer to a device or system designed to grow cellsor tissues in the context of cell culture.[2] These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.[citation needed]

On the basis of mode of operation, a bioreactor may be classified as batch, fed batch or continuous (e.g. a continuous stirred-tank reactor model). An example of a continuous bioreactor is the chemostat.[citation needed]Bioreactors are highly nonlinear and many novel control strategies have been proposed for their control.[3]

Organisms growing in bioreactors may be submerged in liquid medium or may be attached to the surface of a solid medium. Submerged cultures may be suspended or immobilized. Suspension bioreactors can use a wider variety of organisms, since special attachment surfaces are not needed, and can operate at a much larger scale than immobilized cultures. However, in a continuously operated process the organisms will be removed from the reactor with the effluent. Immobilization is a general term describing a wide variety of methods for cell or particle attachment or entrapment.[4] It can be applied to basically all types of biocatalysis including enzymes, cellular organelles, animal and plant cells and organs.[5][6] Immobilization is useful for continuously operated processes, since the organisms will not be removed with the reactor effluent, but is limited in scale because the microbes are only present on the surfaces of the vessel.

Large scale immobilized cell bioreactors are:

- moving media, also known as moving bed biofilm reactor (MBBR)

- packed bed

- fibrous bed

- membrane

https://en.wikipedia.org/wiki/Holographic_optical_element

08-26-2021-1541 - Nanoreactors

Robert Lee Moore | |

|---|---|

R. L. Moore in 1904 | |

| Born | November 14, 1882 Dallas, Texas |

| Died | October 4, 1974 (aged 91) Austin, Texas |

| Nationality | American |

| Alma mater | University of Chicago (Ph.D., 1905) |

| Scientific career | |

| Fields | Mathematics |

| Institutions | University of Texas at Austin |

| Thesis | Sets of Metrical Hypotheses for Geometry (1905) |

| Doctoral advisor | Oswald Veblen E. H. Moore |

| Doctoral students | |

Prejudice[edit]

Moore's record as a teacher of mathematics has been tarnished by his racism towards black students.[3][4] Most of Moore's career was spent in a racially segregated part of the United States. African-American students were prohibited from even enrolling at the University of Texas until the late 1950s,[5] and Moore himself was strongly in favor of segregation.[6][7][8][9] After the University of Texas began admitting African-American students, he refused to allow them into his classes, even for mathematics graduate students such as Vivienne Malone-Mayes.[3][4][7][8] He told another African-American mathematics student, Walker E. Hunt, "you are welcome to take my course but you start with a C and can only go down from there".[9] On one occasion he walked out of a talk by a student, his academic grandchild, after discovering that the speaker was African-American.[4][7][8]

Moore was also known for repeatedly claiming that female students were inferior to male students, and, though "less pronounced than his racism", for his antisemitism.[4]However, while Moore's racism is confirmed by several first-hand accounts of his refusal to teach African-American students, the often-repeated description of him as a misogynist and antisemite is based largely on his oral remarks. Some of the sources reporting these remarks, such as Mary Ellen Rudin, also point out that in fact he encouraged females who showed mathematical talent and that he had Jewish students, such as Edwin E. Moise (who was asked about Moore's anti-Semitic reputation in an interview)[10]and Martin Ettlinger, and close colleagues, such as Hyman J. Ettlinger. His encouragement of Rudin and other white female students is documented[11] and between 1949 and 1970 (the earliest period when national data are known) 4 of Moore's 31 doctoral students (13%) were female, while nationally 175 were female out of 2646 doctoral graduates in mathematics and statistics (7%).[12]

https://en.wikipedia.org/wiki/Hermetic_seal

https://en.wikipedia.org/wiki/Oxygen_transmission_rate

https://en.wikipedia.org/wiki/Lubricant

https://en.wikipedia.org/wiki/Solvent

https://en.wikipedia.org/wiki/Proton

https://en.wikipedia.org/wiki/Phonon

https://en.wikipedia.org/wiki/Igor_Tamm

https://en.wikipedia.org/wiki/Condensed_matter_physics

https://en.wikipedia.org/wiki/Clock_generator

https://en.wikipedia.org/wiki/Mirror

https://en.wikipedia.org/wiki/Vacuum

See also[edit]

