The stability of a chemical compound is eventually limited when exposed to extreme environmental conditions such as heat, radiation, humidity, or the acidity of a solvent. Because of this chemical decomposition is often an undesired chemical reaction. However chemical decomposition can be desired, such as in various waste treatment processes.

https://en.wikipedia.org/wiki/Chemical_decomposition

Energy storage is the capture of energy produced at one time for use at a later time[1] to reduce imbalances between energy demand and energy production. A device that stores energy is generally called an accumulator or battery. Energy comes in multiple forms including radiation, chemical, gravitational potential, electrical potential, electricity, elevated temperature, latent heat and kinetic. Energy storage involves converting energy from forms that are difficult to store to more conveniently or economically storable forms.

Some technologies provide short-term energy storage, while others can endure for much longer. Bulk energy storage is currently dominated by hydroelectric dams, both conventional as well as pumped. Grid energy storage is a collection of methods used for energy storage on a large scale within an electrical power grid.

Common examples of energy storage are the rechargeable battery, which stores chemical energy readily convertible to electricity to operate a mobile phone; the hydroelectric dam, which stores energy in a reservoir as gravitational potential energy; and ice storage tanks, which store ice frozen by cheaper energy at night to meet peak daytime demand for cooling. Green hydrogen, from electrolysis of water, is a more economical means of long-term renewable energy storage in terms of capital expenditures than pumped-storage hydroelectricity or batteries.[2][3] Fossil fuels such as coal and gasoline store ancient energy derived from sunlight by organisms that later died, became buried and over time were then converted into these fuels. Food (which is made by the same process as fossil fuels) is a form of energy stored in chemical form.

History

In the 20th century grid, electrical power was largely generated by burning fossil fuel. When less power was required, less fuel was burned.[4] Hydropower, a mechanical energy storage method, is the most widely adopted mechanical energy storage, and has been in use for centuries. Large hydropower dams have been energy storage sites for more than one hundred years.[5] Concerns with air pollution, energy imports, and global warming have spawned the growth of renewable energy such as solar and wind power.[4] Wind power is uncontrolled and may be generating at a time when no additional power is needed. Solar power varies with cloud cover and at best is only available during daylight hours, while demand often peaks after sunset (see duck curve). Interest in storing power from these intermittent sources grows as the renewable energy industry begins to generate a larger fraction of overall energy consumption.[6]

Off grid electrical use was a niche market in the 20th century, but in the 21st century, it has expanded. Portable devices are in use all over the world. Solar panels are now common in the rural settings worldwide. Access to electricity is now a question of economics and financial viability, and not solely on technical aspects. Electric vehicles are gradually replacing combustion-engine vehicles. However, powering long-distance transportation without burning fuel remains in development.

Methods

Outline

The following list includes a variety of types of energy storage:

- Fossil fuel storage

- Mechanical

- Spring

- Compressed air energy storage (CAES)

- Fireless locomotive

- Flywheel energy storage

- Solid mass gravitational

- Hydraulic accumulator

- Pumped-storage hydroelectricity (pumped hydroelectric storage, PHS, or pumped storage hydropower, PSH)

- Thermal Expansion

- Electrical, electromagnetic

- Capacitor

- Supercapacitor

- Superconducting magnetic energy storage (SMES, also superconducting storage coil)

- Biological

- Electrochemical (Battery Energy Storage System, BESS)

- Thermal

- Chemical

Mechanical

Energy can be stored in water pumped to a higher elevation using pumped storage methods or by moving solid matter to higher locations (gravity batteries). Other commercial mechanical methods include compressing air and flywheels that convert electric energy into internal energy or kinetic energy and then back again when electrical demand peaks.

Hydroelectricity

Hydroelectric dams with reservoirs can be operated to provide electricity at times of peak demand. Water is stored in the reservoir during periods of low demand and released when demand is high. The net effect is similar to pumped storage, but without the pumping loss.

While a hydroelectric dam does not directly store energy from other generating units, it behaves equivalently by lowering output in periods of excess electricity from other sources. In this mode, dams are one of the most efficient forms of energy storage, because only the timing of its generation changes. Hydroelectric turbines have a start-up time on the order of a few minutes.[7]

Pumped hydro

Worldwide, pumped-storage hydroelectricity (PSH) is the largest-capacity form of active grid energy storage available, and, as of March 2012, the Electric Power Research Institute (EPRI) reports that PSH accounts for more than 99% of bulk storage capacity worldwide, representing around 127,000 MW.[8] PSH energy efficiency varies in practice between 70% and 80%,[8][9][10][11] with claims of up to 87%.[12]

At times of low electrical demand, excess generation capacity is used to pump water from a lower source into a higher reservoir. When demand grows, water is released back into a lower reservoir (or waterway or body of water) through a turbine, generating electricity. Reversible turbine-generator assemblies act as both a pump and turbine (usually a Francis turbine design). Nearly all facilities use the height difference between two water bodies. Pure pumped-storage plants shift the water between reservoirs, while the "pump-back" approach is a combination of pumped storage and conventional hydroelectric plants that use natural stream-flow.

Compressed air

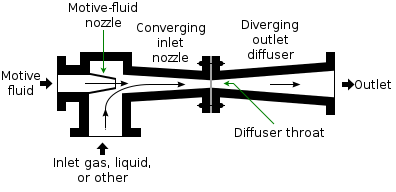

Compressed air energy storage (CAES) uses surplus energy to compress air for subsequent electricity generation.[13] Small-scale systems have long been used in such applications as propulsion of mine locomotives. The compressed air is stored in an underground reservoir, such as a salt dome.

Compressed-air energy storage (CAES) plants can bridge the gap between production volatility and load. CAES storage addresses the energy needs of consumers by effectively providing readily available energy to meet demand. Renewable energy sources like wind and solar energy vary. So at times when they provide little power, they need to be supplemented with other forms of energy to meet energy demand. Compressed-air energy storage plants can take in the surplus energy output of renewable energy sources during times of energy over-production. This stored energy can be used at a later time when demand for electricity increases or energy resource availability decreases.[14]

Compression of air creates heat; the air is warmer after compression. Expansion requires heat. If no extra heat is added, the air will be much colder after expansion. If the heat generated during compression can be stored and used during expansion, efficiency improves considerably.[15] A CAES system can deal with the heat in three ways. Air storage can be adiabatic, diabatic, or isothermal. Another approach uses compressed air to power vehicles.[16][17]

Flywheel

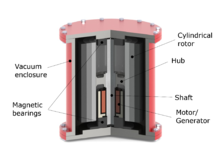

Flywheel energy storage (FES) works by accelerating a rotor (a flywheel) to a very high speed, holding energy as rotational energy. When energy is added the rotational speed of the flywheel increases, and when energy is extracted, the speed declines, due to conservation of energy.

Most FES systems use electricity to accelerate and decelerate the flywheel, but devices that directly use mechanical energy are under consideration.[18]

FES systems have rotors made of high strength carbon-fiber composites, suspended by magnetic bearings and spinning at speeds from 20,000 to over 50,000 revolutions per minute (rpm) in a vacuum enclosure.[19] Such flywheels can reach maximum speed ("charge") in a matter of minutes. The flywheel system is connected to a combination electric motor/generator.

FES systems have relatively long lifetimes (lasting decades with little or no maintenance;[19] full-cycle lifetimes quoted for flywheels range from in excess of 105, up to 107, cycles of use),[20] high specific energy (100–130 W·h/kg, or 360–500 kJ/kg)[20][21] and power density.

Solid mass gravitational

Changing the altitude of solid masses can store or release energy via an elevating system driven by an electric motor/generator. Studies suggest energy can begin to be released with as little as 1 second warning, making the method a useful supplemental feed into an electricity grid to balance load surges.[22]

Efficiencies can be as high as 85% recovery of stored energy.[23]

This can be achieved by siting the masses inside old vertical mine shafts or in specially constructed towers where the heavy weights are winched up to store energy and allowed a controlled descent to release it. At 2020 a prototype vertical store is being built in Edinburgh, Scotland [24]

Potential energy storage or gravity energy storage was under active development in 2013 in association with the California Independent System Operator.[25][26][27] It examined the movement of earth-filled hopper rail cars driven by electric locomotives from lower to higher elevations.[28]

Other proposed methods include:-

- using rails,[28][29] cranes,[23] or elevators[30] to move weights up and down;

- using high-altitude solar-powered balloon platforms supporting winches to raise and lower solid masses slung underneath them,[31]

- using winches supported by an ocean barge to take advantage of a 4 km (13,000 ft) elevation difference between the sea surface and the seabed,[32]

Thermal

Thermal energy storage (TES) is the temporary storage or removal of heat.

