Laser-powered phosphor display (LPD) is a large-format display technology similar to the cathode ray tube (CRT). Prysm, Inc., a video wall designer and manufacturer in Silicon Valley, California, invented and patented[1] the LPD technology.[2][3] The key components of the LPD technology are its TD2 tiles, its image processor, and its backing frame that supports LPD tile arrays.[4] The company unveiled the LPD in January 2010.[4][5][6]

https://en.wikipedia.org/wiki/Laser-powered_phosphor_display

A surface-conduction electron-emitter display (SED) is a display technology for flat panel displays developed by a number of companies. SEDs use nanoscopic-scale electron emitters to energize colored phosphors and produce an image. In a general sense, a SED consists of a matrix of tiny cathode-ray tubes, each "tube" forming a single sub-pixel on the screen, grouped in threes to form red-green-blue (RGB) pixels. SEDs combine the advantages of CRTs, namely their high contrast ratios, wide viewing angles, and very fast response times, with the packaging advantages of LCD and other flat panel displays. They also use much less power than an LCD television of the same size.

After considerable time and effort in the early and mid-2000s, SED efforts started winding down in 2009 as LCD became the dominant technology. In August 2010, Canon announced they were shutting down their joint effort to develop SEDs commercially, signaling the end of development efforts.[1] SEDs are closely related to another developing display technology, the field emission display, or FED, differing primarily in the details of the electron emitters. Sony, the main backer of FED, has similarly backed off from their development efforts.[2]

https://en.wikipedia.org/wiki/Surface-conduction_electron-emitter_display

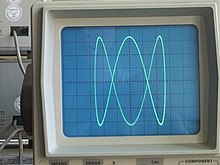

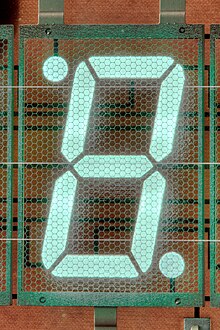

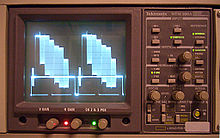

A cathode-ray tube (CRT) is a vacuum tube containing one or more electron guns, which emit electron beams that are manipulated to display images on a phosphorescent screen.[2] The images may represent electrical waveforms (oscilloscope), pictures (television set, computer monitor), radar targets, or other phenomena. A CRT on a television set is commonly called a picture tube. CRTs have also been used as memory devices, in which case the screen is not intended to be visible to an observer. The term cathode ray was used to describe electron beams when they were first discovered, before it was understood that what was emitted from the cathode was a beam of electrons.

In CRT television sets and computer monitors, the entire front area of the tube is scanned repeatedly and systematically in a fixed pattern called a raster. In color devices, an image is produced by controlling the intensity of each of three electron beams, one for each additive primary color (red, green, and blue) with a video signal as a reference.[3] In modern CRT monitors and televisions the beams are bent by magnetic deflection, using a deflection yoke. Electrostatic deflection is commonly used in oscilloscopes.[3]

A CRT is a glass envelope which is deep (i.e., long from front screen face to rear end), heavy, and fragile. The interior is evacuated to 0.01 pascals (1×10−7 atm)[4] to 0.1 micropascals (1×10−12 atm) or less,[5] to facilitate the free flight of electrons from the gun(s) to the tube's face without scattering due to collisions with air molecules. As such, handling a CRT carries the risk of violent implosion that can hurl glass at great velocity. The face is typically made of thick lead glass or special barium-strontium glass to be shatter-resistant and to block most X-ray emissions. CRTs make up most of the weight of CRT TVs and computer monitors.[6][7]

Since the mid-late 2000's, CRTs have been superseded by flat-panel display technologies such as LCD, plasma display, and OLED displays which are cheaper to manufacture and run, as well as significantly lighter and less bulky. Flat-panel displays can also be made in very large sizes whereas 40 in (100 cm) to 45 in (110 cm)[8] was about the largest size of a CRT.[9]

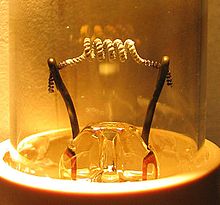

A CRT works by electrically heating a tungsten coil[10] which in turn heats a cathode in the rear of the CRT, causing it to emit electrons which are modulated and focused by electrodes. The electrons are steered by deflection coils or plates, and an anode accelerates them towards the phosphor-coated screen, which generates light when hit by the electrons.[11][12][13]