- Zero-point energy, the minimum energy a quantum mechanical system may have

- Zero-point field, a synonym for the vacuum state in quantum field theory

- Hofstadter zero-point, a special point associated with every plane triangle

- Point of origin (disambiguation)

- Triple zero (disambiguation)

- Point Zero (disambiguation)

https://en.wikipedia.org/wiki/Zero_point

https://en.wikipedia.org/wiki/Nucleic_acid_analogue

- Phosphorous acid disproportionates upon heating to give phosphoric acid and phosphine:

- 4 H

3PO

3 → 3 H3PO4 + PH3

radioligand

phosphor rad trans

hydrogen oxygen ozone trihydrocat hydrag prop hydrazine proton phonon pholton mirror matter vacume dark matter plane formsalt salt water air atmosphere water triangle triplet material rock iodine triiodine cationcyclic triatom hydro PH4 hydro solvent oxygen lube oxy tri cascade

Ligands[edit]

Neon can form a very weak bond to a transition metal atom as a ligand, for example Cr(CO)5Ne,[15] Mo(CO)5Ne, and W(CO)5Ne.[16]

NeNiCO is predicted to have a binding energy of 2.16 kcal/mol. The presence of neon changes the bending frequency of Ni−C−O by 36 cm−1.[17][18]

NeAuF[19] and NeBeS[20] have been isolated in noble gas matrixes.[21] NeBeCO3 has been detected by infrared spectroscopy in a solid neon matrix. It was made from beryllium gas, dioxygen and carbon monoxide.[16]

The cyclic molecule Be2O2 can be made by evaporating Be with a laser with oxygen and an excess of inert gas. It coordinates two noble gas atoms and has had spectra measured in solid neon matrices. Known neon containing molecules are the homoleptic Ne.Be2O2.Ne, and heteroleptic Ne.Be2O2.Ar and Ne.Be2O2.Kr. The neon atoms are attracted to the beryllium atoms as they have a positive charge in this molecule.[22]

Beryllium sulfite molecules BeO2S, can also coordinate neon onto the beryllium atom. The dissociation energy for neon is 0.9 kcal/mol. When neon is added to the cyclic molecule, the ∠O-Be-O decreases and the O-Be bond lengths increase.[23]

Solids[edit]

High pressure Van der Waals solids include (N2)6Ne7.[24]

Neon hydrate or neon clathrate, a clathrate, can form in ice II at 480 MPa pressure between 70 K and 260 K.[25] Other neon hydrates are also predicted resembling hydrogen clathrate, and those clathrates of helium. These include the C0, ice Ih and ice Ic forms.[25]

Neon atoms can be trapped inside fullerenes such as C60 and C70. The isotope 22Ne is strongly enriched in carbonaceous chondrite meteorites, by more than 1,000 times its occurrence on Earth. This neon is given off when a meteorite is heated.[26] An explanation for this is that originally when carbon was condensing from the aftermath of a supernova explosion, cages of carbon form that preferentially trap sodium atoms, including 22Na. Forming fullerenes trap sodium orders of magnitude more often than neon, so Na@C60 is formed. rather than the more common 20Ne@C60. The 22Na@C60 then decays radioactively to 22Ne@C60, without any other neon isotopes.[27] To make buckyballs with neon inside, buckminsterfullerene can be heated to 600 °C with neon under pressure. With three atmospheres for one hour, about 1 in 8,500,000 molecules end up with Ne@C60. The concentration inside the buckyballs is about the same as in the surrounding gas. This neon comes back out when heated to 900 °C.[28]

Matrix isolation wideband amplifier

https://en.wikipedia.org/wiki/Hygrometer#Chilled_mirror_hygrometer

https://en.wikipedia.org/wiki/Ice_accretion_indicator

https://en.wikipedia.org/wiki/Gaseous_signaling_molecules

https://en.wikipedia.org/wiki/Tar#Wood_tar

https://en.wikipedia.org/wiki/Dry_distillation

https://en.wikipedia.org/wiki/Catagenesis_(geology)

https://en.wikipedia.org/wiki/Flash_vacuum_pyrolysis

https://en.wikipedia.org/wiki/Disproportionation

The holographic principle is a tenet of string theories and a supposed property of quantum gravity that states that the description of a volume of space can be thought of as encoded on a lower-dimensional boundary to the region—such as a light-like boundary like a gravitational horizon.