Sensible heat thermal

Sensible heat storage take advantage of sensible heat in a material to store energy.[33]

Seasonal thermal energy storage (STES) allows heat or cold to be used months after it was collected from waste energy or natural sources. The material can be stored in contained aquifers, clusters of boreholes in geological substrates such as sand or crystalline bedrock, in lined pits filled with gravel and water, or water-filled mines.[34] Seasonal thermal energy storage (STES) projects often have paybacks in four to six years.[35] An example is Drake Landing Solar Community in Canada, for which 97% of the year-round heat is provided by solar-thermal collectors on garage roofs, enabled by a borehole thermal energy store (BTES).[36][37][38] In Braedstrup, Denmark, the community's solar district heating system also uses STES, at a temperature of 65 °C (149 °F). A heat pump, which runs only while surplus wind power is available. It is used to raise the temperature to 80 °C (176 °F) for distribution. When wind energy is not available, a gas-fired boiler is used. Twenty percent of Braedstrup's heat is solar.[39]

Latent heat thermal (LHTES)

Latent heat thermal energy storage systems work by transferring heat to or from a material to change its phase. A phase-change is the melting, solidifying, vaporizing or liquifying. Such a material is called a phase change material (PCM). Materials used in LHTESs often have a high latent heat so that at their specific temperature, the phase change absorbs a large amount of energy, much more than sensible heat.[40]

A steam accumulator is a type of LHTES where the phase change is between liquid and gas and uses the latent heat of vaporization of water. Ice storage air conditioning systems use off-peak electricity to store cold by freezing water into ice. The stored cold in ice releases during melting process and can be used for cooling at peak hours.

Cryogenic thermal energy storage

Air can be liquefied by cooling using electricity and stored as a cryogen with existing technologies. The liquid air can then be expanded through a turbine and the energy recovered as electricity. The system was demonstrated at a pilot plant in the UK in 2012.[41] In 2019, Highview announced plans to build a 50 MW in the North of England and northern Vermont, with the proposed facility able to store five to eight hours of energy, for a 250-400 MWh storage capacity.[42]

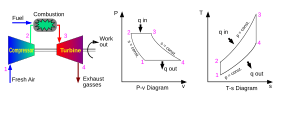

Carnot battery

Electrical energy can be stored thermally by resistive heating or heat pumps, and the stored heat can be converted back to electricity via Rankine cycle or Brayton cycle.[43] This technology has been studied to retrofit coal-fired power plants into fossil-fuel free generation systems.[44] Coal-fired boilers are replaced by high-temperature heat storage charged by excess electricity from renewable energy sources. In 2020, German Aerospace Center started to construct the world's first large-scale Carnot battery system, which has 1,000 MWh storage capacity.[45]

Electrochemical

Rechargeable battery

A rechargeable battery comprises one or more electrochemical cells. It is known as a 'secondary cell' because its electrochemical reactions are electrically reversible. Rechargeable batteries come in many shapes and sizes, ranging from button cells to megawatt grid systems.

Rechargeable batteries have lower total cost of use and environmental impact than non-rechargeable (disposable) batteries. Some rechargeable battery types are available in the same form factors as disposables. Rechargeable batteries have higher initial cost but can be recharged very cheaply and used many times.

Common rechargeable battery chemistries include:

- Lead–acid battery: Lead acid batteries hold the largest market share of electric storage products. A single cell produces about 2V when charged. In the charged state the metallic lead negative electrode and the lead sulfate positive electrode are immersed in a dilute sulfuric acid (H2SO4) electrolyte. In the discharge process electrons are pushed out of the cell as lead sulfate is formed at the negative electrode while the electrolyte is reduced to water.

- Lead-acid battery technology has been developed extensively. Upkeep requires minimal labor and its cost is low. The battery's available energy capacity is subject to a quick discharge resulting in a low life span and low energy density.[46]

- Nickel–cadmium battery (NiCd): Uses nickel oxide hydroxide and metallic cadmium as electrodes. Cadmium is a toxic element, and was banned for most uses by the European Union in 2004. Nickel–cadmium batteries have been almost completely replaced by nickel–metal hydride (NiMH) batteries.

- Nickel–metal hydride battery (NiMH): First commercial types were available in 1989.[47] These are now a common consumer and industrial type. The battery has a hydrogen-absorbing alloy for the negative electrode instead of cadmium.

- Lithium-ion battery: The choice in many consumer electronics and have one of the best energy-to-mass ratios and a very slow self-discharge when not in use.

- Lithium-ion polymer battery: These batteries are light in weight and can be made in any shape desired.

- Aluminium-sulfur battery with rock salt crystals as electrolyte: aluminium and sulfur are Earth-abundant materials and are much more cheaper than traditional Lithium.[48]

Flow battery

A flow battery works by passing a solution over a membrane where ions are exchanged to charge or discharge the cell. Cell voltage is chemically determined by the Nernst equation and ranges, in practical applications, from 1.0 V to 2.2 V. Storage capacity depends on the volume of solution. A flow battery is technically akin both to a fuel cell and an electrochemical accumulator cell. Commercial applications are for long half-cycle storage such as backup grid power.

Supercapacitor

Supercapacitors, also called electric double-layer capacitors (EDLC) or ultracapacitors, are a family of electrochemical capacitors[49] that do not have conventional solid dielectrics. Capacitance is determined by two storage principles, double-layer capacitance and pseudocapacitance.[50][51]

Supercapacitors bridge the gap between conventional capacitors and rechargeable batteries. They store the most energy per unit volume or mass (energy density) among capacitors. They support up to 10,000 farads/1.2 Volt,[52] up to 10,000 times that of electrolytic capacitors, but deliver or accept less than half as much power per unit time (power density).[49]

While supercapacitors have specific energy and energy densities that are approximately 10% of batteries, their power density is generally 10 to 100 times greater. This results in much shorter charge/discharge cycles. Also, they tolerate many more charge-discharge cycles than batteries.

Supercapacitors have many applications, including:

- Low supply current for memory backup in static random-access memory (SRAM)

- Power for cars, buses, trains, cranes and elevators, including energy recovery from braking, short-term energy storage and burst-mode power delivery

Chemical

Power to gas

Power to gas is the conversion of electricity to a gaseous fuel such as hydrogen or methane. The three commercial methods use electricity to reduce water into hydrogen and oxygen by means of electrolysis.

In the first method, hydrogen is injected into the natural gas grid or is used for transportation. The second method is to combine the hydrogen with carbon dioxide to produce methane using a methanation reaction such as the Sabatier reaction, or biological methanation, resulting in an extra energy conversion loss of 8%. The methane may then be fed into the natural gas grid. The third method uses the output gas of a wood gas generator or a biogas plant, after the biogas upgrader is mixed with the hydrogen from the electrolyzer, to upgrade the quality of the biogas.

Hydrogen

The element hydrogen can be a form of stored energy. Hydrogen can produce electricity via a hydrogen fuel cell. Green hydrogen, from electrolysis of water, is a more economical means of long-term renewable energy storage in terms of capital expenditures than pumped-storage hydroelectricity or batteries.[2][3]

At penetrations below 20% of the grid demand, renewables do not severely change the economics; but beyond about 20% of the total demand,[53] external storage becomes important. If these sources are used to make ionic hydrogen, they can be freely expanded. A 5-year community-based pilot program using wind turbines and hydrogen generators began in 2007 in the remote community of Ramea, Newfoundland and Labrador.[54] A similar project began in 2004 on Utsira, a small Norwegian island.