History

Discoveries

Cathode rays were discovered by Julius Plücker and Johann Wilhelm Hittorf.[14] Hittorf observed that some unknown rays were emitted from the cathode (negative electrode) which could cast shadows on the glowing wall of the tube, indicating the rays were traveling in straight lines. In 1890, Arthur Schuster demonstrated cathode rays could be deflected by electric fields, and William Crookes showed they could be deflected by magnetic fields. In 1897, J. J. Thomson succeeded in measuring the charge-mass-ratio of cathode rays, showing that they consisted of negatively charged particles smaller than atoms, the first "subatomic particles", which had already been named electrons by Irish physicist George Johnstone Stoney in 1891. The earliest version of the CRT was known as the "Braun tube", invented by the German physicist Ferdinand Braun in 1897.[15] It was a cold-cathode diode, a modification of the Crookes tube with a phosphor-coated screen. Braun was the first to conceive the use of a CRT as a display device.[16]

In 1908, Alan Archibald Campbell-Swinton, fellow of the Royal Society (UK), published a letter in the scientific journal Nature, in which he described how "distant electric vision" could be achieved by using a cathode-ray tube (or "Braun" tube) as both a transmitting and receiving device.[17] He expanded on his vision in a speech given in London in 1911 and reported in The Times[18] and the Journal of the Röntgen Society.[19][20]

The first cathode-ray tube to use a hot cathode was developed by John Bertrand Johnson (who gave his name to the term Johnson noise) and Harry Weiner Weinhart of Western Electric, and became a commercial product in 1922.[21] The introduction of hot cathodes allowed for lower acceleration anode voltages and higher electron beam currents, since the anode now only accelerated the electrons emitted by the hot cathode, and no longer had to have a very high voltage to induce electron emission from the cold cathode.[22]

Development

In 1926, Kenjiro Takayanagi demonstrated a CRT television receiver with a mechanical video camera that received images with a 40-line resolution.[23] By 1927, he improved the resolution to 100 lines, which was unrivaled until 1931.[24] By 1928, he was the first to transmit human faces in half-tones on a CRT display.[25] In 1927, Philo Farnsworth created a television prototype.[26][27][28][29][30] The CRT was named in 1929 by inventor Vladimir K. Zworykin.[25]: 84 RCA was granted a trademark for the term (for its cathode-ray tube) in 1932; it voluntarily released the term to the public domain in 1950.[31]

In the 1930s, Allen B. DuMont made the first CRTs to last 1,000 hours of use, which was one of the factors that led to the widespread adoption of television.[32]

The first commercially made electronic television sets with cathode-ray tubes were manufactured by Telefunken in Germany in 1934.[33][34]

In 1947, the cathode-ray tube amusement device, the earliest known interactive electronic game as well as the first to incorporate a cathode-ray tube screen, was created.[35]

From 1949 to the early 1960s, there was a shift from circular CRTs to rectangular CRTs, although the first rectangular CRTs were made in 1938 by Telefunken.[36][22][37][38][39][40] While circular CRTs were the norm, European TV sets often blocked portions of the screen to make it appear somewhat rectangular while American sets often left the entire front of the CRT exposed or only blocked the upper and lower portions of the CRT.[41][42]

In 1954, RCA produced some of the first color CRTs, the 15GP22 CRTs used in the CT-100,[43] the first color TV set to be mass-produced.[44] The first rectangular color CRTs were also made in 1954.[45][46] However, the first rectangular color CRTs to be offered to the public were made in 1963. One of the challenges that had to be solved to produce the rectangular color CRT was convergence at the corners of the CRT.[39][38] In 1965, brighter rare earth phosphors began replacing dimmer and cadmium-containing red and green phosphors. Eventually blue phosphors were replaced as well.[47][48][49][50][51][52]

The size of CRTs increased over time, from 20 inches in 1938,[53] to 21 inches in 1955,[54][55] 35 inches by 1985,[56] and 43 inches by 1989.[57] However, experimental 31 inch CRTs were made as far back as 1938.[58]

In 1960, the Aiken tube was invented. It was a CRT in a flat-panel display format with a single electron gun.[59][60] Deflection was electrostatic and magnetic, but due to patent problems, it was never put into production. It was also envisioned as a head-up display in aircraft.[61] By the time patent issues were solved, RCA had already invested heavily in conventional CRTs.[62]

1968 marks the release of Sony Trinitron brand with the model KV-1310, which was based on Aperture Grille technology. It was acclaimed to have improved the output brightness. The Trinitron screen was identical with its upright cylindrical shape due to its unique triple cathode single gun construction.