https://en.wikipedia.org/wiki/Holographic_principle

The hologenome theory of evolution[1][2][3][4] recasts the individual animal or plant (and other multicellular organisms) as a community or a "holobiont" – the host plus all of its symbiotic microbes. Consequently, the collective genomes of the holobiont form a "hologenome". Holobionts and hologenomes are structural entities[5] that replace misnomers in the context of host-microbiota symbioses such as superorganism (i.e., an integrated social unit composed of conspecifics), organ, and metagenome. Variation in the hologenome may encode phenotypic plasticity of the holobiont and can be subject to evolutionary changes caused by selection and drift, if portions of the hologenome are transmitted between generations with reasonable fidelity. One of the important outcomes of recasting the individual as a holobiont subject to evolutionary forces is that genetic variation in the hologenome can be brought about by changes in the host genome and also by changes in the microbiome, including new acquisitions of microbes, horizontal gene transfers, and changes in microbial abundance within hosts. Although there is a rich literature on binary host–microbe symbioses, the hologenome concept distinguishes itself by including the vast symbiotic complexity inherent in many multicellular hosts. For recent literature on holobionts and hologenomes published in an open access platform, see the following reference.[4]

https://en.wikipedia.org/wiki/Hologenome_theory_of_evolution

Holographic optical element (HOE) is an optical component (mirror, lens, directional diffuser, etc.) that produces holographic images using principles of diffraction. HOE is most commonly used in transparent displays, 3D imaging, and certain scanning technologies. The shape and structure of the HOE is dependent on the piece of hardware it is needed for, and the coupled wave theory is a common tool used to calculate the diffraction efficiency or grating volume that helps with the design of an HOE. Early concepts of the holographic optical element can be traced back to the mid-1900s, coinciding closely with the start of holography coined by Dennis Gabor. The application of 3D visualization and displays is ultimately the end goal of the HOE; however, the cost and complexity of the device has hindered the rapid development toward full 3D visualization. The HOE is also used in the development of augmented reality(AR) by companies such as Google with Google Glass or in research universities that look to utilize HOEs to create 3D imaging without the use of eye-wear or head-wear. Furthermore, the ability of the HOE to allow for transparent displays have caught the attention of the US military in its development of better head-up displays (HUD) which is used to display crucial information for aircraft pilots.[1][2][3]

https://en.wikipedia.org/wiki/Holographic_optical_element

Photobioreactor[edit]

A photobioreactor (PBR) is a bioreactor which incorporates some type of light source (that may be natural sunlight or artificial illumination). Virtually any translucent container could be called a PBR, however the term is more commonly used to define a closed system, as opposed to an open storage tank or pond. Photobioreactors are used to grow small phototrophic organisms such as cyanobacteria, algae, or moss plants.[7]These organisms use light through photosynthesis as their energy source and do not require sugars or lipids as energy source. Consequently, risk of contamination with other organisms like bacteria or fungi is lower in photobioreactors when compared to bioreactors for heterotrophorganisms.[citation needed]

Sewage treatment[edit]

Conventional sewage treatment utilises bioreactors to undertake the main purification processes. In some of these systems, a chemically inert medium with very high surface area is provided as a substrate for the growth of biological film. Separation of excess biological film takes place in settling tanks or cyclones. In other systems aerators supply oxygen to the sewage and biota to create activated sludge in which the biological component is freely mixed in the liquor in "flocs". In these processes, the liquid's biochemical oxygen demand (BOD) is reduced sufficiently to render the contaminated water fit for reuse. The biosolids can be collected for further processing, or dried and used as fertilizer. An extremely simple version of a sewage bioreactor is a septic tank whereby the sewage is left in situ, with or without additional media to house bacteria. In this instance, the biosludge itself is the primary host for the bacteria.[citation needed]

Bioreactors for specialized tissues[edit]