Energy losses involved in the hydrogen storage cycle come from the electrolysis of water, liquification or compression of the hydrogen and conversion to electricity.[55]

About 50 kW·h (180 MJ) of solar energy is required to produce a kilogram of hydrogen, so the cost of the electricity is crucial. At $0.03/kWh, a common off-peak high-voltage line rate in the United States, hydrogen costs $1.50 per kilogram for the electricity, equivalent to $1.50/gallon for gasoline. Other costs include the electrolyzer plant, hydrogen compressors or liquefaction, storage and transportation.[citation needed]

Hydrogen can also be produced from aluminum and water by stripping aluminum's naturally-occurring aluminum oxide barrier and introducing it to water. This method is beneficial because recycled aluminum cans can be used to generate hydrogen, however systems to harness this option have not been commercially developed and are much more complex than electrolysis systems.[56] Common methods to strip the oxide layer include caustic catalysts such as sodium hydroxide and alloys with gallium, mercury and other metals.[57]

Underground hydrogen storage is the practice of hydrogen storage in caverns, salt domes and depleted oil and gas fields.[58][59] Large quantities of gaseous hydrogen have been stored in caverns by Imperial Chemical Industries for many years without any difficulties.[60] The European Hyunder project indicated in 2013 that storage of wind and solar energy using underground hydrogen would require 85 caverns.[61]

Powerpaste is a magnesium and hydrogen -based fluid gel that releases hydrogen when reacting with water. It was invented, patented and is being developed by the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) of the Fraunhofer-Gesellschaft. Powerpaste is made by combining magnesium powder with hydrogen to form magnesium hydride in a process conducted at 350 °C and five to six times atmospheric pressure. An ester and a metal salt are then added to make the finished product. Fraunhofer states that they are building a production plant slated to start production in 2021, which will produce 4 tons of Powerpaste annually.[62] Fraunhofer has patented their invention in the United States and EU.[63] Fraunhofer claims that Powerpaste is able to store hydrogen energy at 10 times the energy density of a lithium battery of a similar dimension and is safe and convenient for automotive situations.[62]

Methane

Methane is the simplest hydrocarbon with the molecular formula CH4. Methane is more easily stored and transported than hydrogen. Storage and combustion infrastructure (pipelines, gasometers, power plants) are mature.

Synthetic natural gas (syngas or SNG) can be created in a multi-step process, starting with hydrogen and oxygen. Hydrogen is then reacted with carbon dioxide in a Sabatier process, producing methane and water. Methane can be stored and later used to produce electricity. The resulting water is recycled, reducing the need for water. In the electrolysis stage, oxygen is stored for methane combustion in a pure oxygen environment at an adjacent power plant, eliminating nitrogen oxides.

Methane combustion produces carbon dioxide (CO2) and water. The carbon dioxide can be recycled to boost the Sabatier process and water can be recycled for further electrolysis. Methane production, storage and combustion recycles the reaction products.

The CO2 has economic value as a component of an energy storage vector, not a cost as in carbon capture and storage.

Power to liquid

Power to liquid is similar to power to gas except that the hydrogen is converted into liquids such as methanol or ammonia. These are easier to handle than gases, and requires fewer safety precautions than hydrogen. They can be used for transportation, including aircraft, but also for industrial purposes or in the power sector.[64]

Biofuels

Various biofuels such as biodiesel, vegetable oil, alcohol fuels, or biomass can replace fossil fuels. Various chemical processes can convert the carbon and hydrogen in coal, natural gas, plant and animal biomass and organic wastes into short hydrocarbons suitable as replacements for existing hydrocarbon fuels. Examples are Fischer–Tropsch diesel, methanol, dimethyl ether and syngas. This diesel source was used extensively in World War II in Germany, which faced limited access to crude oil supplies. South Africa produces most of the country's diesel from coal for similar reasons.[65] A long term oil price above US$35/bbl may make such large scale synthetic liquid fuels economical.

Aluminum

Aluminum has been proposed as an energy store by a number of researchers. Its electrochemical equivalent (8.04 Ah/cm3) is nearly four times greater than that of lithium (2.06 Ah/cm3).[66] Energy can be extracted from aluminum by reacting it with water to generate hydrogen.[67] However, it must first be stripped of its natural oxide layer, a process which requires pulverization,[68] chemical reactions with caustic substances, or alloys.[57] The byproduct of the reaction to create hydrogen is aluminum oxide, which can be recycled into aluminum with the Hall–Héroult process, making the reaction theoretically renewable.[57] If the Hall-Heroult Process is run using solar or wind power, aluminum could be used to store the energy produced at higher efficiency than direct solar electrolysis.[69]

Boron, silicon, and zinc

Boron,[70] silicon,[71] and zinc[72] have been proposed as energy storage solutions.

Other chemical

The organic compound norbornadiene converts to quadricyclane upon exposure to light, storing solar energy as the energy of chemical bonds. A working system has been developed in Sweden as a molecular solar thermal system.[73]

Electrical methods

Capacitor

A capacitor (originally known as a 'condenser') is a passive two-terminal electrical component used to store energy electrostatically. Practical capacitors vary widely, but all contain at least two electrical conductors (plates) separated by a dielectric (i.e., insulator). A capacitor can store electric energy when disconnected from its charging circuit, so it can be used like a temporary battery, or like other types of rechargeable energy storage system.[74] Capacitors are commonly used in electronic devices to maintain power supply while batteries change. (This prevents loss of information in volatile memory.) Conventional capacitors provide less than 360 joules per kilogram, while a conventional alkaline battery has a density of 590 kJ/kg.

Capacitors store energy in an electrostatic field between their plates. Given a potential difference across the conductors (e.g., when a capacitor is attached across a battery), an electric field develops across the dielectric, causing positive charge (+Q) to collect on one plate and negative charge (-Q) to collect on the other plate. If a battery is attached to a capacitor for a sufficient amount of time, no current can flow through the capacitor. However, if an accelerating or alternating voltage is applied across the leads of the capacitor, a displacement current can flow. Besides capacitor plates, charge can also be stored in a dielectric layer.[75]

Capacitance is greater given a narrower separation between conductors and when the conductors have a larger surface area. In practice, the dielectric between the plates emits a small amount of leakage current and has an electric field strength limit, known as the breakdown voltage. However, the effect of recovery of a dielectric after a high-voltage breakdown holds promise for a new generation of self-healing capacitors.[76][77] The conductors and leads introduce undesired inductance and resistance.

Research is assessing the quantum effects of nanoscale capacitors[78] for digital quantum batteries.[79][80]

Superconducting magnetics

Superconducting magnetic energy storage (SMES) systems store energy in a magnetic field created by the flow of direct current in a superconducting coil that has been cooled to a temperature below its superconducting critical temperature. A typical SMES system includes a superconducting coil, power conditioning system and refrigerator. Once the superconducting coil is charged, the current does not decay and the magnetic energy can be stored indefinitely.[81]

The stored energy can be released to the network by discharging the coil. The associated inverter/rectifier accounts for about 2–3% energy loss in each direction. SMES loses the least amount of electricity in the energy storage process compared to other methods of storing energy. SMES systems offer round-trip efficiency greater than 95%.[82]

Due to the energy requirements of refrigeration and the cost of superconducting wire, SMES is used for short duration storage such as improving power quality. It also has applications in grid balancing.[81]

Applications

Mills

The classic application before the industrial revolution was the control of waterways to drive water mills for processing grain or powering machinery. Complex systems of reservoirs and dams were constructed to store and release water (and the potential energy it contained) when required.[83]

Homes

Home energy storage is expected to become increasingly common given the growing importance of distributed generation of renewable energies (especially photovoltaics) and the important share of energy consumption in buildings.[84] To exceed a self-sufficiency of 40% in a household equipped with photovoltaics, energy storage is needed.[84] Multiple manufacturers produce rechargeable battery systems for storing energy, generally to hold surplus energy from home solar or wind generation. Today, for home energy storage, Li-ion batteries are preferable to lead-acid ones given their similar cost but much better performance.[85]

Tesla Motors produces two models of the Tesla Powerwall. One is a 10 kWh weekly cycle version for backup applications and the other is a 7 kWh version for daily cycle applications.[86] In 2016, a limited version of the Tesla Powerpack 2 cost $398(US)/kWh to store electricity worth 12.5 cents/kWh (US average grid price) making a positive return on investment doubtful unless electricity prices are higher than 30 cents/kWh.[87]

RoseWater Energy produces two models of the "Energy & Storage System", the HUB 120[88] and SB20.[89] Both versions provide 28.8 kWh of output, enabling it to run larger houses or light commercial premises, and protecting custom installations. The system provides five key elements into one system, including providing a clean 60 Hz Sine wave, zero transfer time, industrial-grade surge protection, renewable energy grid sell-back (optional), and battery backup.[90][91]

Enphase Energy announced an integrated system that allows home users to store, monitor and manage electricity. The system stores 1.2 kWh of energy and 275W/500W power output.[92]

Storing wind or solar energy using thermal energy storage though less flexible, is considerably cheaper than batteries. A simple 52-gallon electric water heater can store roughly 12 kWh of energy for supplementing hot water or space heating.[93]

For purely financial purposes in areas where net metering is available, home generated electricity may be sold to the grid through a grid-tie inverter without the use of batteries for storage.