Many cells and tissues, especially mammalian ones, must have a surface or other structural support in order to grow, and agitated environments are often destructive to these cell types and tissues. Higher organisms, being auxotrophic, also require highly specialized growth media. This poses a challenge when the goal is to culture larger quantities of cells for therapeutic production purposes, and a significantly different design is needed compared to industrial bioreactors used for growing protein expression systems such as yeast and bacteria.[citation needed]

Many research groups have developed novel bioreactors for growing specialized tissues and cells on a structural scaffold, in attempt to recreate organ-like tissue structures in-vitro. Among these include tissue bioreactors that can grow heart tissue,[8][9] skeletal muscle tissue,[10] ligaments, cancer tissue models, and others. Currently, scaling production of these specialized bioreactors for industrial use remains challenging and is an active area of research.

For more information on artificial tissue culture, see tissue engineering.

Modelling[edit]

Mathematical models act as an important tool in various bio-reactor applications including wastewater treatment. These models are useful for planning efficient process controlstrategies and predicting the future plant performance. Moreover, these models are beneficial in education and research areas.[citation needed]

Bioreactors are generally used in those industries which are concerned with food, beverages and pharmaceuticals. The emergence of Biochemical engineering is of recent origin. Processing of biological materials using biological agents such as cells, enzymes or antibodies are the major pillars of biochemical engineering. Applications of biochemical engineering cover major fields of civilization such as agriculture, food and healthcare, resource recovery and fine chemicals.[citation needed]

Until now, the industries associated with biotechnology have lagged behind other industries in implementing control over the process and optimization strategies.[3] A main drawback in biotechnological process control is the problem of measuring key physical and biochemical parameters.[11]

Operational stages in a bio-process[edit]

A bioprocess is composed mainly of three stages — upstream processing, bioreaction, and downstream processing — to convert raw material to finished product.[12]

The raw material can be of biological or non-biological origin. It is first converted to a more suitable form for processing. This is done in an upstream processing step which involves chemical hydrolysis, preparation of liquid medium, separation of particulate, air purification and many other preparatory operations.[citation needed]

After the upstream processing step, the resulting feed is transferred to one or more bioreaction stages. The biochemical reactors or bioreactors form the base of the bioreaction step. This step mainly consists of three operations, namely, production of biomass, metabolite biosynthesis and biotransformation.[citation needed]

Finally, the material produced in the bioreactor must be further processed in the downstream section to convert it into a more useful form. The downstream process mainly consists of physical separation operations which include solid liquid separation, adsorption, liquid-liquid extraction, distillation, drying etc.[13]

Specifications[edit]

A typical bioreactor consists of following parts:

Agitator – Used for the mixing of the contents of the reactor which keeps the cells in the perfect homogenous condition for better transport of nutrients and oxygen to the desired product(s).

Baffle – Used to break the vortex formation in the vessel, which is usually highly undesirable as it changes the center of gravity of the system and consumes additional power.

Sparger – In aerobic cultivation process, the purpose of the sparger is to supply adequate oxygen to the growing cells.

Jacket – The jacket provides the annular area for circulation of constant temperature of water which keeps the temperature of the bioreactor at a constant value.[14]

https://en.wikipedia.org/wiki/Bioreactor

A Hollow fiber bioreactor is a 3 dimensional cell culturing system based on hollow fibers, which are small, semi-permeable capillary membranes arranged in parallel array with a typical molecular weight cut-off (MWCO) range of 10-30 kDa. These hollow fiber membranes are often bundled and housed within tubular polycarbonate shells to create hollow fiber bioreactor cartridges. Within the cartridges, which are also fitted with inlet and outlet ports, are two compartments: the intracapillary (IC) space within the hollow fibers, and the extracapillary (EC) space surrounding the hollow fibers.

https://en.wikipedia.org/wiki/Hollow_fiber_bioreactor

Tissue engineering is a biomedical engineering discipline that uses a combination of cells, engineering, materials methods, and suitable biochemical and physicochemical factors to restore, maintain, improve, or replace different types of biological tissues. Tissue engineering often involves the use of cells placed on tissue scaffolds in the formation of new viable tissue for a medical purpose but is not limited to applications involving cells and tissue scaffolds. While it was once categorized as a sub-field of biomaterials, having grown in scope and importance it can be considered as a field in its own.