Grid electricity and power stations

Renewable energy

The largest source and the greatest store of renewable energy is provided by hydroelectric dams. A large reservoir behind a dam can store enough water to average the annual flow of a river between dry and wet seasons. A very large reservoir can store enough water to average the flow of a river between dry and wet years. While a hydroelectric dam does not directly store energy from intermittent sources, it does balance the grid by lowering its output and retaining its water when power is generated by solar or wind. If wind or solar generation exceeds the region's hydroelectric capacity, then some additional source of energy is needed.

Many renewable energy sources (notably solar and wind) produce variable power.[98] Storage systems can level out the imbalances between supply and demand that this causes. Electricity must be used as it is generated or converted immediately into storable forms.[99]

The main method of electrical grid storage is pumped-storage hydroelectricity. Areas of the world such as Norway, Wales, Japan and the US have used elevated geographic features for reservoirs, using electrically powered pumps to fill them. When needed, the water passes through generators and converts the gravitational potential of the falling water into electricity.[98] Pumped storage in Norway, which gets almost all its electricity from hydro, has currently a capacity of 1.4 GW but since the total installed capacity is nearly 32 GW and 75% of that is regulable, it can be expanded significantly.[100]

Some forms of storage that produce electricity include pumped-storage hydroelectric dams, rechargeable batteries, thermal storage including molten salts which can efficiently store and release very large quantities of heat energy,[101] and compressed air energy storage, flywheels, cryogenic systems and superconducting magnetic coils.

Surplus power can also be converted into methane (sabatier process) with stockage in the natural gas network.[102][103]

In 2011, the Bonneville Power Administration in Northwestern United States created an experimental program to absorb excess wind and hydro power generated at night or during stormy periods that are accompanied by high winds. Under central control, home appliances absorb surplus energy by heating ceramic bricks in special space heaters to hundreds of degrees and by boosting the temperature of modified hot water heater tanks. After charging, the appliances provide home heating and hot water as needed. The experimental system was created as a result of a severe 2010 storm that overproduced renewable energy to the extent that all conventional power sources were shut down, or in the case of a nuclear power plant, reduced to its lowest possible operating level, leaving a large area running almost completely on renewable energy.[104][105]

Another advanced method used at the former Solar Two project in the United States and the Solar Tres Power Tower in Spain uses molten salt to store thermal energy captured from the sun and then convert it and dispatch it as electrical power. The system pumps molten salt through a tower or other special conduits to be heated by the sun. Insulated tanks store the solution. Electricity is produced by turning water to steam that is fed to turbines.

Since the early 21st century batteries have been applied to utility scale load-leveling and frequency regulation capabilities.[98]

In vehicle-to-grid storage, electric vehicles that are plugged into the energy grid can deliver stored electrical energy from their batteries into the grid when needed.

Air conditioning

Thermal energy storage (TES) can be used for air conditioning.[106] It is most widely used for cooling single large buildings and/or groups of smaller buildings. Commercial air conditioning systems are the biggest contributors to peak electrical loads. In 2009, thermal storage was used in over 3,300 buildings in over 35 countries. It works by chilling material at night and using the chilled material for cooling during the hotter daytime periods.[101]

The most popular technique is ice storage, which requires less space than water and is cheaper than fuel cells or flywheels. In this application, a standard chiller runs at night to produce an ice pile. Water circulates through the pile during the day to chill water that would normally be the chiller's daytime output.

A partial storage system minimizes capital investment by running the chillers nearly 24 hours a day. At night, they produce ice for storage and during the day they chill water. Water circulating through the melting ice augments the production of chilled water. Such a system makes ice for 16 to 18 hours a day and melts ice for six hours a day. Capital expenditures are reduced because the chillers can be just 40% - 50% of the size needed for a conventional, no-storage design. Storage sufficient to store half a day's available heat is usually adequate.

A full storage system shuts off the chillers during peak load hours. Capital costs are higher, as such a system requires larger chillers and a larger ice storage system.

This ice is produced when electrical utility rates are lower.[107] Off-peak cooling systems can lower energy costs. The U.S. Green Building Council has developed the Leadership in Energy and Environmental Design (LEED) program to encourage the design of reduced-environmental impact buildings. Off-peak cooling may help toward LEED Certification.[108]

Thermal storage for heating is less common than for cooling. An example of thermal storage is storing solar heat to be used for heating at night.

Latent heat can also be stored in technical phase change materials (PCMs). These can be encapsulated in wall and ceiling panels, to moderate room temperatures.

Transport

Liquid hydrocarbon fuels are the most commonly used forms of energy storage for use in transportation, followed by a growing use of Battery Electric Vehicles and Hybrid Electric Vehicles. Other energy carriers such as hydrogen can be used to avoid producing greenhouse gases.

Public transport systems like trams and trolleybuses require electricity, but due to their variability in movement, a steady supply of electricity via renewable energy is challenging. Photovoltaic systems installed on the roofs of buildings can be used to power public transportation systems during periods in which there is increased demand for electricity and access to other forms of energy are not readily available.[109] Upcoming transitions in the transportation system also include e.g. ferries and airplanes, where electric power supply is investigated as an interesting alternative.[110]

Electronics

Capacitors are widely used in electronic circuits for blocking direct current while allowing alternating current to pass. In analog filter networks, they smooth the output of power supplies. In resonant circuits they tune radios to particular frequencies. In electric power transmission systems they stabilize voltage and power flow.[111]

Use cases

The United States Department of Energy International Energy Storage Database (IESDB), is a free-access database of energy storage projects and policies funded by the United States Department of Energy Office of Electricity and Sandia National Labs.[112]

Capacity

Storage capacity is the amount of energy extracted from an energy storage device or system; usually measured in joules or kilowatt-hours and their multiples, it may be given in number of hours of electricity production at power plant nameplate capacity; when storage is of primary type (i.e., thermal or pumped-water), output is sourced only with the power plant embedded storage system.[113][114]

Economics

The economics of energy storage strictly depends on the reserve service requested, and several uncertainty factors affect the profitability of energy storage. Therefore, not every storage method is technically and economically suitable for the storage of several MWh, and the optimal size of the energy storage is market and location dependent.[115]

Moreover, ESS are affected by several risks, e.g.:[116]

- Techno-economic risks, which are related to the specific technology;

- Market risks, which are the factors that affect the electricity supply system;

- Regulation and policy risks.

Therefore, traditional techniques based on deterministic Discounted Cash Flow (DCF) for the investment appraisal are not fully adequate to evaluate these risks and uncertainties and the investor's flexibility to deal with them. Hence, the literature recommends to assess the value of risks and uncertainties through the Real Option Analysis (ROA), which is a valuable method in uncertain contexts.[116]

The economic valuation of large-scale applications (including pumped hydro storage and compressed air) considers benefits including: curtailment avoidance, grid congestion avoidance, price arbitrage and carbon-free energy delivery.[101][117][118] In one technical assessment by the Carnegie Mellon Electricity Industry Centre, economic goals could be met using batteries if their capital cost was $30 to $50 per kilowatt-hour.[101]

A metric of energy efficiency of storage is energy storage on energy invested (ESOI), which is the amount of energy that can be stored by a technology, divided by the amount of energy required to build that technology. The higher the ESOI, the better the storage technology is energetically. For lithium-ion batteries this is around 10, and for lead acid batteries it is about 2. Other forms of storage such as pumped hydroelectric storage generally have higher ESOI, such as 210.[119]

Pumped-storage hydroelectricity is by far the largest storage technology used globally.[120] However, the usage of conventional pumped-hydro storage is limited because it requires terrain with elevation differences and also has a very high land use for relatively small power.[121] In locations without suitable natural geography, underground pumped-hydro storage could also be used.[122] High costs and limited life still make batteries a "weak substitute" for dispatchable power sources, and are unable to cover for variable renewable power gaps lasting for days, weeks or months. In grid models with high VRE share, the excessive cost of storage tends to dominate the costs of the whole grid — for example, in California alone 80% share of VRE would require 9.6 TWh of storage but 100% would require 36.3 TWh. As of 2018 the state only had 150 GWh of storage, primarily in pumped storage and a small fraction in batteries. According to another study, supplying 80% of US demand from VRE would require a smart grid covering the whole country or battery storage capable to supply the whole system for 12 hours, both at cost estimated at $2.5 trillion.[123][124] Similarly, several studies have found that relying only on VRE and energy storage would cost about 30-50% more than a comparable system that combines VRE with nuclear plants or plants with carbon capture and storage instead of energy storage.[125][126]

Research

Germany

In 2013, the German Federal government allocated €200M (approximately US$270M) for research, and another €50M to subsidize battery storage in residential rooftop solar panels, according to a representative of the German Energy Storage Association.[127]

Siemens AG commissioned a production-research plant to open in 2015 at the Zentrum für Sonnenenergie und Wasserstoff (ZSW, the German Center for Solar Energy and Hydrogen Research in the State of Baden-Württemberg), a university/industry collaboration in Stuttgart, Ulm and Widderstall, staffed by approximately 350 scientists, researchers, engineers, and technicians. The plant develops new near-production manufacturing materials and processes (NPMM&P) using a computerized Supervisory Control and Data Acquisition (SCADA) system. It aims to enable the expansion of rechargeable battery production with increased quality and lower cost.[128][129]

United States

In 2014, research and test centers opened to evaluate energy storage technologies. Among them was the Advanced Systems Test Laboratory at the University of Wisconsin at Madison in Wisconsin State, which partnered with battery manufacturer Johnson Controls.[130] The laboratory was created as part of the university's newly opened Wisconsin Energy Institute. Their goals include the evaluation of state-of-the-art and next generation electric vehicle batteries, including their use as grid supplements.[130]

The State of New York unveiled its New York Battery and Energy Storage Technology (NY-BEST) Test and Commercialization Center at Eastman Business Park in Rochester, New York, at a cost of $23 million for its almost 1,700 m2 laboratory. The center includes the Center for Future Energy Systems, a collaboration between Cornell University of Ithaca, New York and the Rensselaer Polytechnic Institute in Troy, New York. NY-BEST tests, validates and independently certifies diverse forms of energy storage intended for commercial use.[131]

On September 27, 2017, Senators Al Franken of Minnesota and Martin Heinrich of New Mexico introduced Advancing Grid Storage Act (AGSA), which would devote more than $1 billion in research, technical assistance and grants to encourage energy storage in the United States.[132]

In grid models with high VRE share, the excessive cost of storage tends to dominate the costs of the whole grid — for example, in California alone 80% share of VRE would require 9.6 TWh of storage but 100% would require 36.3 TWh. According to another study, supplying 80% of US demand from VRE would require a smart grid covering the whole country or battery storage capable to supply the whole system for 12 hours, both at cost estimated at $2.5 trillion.[123][124]

United Kingdom

In the United Kingdom, some 14 industry and government agencies allied with seven British universities in May 2014 to create the SUPERGEN Energy Storage Hub in order to assist in the coordination of energy storage technology research and development.[133][134]

See also

References

Simple waterwheels were used in the Balkans of Europe in 100 B.C.E for powering flour mills. Elaborate Irrigation systems had been built In Egypt and Mesopotamia a thousand years before that, and it is very likely that these systems contained simple waterwheels. Waterwheels powered by a stream running underneath were common in the Roman Empire during the third and fourth centuries C.E. After the fall of the Western Roman Empire, water technology advanced further in the Middle East than in Europe, but waterwheels were commonly used to harness water as a source of power in Europe during the Middle Ages. The Doomsday Book of 1086 C.E. lists 5624 water powered mills in the southern half of England. The designs of more efficient waterwheels were brought back to Europe from the Middle East by the Crusaders and were used for grinding grain and for powering furnace bellows.

- New SUPERGEN Hub to set UK's energy storage course Archived May 8, 2014, at the Wayback Machine, ECNMag.com website, May 2, 2014.

Further reading

Journals and papers

- Chen, Haisheng; Thang Ngoc Cong; Wei Yang; Chunqing Tan; Yongliang Li; Yulong Ding. Progress in electrical energy storage system: A critical review, Progress in Natural Science, accepted July 2, 2008, published in Vol. 19, 2009, pp. 291–312, doi: 10.1016/j.pnsc.2008.07.014. Sourced from the National Natural Science Foundation of China and the Chinese Academy of Sciences. Published by Elsevier and Science in China Press. Synopsis: a review of electrical energy storage technologies for stationary applications. Retrieved from ac.els-cdn.com on May 13, 2014. (PDF)

- Corum, Lyn. The New Core Technology: Energy storage is part of the smart grid evolution, The Journal of Energy Efficiency and Reliability, December 31, 2009. Discusses: Anaheim Public Utilities Department, lithium ion energy storage, iCel Systems, Beacon Power, Electric Power Research Institute (EPRI), ICEL, Self Generation Incentive Program, ICE Energy, vanadium redox flow, lithium Ion, regenerative fuel cell, ZBB, VRB, lead acid, CAES, and Thermal Energy Storage. (PDF)

- de Oliveira e Silva, G.; Hendrick, P. (2016). "Lead-acid batteries coupled with photovoltaics for increased electricity self-sufficiency in households". Applied Energy. 178: 856–867. doi:10.1016/j.apenergy.2016.06.003.

- Whittingham, M. Stanley. History, Evolution, and Future Status of Energy Storage, Proceedings of the IEEE, manuscript accepted February 20, 2012, date of publication April 16, 2012; date of current version May 10, 2012, published in Proceedings of the IEEE, Vol. 100, May 13, 2012, 0018–9219, pp. 1518–1534, doi: 10.1109/JPROC.2012.219017. Retrieved from ieeexplore.ieee.org May 13, 2014. Synopsis: A discussion of the important aspects of energy storage including emerging battery technologies and the importance of storage systems in key application areas, including electronic devices, transportation, and the utility grid. (PDF)

Books

- GA Mansoori, N Enayati, LB Agyarko (2016), Energy: Sources, Utilization, Legislation, Sustainability, Illinois as Model State, World Sci. Pub. Co., ISBN 978-981-4704-00-7

- Díaz-González, Franscisco (2016). Energy storage in power systems. United Kingdom: John Wiley & Sons. ISBN 9781118971321.

External links

- U.S. Dept of Energy - Energy Storage Systems Government research center on energy storage technology.

- U.S. Dept of Energy - International Energy Storage Database Archived November 13, 2013, at the Wayback Machine The DOE International Energy Storage Database provides free, up-to-date information on grid-connected energy storage projects and relevant state and federal policies.

- IEEE Special Issue on Massive Energy Storage

- IEA-ECES - International Energy Agency - Energy Conservation through Energy Conservation programme.

- Energy Information Administration Glossary

- Energy Storage Project Regeneration.

https://en.wikipedia.org/wiki/Energy_storage

In an electrical power distribution system, a ring main unit (RMU) is a factory assembled, metal enclosed set of switchgear used at the load connection points of a ring-type distribution network. It includes in one unit two switches that can connect the load to either or both main conductors, and a fusible switch or circuit breaker and switch that feed a distribution transformer. [1] The metal enclosed unit connects to the transformer either through a bus throat of standardized dimensions, or else through cables and is usually installed outdoors. Ring main cables enter and leave the cabinet. This type of switchgear is used for medium-voltage power distribution, from 7200 volts to about 36000 volts.