https://en.wikipedia.org/wiki/Tissue_engineering

Production by algae[edit]

The biological hydrogen production with algae is a method of photobiological water splitting which is done in a closed photobioreactor based on the production of hydrogen as a solar fuel by algae.[6][7] Algae produce hydrogen under certain conditions. In 2000 it was discovered that if C. reinhardtii algae are deprived of sulfur they will switch from the production of oxygen, as in normal photosynthesis, to the production of hydrogen.[8][9][10]

Photosynthesis[edit]

Photosynthesis in cyanobacteria and green algae splits water into hydrogen ions and electrons. The electrons are transported over ferredoxins.[12] Fe-Fe-hydrogenases (enzymes) combine them into hydrogen gas. In Chlamydomonas reinhardtii Photosystem II produces in direct conversion of sunlight 80% of the electrons that end up in the hydrogen gas.[13]Light-harvesting complex photosystem II light-harvesting protein LHCBM9 promotes efficient light energy dissipation.[14]The Fe-Fe-hydrogenases need an anaerobic environment as they are inactivated by oxygen. Fourier transform infrared spectroscopy is used to examine metabolic pathways.[15] In 2020 scientists reported the development of algal-cell based micro-droplets for multicellular spheroid microbial reactors capable of producing hydrogen alongside either oxygen or CO2via photosynthesis in daylight under air. Enclosing the microreactors with synergistic bacteria was shown to increase levels of hydrogen production.[16][11]

Specialized chlorophyll[edit]

The chlorophyll (Chl) antenna size in green algae is minimized, or truncated, to maximize photobiological solar conversion efficiency and H2 production. The truncated Chl antenna size minimizes absorption and wasteful dissipation of sunlight by individual cells, resulting in better light utilization efficiency and greater photosynthetic productivity by the green alga mass culture.[17]

Economics[edit]

It would take about 25,000 square kilometre algal farming to produce biohydrogen equivalent to the energy provided by gasoline in the US alone. This area represents approximately 10% of the area devoted to growing soya in the US.[18]

Bioreactor design issues[edit]

- Restriction of photosynthetic hydrogen production by accumulation of a proton gradient.

- Competitive inhibition of photosynthetic hydrogen production by carbon dioxide.

- Requirement for bicarbonate binding at photosystem II (PSII) for efficient photosynthetic activity.

- Competitive drainage of electrons by oxygen in algal hydrogen production.

- Economics must reach competitive price to other sources of energy and the economics are dependent on several parameters.

- A major technical obstacle is the efficiency in converting solar energy into chemical energy stored in molecular hydrogen.

Attempts are in progress to solve these problems via bioengineering.

History[edit]

In 1933, Marjory Stephenson and her student Stickland reported that cell suspensions catalysed the reduction of methylene blue with H2. Six years later, Hans Gaffron observed that the green photosynthetic alga Chlamydomonas reinhardtii, would sometimes produce hydrogen.[19] In the late 1990s Anastasios Melis discovered that deprivation of sulfur induces the alga to switch from the production of oxygen (normal photosynthesis) to the production of hydrogen. He found that the enzyme responsible for this reaction is hydrogenase, but that the hydrogenase lost this function in the presence of oxygen. Melis also discovered that depleting the amount of sulfur available to the algae interrupted their internal oxygen flow, allowing the hydrogenase an environment in which it can react, causing the algae to produce hydrogen.[20] Chlamydomonas moewusii is also a promising strain for the production of hydrogen.[21][22]

Industrial hydrogen[edit]

Competing for biohydrogen, at least for commercial applications, are many mature industrial processes. Steam reforming of natural gas - sometimes referred to as steam methane reforming (SMR) - is the most common method of producing bulk hydrogen at about 95% of the world production.[23][24][25]

See also[edit]

Synthesis[edit]

A number of different methods have been described in the literature for preparing porous structures to be employed as tissue engineering scaffolds. Each of these techniques presents its own advantages, but none are free of drawbacks.