The ring main unit was introduced in the United Kingdom and is now widely used in other countries. In North American distribution practice, often the equivalent of a ring main unit is built into a pad-mounted transformer which integrates switches and transformer into a single cabinet.

Categories

Ring main units can be characterized by their type of insulation: air, oil or gas. The switch used to isolate the transformer can be a fusible switch, or may be a circuit breaker using vacuum or gas-insulated interrupters. The unit may also include protective relays to operate the circuit breaker on a fault.

See also

https://en.wikipedia.org/wiki/Ring_main_unit

https://en.wikipedia.org/wiki/Flywheel_energy_storage

https://en.wikipedia.org/wiki/Storage_heater

https://en.wikipedia.org/wiki/Molten_salt_heat_storage

https://en.wikipedia.org/wiki/Steam_accumulator

https://en.wikipedia.org/wiki/Power-to-gas

https://en.wikipedia.org/wiki/Reversible_solid_oxide_cell

Open-circuit voltage (abbreviated as OCV or VOC) is the difference of electrical potential between two terminals of an electronic device when disconnected from any circuit.[1] There is no external load connected. No external electric current flows between the terminals. Alternatively, the open-circuit voltage may be thought of as the voltage that must be applied to a solar cell or a battery to stop the current. It is sometimes given the symbol Voc. In network analysis this voltage is also known as the Thévenin voltage.

The open-circuit voltages of batteries and solar cells are often quoted under particular conditions (state-of-charge, illumination, temperature, etc.).

The potential difference mentioned for batteries and cells is usually the open-circuit voltage.

The value of the open-circuit voltage of a transducer equals its electromotive force (emf), which is the maximum potential difference it can produce when not providing current.

https://en.wikipedia.org/wiki/Open-circuit_voltage

https://en.wikipedia.org/wiki/Overpotential

https://en.wikipedia.org/wiki/Short_circuit

https://en.wikipedia.org/wiki/Electromotive_force

The reactions taking place on the oxygen electrode are the same considered for the hydrogen/steam case. Even if characterized by much slower kinetics with respect to the one involving hydrogen and steam, the direct electro-oxidation of carbon monoxide (forward reaction) or the direct electro-reduction of carbon dioxide (backward reaction) can be considered as well:

The thermoneutral voltage of the electrolysis is equal to 1.48 V.

One useful way to depict the cycling between SOFC and SOEC mode of the rSOC operation with carbonaceous reactants is the C-H-O ternary diagram.[6] Each point in the diagram represents a gas mixture with a different number of carbon, hydrogen or oxygen atoms. When dealing with the operation on reversible solid oxide cells, three distinct regions can be distinguished in the graph. For different operating conditions (i.e., different temperature and pressure), distinct boundary lines between these regions can be drawn. The three regions are:

- the carbon deposition region: gas mixtures lying in this region are characterized by compositions that are prone to carbon deposition on the fuel electrode;

- the fully oxidized region: this region is characterized by gas mixtures that are fully oxidized, hence they cannot be used as fuels in the rSOC;

- the operating region: this region is characterized by gas mixtures that are suitable for the rSOC operation.

In the operating region, the fuel mixture and the exhaust mixture can be depicted. These two points are connected by a line which runs through points characterized by a constant H/C ratio. In fact, during the rSOC operation in both modalities, the gases on the fuel electrode exchange with the oxygen electrode only oxygen atoms, while hydrogen and carbon are confined inside the fuel electrode. During the SOFC operation, the composition of the gas in the fuel electrode moves towards the boundary line of the fully oxidized region, increasing its oxygen content. During SOEC operation, on the other hand, the gas mixture evolves away from the fully oxidized region towards the carbon deposition region, while reducing its oxygen content.

https://en.wikipedia.org/wiki/Reversible_solid_oxide_cell

The gas may be used as chemical feedstock, or converted back into electricity using conventional generators such as gas turbines.[6] Power-to-gas allows energy from electricity to be stored and transported in the form of compressed gas, often using existing infrastructure for long-term transport and storage of natural gas. P2G is often considered the most promising technology for seasonal renewable energy storage.[7][8]

https://en.wikipedia.org/wiki/Power-to-gas

https://en.wikipedia.org/wiki/Pumped-storage_hydroelectricity

https://en.wikipedia.org/wiki/LNG_carrier

https://en.wikipedia.org/wiki/Pipeline_transport#Oil_and_natural_gas

https://en.wikipedia.org/wiki/Pipeline_transport#Oil_and_natural_gas

Construction and operation

Oil pipelines are made from steel or plastic tubes with inner diameter typically from 4 to 48 inches (100 to 1,220 mm). Most pipelines are typically buried at a depth of about 3 to 6 feet (0.91 to 1.83 m). To protect pipes from impact, abrasion, and corrosion, a variety of methods are used. These can include wood lagging (wood slats), concrete coating, rockshield, high-density polyethylene, imported sand padding, sacrificial cathodes and padding machines.[13]

Crude oil contains varying amounts of paraffin wax and in colder climates wax buildup may occur within a pipeline. Often these pipelines are inspected and cleaned using pigging, the practice of using devices known as "pigs" to perform various maintenance operations on a pipeline. The devices are also known as "scrapers" or "Go-devils". "Smart pigs" (also known as "intelligent" or "intelligence" pigs) are used to detect anomalies in the pipe such as dents, metal loss caused by corrosion, cracking or other mechanical damage.[14] These devices are launched from pig-launcher stations and travel through the pipeline to be received at any other station down-stream, either cleaning wax deposits and material that may have accumulated inside the line or inspecting and recording the condition of the line.

For natural gas, pipelines are constructed of carbon steel and vary in size from 2 to 60 inches (51 to 1,524 mm) in diameter, depending on the type of pipeline. The gas is pressurized by compressor stations and is odorless unless mixed with a mercaptan odorant where required by a regulating authority.

Ammonia

A major ammonia pipeline is the Ukrainian Transammiak line connecting the TogliattiAzot facility in Russia to the exporting Black Sea-port of Odesa.

Alcohol fuels

Pipelines have been used for transportation of ethanol in Brazil, and there are several ethanol pipeline projects in Brazil and the United States.[15] The main problems related to the transport of ethanol by pipeline are its corrosive nature and tendency to absorb water and impurities in pipelines, which are not problems with oil and natural gas.[15][16] Insufficient volumes and cost-effectiveness are other considerations limiting construction of ethanol pipelines.[16][17] In the US minimal amounts of ethanol are transported by pipeline. Most ethanol is shipped by rail, the main alternatives being truck and barge. Delivering ethanol by pipeline is the most desirable option, but ethanol's affinity for water and solvent properties require the use of a dedicated pipeline, or significant cleanup of existing pipelines.

Coal and ore

Slurry pipelines are sometimes used to transport coal or ore from mines. The material to be transported is closely mixed with water before being introduced to the pipeline; at the far end, the material must be dried. One example is a 525-kilometre (326 mi) slurry pipeline which is planned to transport iron ore from the Minas-Rio mine (producing 26.5 million tonnes per year) to the Port of Açu in Brazil.[18] An existing example is the 85-kilometre (53 mi) Savage River Slurry pipeline in Tasmania, Australia, possibly the world's first when it was built in 1967. It includes a 366-metre (1,201 ft) bridge span at 167 metres (548 ft) above the Savage River.[19][20]

Hydrogen

Hydrogen pipeline transport is a transportation of hydrogen through a pipe as part of the hydrogen infrastructure. Hydrogen pipeline transport is used to connect the point of hydrogen production or delivery of hydrogen with the point of demand, with transport costs similar to CNG,[21] the technology is proven.[22] Most hydrogen is produced at the place of demand with every 50 to 100 miles (160 km) an industrial production facility.[23] The 1938 Rhine-Ruhr 240-kilometre (150 mi) hydrogen pipeline is still in operation.[24] As of 2004, there are 900 miles (1,400 km) of low pressure hydrogen pipelines in the US and 930 miles (1,500 km) in Europe.