Nanofiber self-assembly[edit]

Molecular self-assembly is one of the few methods for creating biomaterials with properties similar in scale and chemistry to that of the natural in vivo extracellular matrix (ECM), a crucial step toward tissue engineering of complex tissues.[45] Moreover, these hydrogel scaffolds have shown superiority in in vivo toxicology and biocompatibility compared to traditional macro-scaffolds and animal-derived materials.

Textile technologies[edit]

These techniques include all the approaches that have been successfully employed for the preparation of non-woven meshes of different polymers. In particular, non-woven polyglycolide structures have been tested for tissue engineering applications: such fibrous structures have been found useful to grow different types of cells. The principal drawbacks are related to the difficulties in obtaining high porosityand regular pore size.

Solvent casting and particulate leaching[edit]

Solvent casting and particulate leaching (SCPL) allows for the preparation of structures with regular porosity, but with limited thickness. First, the polymer is dissolved into a suitable organic solvent (e.g. polylactic acid could be dissolved into dichloromethane), then the solution is cast into a mold filled with porogen particles. Such porogen can be an inorganic salt like sodium chloride, crystals of saccharose, gelatin spheres or paraffin spheres. The size of the porogen particles will affect the size of the scaffold pores, while the polymer to porogen ratio is directly correlated to the amount of porosity of the final structure. After the polymer solution has been cast the solvent is allowed to fully evaporate, then the composite structure in the mold is immersed in a bath of a liquid suitable for dissolving the porogen: water in the case of sodium chloride, saccharose and gelatin or an aliphatic solvent like hexane for use with paraffin. Once the porogen has been fully dissolved, a porous structure is obtained. Other than the small thickness range that can be obtained, another drawback of SCPL lies in its use of organic solvents which must be fully removed to avoid any possible damage to the cells seeded on the scaffold.

Gas foaming[edit]

To overcome the need to use organic solvents and solid porogens, a technique using gas as a porogen has been developed. First, disc-shaped structures made of the desired polymer are prepared by means of compression molding using a heated mold. The discs are then placed in a chamber where they are exposed to high pressure CO2 for several days. The pressure inside the chamber is gradually restored to atmospheric levels. During this procedure the pores are formed by the carbon dioxide molecules that abandon the polymer, resulting in a sponge-like structure. The main problems resulting from such a technique are caused by the excessive heat used during compression molding (which prohibits the incorporation of any temperature labile material into the polymer matrix) and by the fact that the pores do not form an interconnected structure.

Emulsification freeze-drying[edit]

This technique does not require the use of a solid porogen like SCPL. First, a synthetic polymer is dissolved into a suitable solvent (e.g. polylactic acid in dichloromethane) then water is added to the polymeric solution and the two liquids are mixed in order to obtain an emulsion. Before the two phases can separate, the emulsion is cast into a mold and quickly frozen by means of immersion into liquid nitrogen. The frozen emulsion is subsequently freeze-dried to remove the dispersed water and the solvent, thus leaving a solidified, porous polymeric structure. While emulsification and freeze-drying allow for a faster preparation when compared to SCPL (since it does not require a time-consuming leaching step), it still requires the use of solvents. Moreover, pore size is relatively small and porosity is often irregular. Freeze-drying by itself is also a commonly employed technique for the fabrication of scaffolds. In particular, it is used to prepare collagen sponges: collagen is dissolved into acidic solutions of acetic acid or hydrochloric acid that are cast into a mold, frozen with liquid nitrogen and then lyophilized.

Thermally induced phase separation[edit]

Similar to the previous technique, the TIPS phase separation procedure requires the use of a solvent with a low melting point that is easy to sublime. For example, dioxane could be used to dissolve polylactic acid, then phase separation is induced through the addition of a small quantity of water: a polymer-rich and a polymer-poor phase are formed. Following cooling below the solvent melting point and some days of vacuum-drying to sublime the solvent, a porous scaffold is obtained. Liquid-liquid phase separation presents the same drawbacks of emulsification/freeze-drying.[46]

Electrospinning[edit]

Electrospinning is a highly versatile technique that can be used to produce continuous fibers ranging in diameter from a few microns to a few nanometers. In a typical electrospinning set-up, the desired scaffold material is dissolved within a solvent and placed within a syringe. This solution is fed through a needle and a high voltage is applied to the tip and to a conductive collection surface. The buildup of electrostatic forces within the solution causes it to eject a thin fibrous stream towards the oppositely charged or grounded collection surface. During this process the solvent evaporates, leaving solid fibers leaving a highly porous network. This technique is highly tunable, with variation to solvent, voltage, working distance (distance from the needle to collection surface), flow rate of solution, solute concentration, and collection surface. This allows for precise control of fiber morphology.