Water

Two millennia ago, the ancient Romans made use of large aqueducts to transport water from higher elevations by building the aqueducts in graduated segments that allowed gravity to push the water along until it reached its destination. Hundreds of these were built throughout Europe and elsewhere, and along with flour mills were considered the lifeline of the Roman Empire. The ancient Chinese also made use of channels and pipe systems for public works. The famous Han Dynasty court eunuch Zhang Rang (d. 189 AD) once ordered the engineer Bi Lan to construct a series of square-pallet chain pumps outside the capital city of Luoyang.[25] These chain pumps serviced the imperial palaces and living quarters of the capital city as the water lifted by the chain pumps was brought in by a stoneware pipe system.[25][26]

Pipelines are useful for transporting water for drinking or irrigation over long distances when it needs to move over hills, or where canals or channels are poor choices due to considerations of evaporation, pollution, or environmental impact.

The 530 km (330 mi) Goldfields Water Supply Scheme in Western Australia using 750 mm (30 inch) pipe and completed in 1903 was the largest water supply scheme of its time.[27][28]

Examples of significant water pipelines in South Australia are the Morgan-Whyalla pipeline (completed 1944) and Mannum-Adelaide pipeline (completed 1955) pipelines, both part of the larger Snowy Mountains scheme.[29]

There are two Los Angeles, California aqueducts, the Owens Valley aqueduct (completed 1913) and the Second Los Angeles Aqueduct (completed 1970) which also include extensive use of pipelines.

The Great Manmade River of Libya supplies 3,680,000 cubic metres (4,810,000 cu yd) of water each day to Tripoli, Benghazi, Sirte, and several other cities in Libya. The pipeline is over 2,800 kilometres (1,700 mi) long, and is connected to wells tapping an aquifer over 500 metres (1,600 ft) underground.[30]

Other systems

District heating

District heating or teleheating systems consist of a network of insulated feed and return pipes which transport heated water, pressurized hot water, or sometimes steam to the customer. While steam is hottest and may be used in industrial processes due to its higher temperature, it is less efficient to produce and transport due to greater heat losses. Heat transfer oils are generally not used for economic and ecological reasons. The typical annual loss of thermal energy through distribution is around 10%, as seen in Norway's district heating network.[32]

District heating pipelines are normally installed underground, with some exceptions. Within the system, heat storage may be installed to even out peak load demands. Heat is transferred into the central heating of the dwellings through heat exchangers at heat substations, without mixing of the fluids in either system.

Beer

Bars in the Veltins-Arena, a major football ground in Gelsenkirchen, Germany, are interconnected by a 5-kilometre (3.1 mi) long beer pipeline. In Randers city in Denmark, the so-called Thor Beer pipeline was operated. Originally, copper pipes ran directly from the brewery, but when the brewery moved out of the city in the 1990s, Thor Beer replaced it with a giant tank.

A three-kilometer beer pipeline was completed in Bruges, Belgium in September 2016 to reduce truck traffic on the city streets.[33]

Brine

The village of Hallstatt in Austria, which is known for its long history of salt mining, claims to contain "the oldest industrial pipeline in the world", dating back to 1595.[34] It was constructed from 13,000 hollowed-out tree trunks to transport brine 40 kilometres (25 mi) from Hallstatt to Ebensee.[35]

https://en.wikipedia.org/wiki/Pipeline_transport#Oil_and_natural_gas

Marine pipelines

In places, a pipeline may have to cross water expanses, such as small seas, straits and rivers.[37] In many instances, they lie entirely on the seabed. These pipelines are referred to as "marine" pipelines (also, "submarine" or "offshore" pipelines). They are used primarily to carry oil or gas, but transportation of water is also important.[37] In offshore projects, a distinction is made between a "flowline" and a pipeline.[37][38][39] The former is an intrafield pipeline, in the sense that it is used to connect subsea wellheads, manifolds and the platform within a particular development field. The latter, sometimes referred to as an "export pipeline", is used to bring the resource to shore.[38] The construction and maintenance of marine pipelines imply logistical challenges that are different from those onland, mainly because of wave and current dynamics, along with other geohazards. In Nigeria oil pipelines get bored by thieves, in 2022, during the Russian-Ukrainian war, the submarine natural gas pipelines Nord Stream I and II got blasted.

Functions

In general, pipelines can be classified in three categories depending on purpose:

- Gathering pipelines

- Group of smaller interconnected pipelines forming complex networks with the purpose of bringing crude oil or natural gas from several nearby wells to a treatment plant or processing facility. In this group, pipelines are usually short- a couple hundred metres- and with small diameters. Sub-sea pipelines for collecting product from deep water production platforms are also considered gathering systems.

- Transportation pipelines

- Mainly long pipes with large diameters, moving products (oil, gas, refined products) between cities, countries and even continents. These transportation networks include several compressor stations in gas lines or pump stations for crude and multi-products pipelines.

- Distribution pipelines

- Composed of several interconnected pipelines with small diameters, used to take the products to the final consumer. Feeder lines to distribute gas to homes and businesses downstream. Pipelines at terminals for distributing products to tanks and storage facilities are included in this groups.

https://en.wikipedia.org/wiki/Pipeline_transport#Oil_and_natural_gas

Operation

Field devices are instrumentation, data gathering units and communication systems. The field instrumentation includes flow, pressure, and temperature gauges/transmitters, and other devices to measure the relevant data required. These instruments are installed along the pipeline on some specific locations, such as injection or delivery stations, pump stations (liquid pipelines) or compressor stations (gas pipelines), and block valve stations.

The information measured by these field instruments is then gathered in local remote terminal units (RTU) that transfer the field data to a central location in real time using communication systems, such as satellite channels, microwave links, or cellular phone connections.

Pipelines are controlled and operated remotely, from what is usually known as the "Main Control Room". In this center, all the data related to field measurement is consolidated in one central database. The data is received from multiple RTUs along the pipeline. It is common to find RTUs installed at every station along the pipeline.

The SCADA system at the Main Control Room receives all the field data and presents it to the pipeline operator through a set of screens or Human Machine Interface, showing the operational conditions of the pipeline. The operator can monitor the hydraulic conditions of the line, as well as send operational commands (open/close valves, turn on/off compressors or pumps, change setpoints, etc.) through the SCADA system to the field.

To optimize and secure the operation of these assets, some pipeline companies are using what is called "Advanced Pipeline Applications", which are software tools installed on top of the SCADA system, that provide extended functionality to perform leak detection, leak location, batch tracking (liquid lines), pig tracking, composition tracking, predictive modeling, look ahead modeling, and operator training.

https://en.wikipedia.org/wiki/Pipeline_transport#Oil_and_natural_gas

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery.

https://en.wikipedia.org/wiki/SCADA#Human_Machine_Interface

A geologic hazard or geohazard is an adverse geologic condition capable of causing widespread damage or loss of property and life.[1] These hazards are geological and environmental conditions and involve long-term or short-term geological processes. Geohazards can be relatively small features, but they can also attain huge dimensions (e.g., submarine or surface landslide) and affect local and regional socio-economics to a large extent (e.g., tsunamis).

Sometimes the hazard is instigated by the careless location of developments or construction in which the conditions were not taken into account. Human activities, such as drilling through overpressured zones, could result in significant risk, and as such mitigation and prevention are paramount, through improved understanding of geohazards, their preconditions, causes and implications. In other cases, particularly in montane regions, natural processes can cause catalytic events of a complex nature, such as an avalanche hitting a lake and causing a debris flow, with consequences potentially hundreds of miles away, or creating a lahar by volcanism.