On a commercial level however, due to scalability reasons, there are 40 or sometimes 96 needles involved operating at once. The bottle-necks in such set-ups are: 1) Maintaining the aforementioned variables uniformly for all of the needles and 2) formation of "beads" in single fibers that we as engineers, want to be of a uniform diameter. By modifying variables such as the distance to collector, magnitude of applied voltage, or solution flow rate – researchers can dramatically change the overall scaffold architecture.

Historically, research on electrospun fibrous scaffolds dates back to at least the late 1980s when Simon showed that electrospinning could be used to produced nano- and submicron-scale fibrous scaffolds from polymer solutions specifically intended for use as in vitro cell and tissue substrates. This early use of electrospun lattices for cell culture and tissue engineering showed that various cell types would adhere to and proliferate upon polycarbonate fibers. It was noted that as opposed to the flattened morphology typically seen in 2D culture, cells grown on the electrospun fibers exhibited a more rounded 3-dimensional morphology generally observed of tissues in vivo.[47]

CAD/CAM technologies[edit]

Because most of the above techniques are limited when it comes to the control of porosity and pore size, computer assisted design and manufacturing techniques have been introduced to tissue engineering. First, a three-dimensional structure is designed using CAD software. The porosity can be tailored using algorithms within the software.[48] The scaffold is then realized by using ink-jet printing of polymer powders or through Fused Deposition Modeling of a polymer melt.[49]

A 2011 study by El-Ayoubi et al. investigated "3D-plotting technique to produce (biocompatible and biodegradable) poly-L-Lactide macroporous scaffolds with two different pore sizes" via solid free-form fabrication (SSF) with computer-aided-design (CAD), to explore therapeutic articular cartilage replacement as an "alternative to conventional tissue repair".[50] The study found the smaller the pore size paired with mechanical stress in a bioreactor (to induce in vivo-like conditions), the higher the cell viability in potential therapeutic functionality via decreasing recovery time and increasing transplant effectiveness.[50]

Laser-assisted bioprinting[edit]

In a 2012 study,[51] Koch et al. focused on whether Laser-assisted BioPrinting (LaBP) can be used to build multicellular 3D patterns in natural matrix, and whether the generated constructs are functioning and forming tissue. LaBP arranges small volumes of living cell suspensions in set high-resolution patterns.[51] The investigation was successful, the researchers foresee that "generated tissue constructs might be used for in vivo testing by implanting them into animal models" (14). As of this study, only human skin tissue has been synthesized, though researchers project that "by integrating further cell types (e.g. melanocytes, Schwann cells, hair follicle cells) into the printed cell construct, the behavior of these cells in a 3D in vitro microenvironment similar to their natural one can be analyzed", which is useful for drug discovery and toxicology studies.[51]

Self-assembled recombinant spider silk nanomembranes[edit]

Gustafsson et al.[52] demonstrated free‐standing, bioactive membranes of cm-sized area, but only 250 nm thin, that were formed by self‐assembly of spider silk at the interface of an aqueous solution. The membranes uniquely combine nanoscale thickness, biodegradability, ultrahigh strain and strength, permeability to proteins and promote rapid cell adherence and proliferation. They demonstrated growing a coherent layer of keratinocytes. These spider silk nanomembranes have also been used to create a static in-vitromodel of a blood vessel.[53]

https://en.wikipedia.org/wiki/Tissue_engineering

A Grape Made of... Meat?? - Tissue Recellularization

https://youtu.be/FaVHTd9Ne_s

matrix microwave junction baking powder riser etc.

No comments:

Post a Comment