Marine geohazards in particular constitute a fast-growing sector of research as they involve seismic, tectonic, volcanic processes now occurring at higher frequency, and often resulting in coastal sub-marine avalanches or devastating tsunamis in some of the most densely populated areas of the world [2] [3]

Such impacts on vulnerable coastal populations, coastal infrastructures, offshore exploration platforms, obviously call for a higher level of preparedness and mitigation. [4][5]

Speed of development

Sudden phenomena

Sudden phenomena include:

- avalanches (snow or rock) and its runout

- earthquakes and earthquake-triggered phenomena such as tsunamis

- forest fires (espec. in Mediterranean areas) leading to deforestation

- geomagnetic storms[6]

- gulls (chasms) associated with cambering of valley sides

- ice jams (Eisstoß) on rivers or glacial lake outburst floods below a glacier

- landslide (displacement of earth materials on a slope or hillside)

- mudflows (avalanche-like muddy flow of soft/wet soil and sediment materials, narrow landslides)

- pyroclastic flows

- rockfalls, rock slides, (rock avalanche) and debris flows

- torrents (flash floods, rapid floods or heavy current creeks with irregular course)

- liquefaction (settlement of the ground in areas underlain by loose saturated sand/silt during an earthquake event)

- volcanic eruptions, lahars and ash falls.

Slow phenomena

Gradual or slow phenomena include:

- alluvial fans (e.g. at the exit of canyons or side valleys)

- caldera development (volcanoes)

- geyser deposits

- ground settlement due to consolidation of compressible soils or due to collapseable soils (see also compaction)

- ground subsidence, sags and sinkholes

- sand dune migration

- shoreline and stream erosion

- thermal springs

Evaluation and mitigation

Geologic hazards are typically evaluated by engineering geologists who are educated and trained in interpretation of landforms and earth process, earth-structure interaction, and in geologic hazard mitigation. The engineering geologist provides recommendations and designs to mitigate for geologic hazards. Trained hazard mitigation planners also assist local communities to identify strategies for mitigating the effects of such hazards and developing plans to implement these measures. Mitigation can include a variety of measures:

- Geologic hazards may be avoided by relocation. Publicly available databases, via searchable platforms,[7] can help people evaluate hazards in locations of interest.

- The stability of sloping earth can be improved by the construction of retaining walls, which may use techniques such as slurry walls, shear pins, tiebacks, soil nails or soil anchors. Larger projects may use gabions and other forms of earth buttress.

- Shorelines and streams are protected against scour and erosion using revetments and riprap.

- The soil or rock itself may be improved by means such as dynamic compaction, injection of grout or concrete, and mechanically stabilized earth.

- Additional mitigation methods include deep foundations, tunnels, surface and subdrain systems, and other measures.

- Planning measures include regulations prohibiting development near hazard-prone areas and adoption of building codes.

In paleohistory

Eleven distinct flood basalt episodes occurred in the past 250 million years, resulting in large volcanic provinces, creating lava plateaus and mountain ranges on Earth.[8] Large igneous provinces have been connected to five mass extinction events. The timing of six out of eleven known provinces coincide with periods of global warming and marine anoxia/dysoxia. Thus, suggesting that volcanic CO2 emissions can force an important effect on the climate system.[9]

Known hazards

- 2004 Indian Ocean earthquake and tsunami

- 2008 Sichuan earthquake

- 2011 Tōhoku earthquake and tsunami

- The Barrier (located in Garibaldi Provincial Park)

- Usoi Dam a natural landslide dam

Eisstoß Feb.2006 Vienna, Austria (Donauinsel)

Glacier just above Grindelwald, Switzerland

Soil liquefaction during the 1964 Niigata earthquake

See also

References

- P.B. Wignall (2001). "Large igneous provinces and mass extinctions". Earth-Science Reviews. 53 (1–2): 1–33. Bibcode:2001ESRv...53....1W. doi:10.1016/S0012-8252(00)00037-4.

External links

Media related to Geological hazards at Wikimedia Commons

Media related to Geological hazards at Wikimedia Commons- International Centre for Geohazards (ICG)

https://en.wikipedia.org/wiki/Geological_hazard

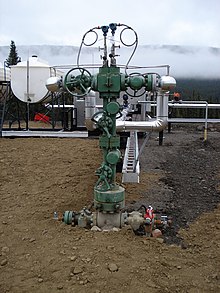

A wellhead is the component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment.

The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the hole sections to the surface pressure control equipment.[1]

While drilling the oil well, surface pressure control is provided by a blowout preventer (BOP). If the pressure is not contained during drilling operations by the column of drilling fluid, casings, wellhead, and BOP, a well blowout could occur.

When the well has been drilled, it is completed to provide an interface with the reservoir rock and a tubular conduit for the well fluids. The surface pressure control is provided by a Christmas tree, which is installed on top of the wellhead, with isolation valves and choke equipment to control the flow of well fluids during production.

Wellheads are typically welded onto the first string of casing, which has been cemented in place during drilling operations, to form an integral structure of the well. In exploration wells that are later abandoned, the wellhead may be recovered for refurbishment and re-use.

Offshore, where a wellhead is located on the production platform it is called a surface wellhead, and if located beneath the water then it is referred to as a subsea wellhead or mudline wellhead.[2][3][4][5]

Components

The primary components of a wellhead system are:

- casing head

- casing spools

- casing hangers

- choke manifold

- packoffs (isolation) seals

- test plugs

- mudline suspension systems

- tubing heads

- tubing hangers

- tubing head adapter

Functions

A wellhead serves numerous functions, some of which are:

- Provide a means of casing suspension. (Casing is the permanently installed pipe used to line the well hole for pressure containment and collapse prevention during the drilling phase).

- Provides a means of tubing suspension. (Tubing is removable pipe installed in the well through which well fluids pass).

- Provides a means of pressure sealing and isolation between casing at surface when many casing strings are used.

- Provides pressure monitoring and pumping access to annuli between the different casing/tubing strings.

- Provides a means of attaching a blowout preventer during drilling.

- Provides a means of attaching a Christmas tree for production operations.

- Provides a reliable means of well access.

- Provides a means of attaching a well pump,

Design specification

The oil industry specifications for wellhead systems (materials, dimensions, test procedures and pressure ratings etc.) are :

- API 6A, 20th Edition, October 2010; Specification for Wellhead and Christmas Tree Equipment

- ISO 10423:2009 Wellhead and Christmas Tree Equipment

In general well heads are five nominal ratings of wellheads: 2, 3, 5, 10 and 15 (x1000) psi working pressure. They have an operating temperature range of -50 to +250 degrees Fahrenheit. They are used in conjunction with ring type seal gaskets.

In general the yield strength of the materials range from 36000 to 75000 psi.

See also

- Puteal — Water well head

- Pumpjack

- American Petroleum Institute

- Drilling rig (petroleum)

References

External links

https://en.wikipedia.org/wiki/Wellhead

A puteal (Latin: from puteus (well) — plural: putealia[1]) is a classical wellhead built around a water well's access opening.

Description

The enclosure keeps people from falling down a well otherwise open at grade level.[2] When equipped with a cast iron lid, as traditionally in the public squares, or campos, of Venice, Italy, the citizens and water supply were protected.[1]

Putealia were used as an accessible point of water distribution, and as an aesthetic architectural element. Locations included public town squares and private courtyards.[1] They were often found in atriums, where they gave access to the water cistern fed by the impluvium.

Classical putealia

The classical puteal is made of carved stone, often marble in Europe. They are frequently decorated with bas-reliefs of classical Greek and Roman themes around their outer faces. An Ancient Roman one was in the Puteal Scribonianum structure in the Roman Forum, nothing remains.

The term is also used for circular classical remains (spolia) recycled after antiquity into wellheads, such as the Guildford Puteal at the British Museum.

See also

- Bidental

- Fontus (Fons) — the ancient Roman god of fountains and wellheads

- Wishing well

References

- John Weale, Rudimentary Dictionary of Terms Used in Architecture, Civil, Architecture, Naval, Building and Construction, Early and Ecclesiastical Art, Engineering, Civil, Engineering, Mechanical, Fine Art, Mining, Sur-veying, Etc., to Which Are Added Explanatory Observations on Numerous Subjects Connected with Practical Art and Science. (London: J. Weale, 1849), pg. 364.

https://en.wikipedia.org/wiki/Puteal

A pumpjack is the overground drive for a reciprocating piston pump in an oil well.[1]

https://en.wikipedia.org/wiki/Pumpjack

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals but could be used to pump water to supplement the flow for a waterwheel powering a mill.