In 1987, flat-screen CRTs were developed by Zenith for computer monitors, reducing reflections and helping increase image contrast and brightness.[63][64] Such CRTs were expensive, which limited their use to computer monitors.[65] Attempts were made to produce flat-screen CRTs using inexpensive and widely available float glass.[66]

In 1990, the first CRTs with HD resolution were released to the market by Sony.[67]

In the mid-1990s, some 160 million CRTs were made per year.[68]

In the mid-2000s, Canon and Sony presented the surface-conduction electron-emitter display and field-emission displays, respectively. They both were flat-panel displays that had one (SED) or several (FED) electron emitters per subpixel in place of electron guns. The electron emitters were placed on a sheet of glass and the electrons were accelerated to a nearby sheet of glass with phosphors using an anode voltage. The electrons were not focused, making each subpixel essentially a flood beam CRT. They were never put into mass production as LCD technology was significantly cheaper, eliminating the market for such displays.[69]

The last large-scale manufacturer of (in this case, recycled)[70] CRTs, Videocon, ceased in 2015.[71][72] CRT TVs stopped being made around the same time.[73]

In 2015, several CRT manufacturers were convicted in the US for price fixing. The same occurred in Canada in 2018.[74][75]

Worldwide sales of CRT computer monitors peaked in 2000, at 90 million units, while those of CRT TVs peaked in 2005 at 130 million units.[76]

Decline

Beginning in the late 90s to the early 2000s, CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size,[77] largely because of their lower bulk.[78] Among the first manufacturers to stop CRT production was Hitachi in 2001,[79][80] followed by Sony in Japan in 2004,[81] Flat-panel displays dropped in price and started significantly displacing cathode-ray tubes in the 2000s. LCD monitor sales began exceeding those of CRTs in 2003–2004[82][83][84] and LCD TV sales started exceeding those of CRTs in some markets in 2005.[85]

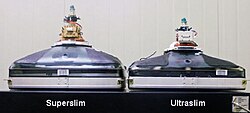

Despite being a mainstay of display technology for decades, CRT-based computer monitors and televisions are now virtually a dead technology. Demand for CRT screens dropped in the late 2000s.[86] Despite efforts from Samsung and LG to make CRTs competitive with their LCD and plasma counterparts, offering slimmer and cheaper models to compete with similarly sized and more expensive LCDs,[87][88][89][90][91] CRTs eventually became obsolete and were relegated to developing markets once LCDs fell in price, with their lower bulk, weight and ability to be wall mounted coming as pluses.

Some industries still use CRTs because it is either too much effort, downtime, and/or cost to replace them, or there is no substitute available; a notable example is the airline industry. Planes such as the Boeing 747-400 and the Airbus A320 used CRT instruments in their glass cockpits instead of mechanical instruments.[92] Airlines such as Lufthansa still use CRT technology, which also uses floppy disks for navigation updates.[93] They are also used in some military equipment for similar reasons.

As of 2022, at least one company manufactures new CRTs for these markets.[94]

A popular consumer usage of CRTs is for retrogaming. Some games are impossible to play without CRT display hardware, and some games play better. Reasons for this include:

- CRTs refresh faster than LCDs, because they use interlaced lines.

- CRTs are able to correctly display certain oddball resolutions, such as the 256x224 resolution of the Nintendo Entertainment System (NES).[95]

- Light guns only work on CRTs because they depend on the progressive timing properties of CRTs.

Construction

Body

The body of a CRT is usually made up of three parts: A screen/faceplate/panel, a cone/funnel, and a neck.[96][97][98][99][100] The joined screen, funnel and neck are known as the bulb or envelope.[38]

The neck is made from a glass tube[101] while the funnel and screen are made by pouring and then pressing glass into a mold.[102][103][104][105][106] The glass, known as CRT glass[107][108] or TV glass,[109] needs special properties to shield against x-rays while providing adequate light transmission in the screen or being very electrically insulating in the funnel and neck. The formulation that gives the glass its properties is also known as the melt. The glass is of very high quality, being almost contaminant and defect free. Most of the costs associated with glass production come from the energy used to melt the raw materials into glass. Glass furnaces for CRT glass production have several taps to allow molds to be replaced without stopping the furnace, to allow production of CRTs of several sizes. Only the glass used on the screen needs to have precise optical properties. The optical properties of the glass used on the screen affects color reproduction and purity in Color CRTs. Transmittance, or how transparent the glass is, may be adjusted to be more transparent to certain colors (wavelengths) of light. Transmittance is measured at the center of the screen with a 546 nm wavelength light, and a 10.16mm thick screen. Transmittance goes down with increasing thickness. Standard transmittances for Color CRT screens are 86%, 73%, 57%, 46%, 42% and 30%. Lower transmittances are used to improve image contrast but they put more stress on the electron gun, requiring more power on the electron gun for a higher electron beam power to light the phosphors more brightly to compensate for the reduced transmittance.[65][110] The transmittance must be uniform across the screen to ensure color purity. The radius (curvature) of screens has increased (grown less curved) over time, from 30 to 68 inches, ultimately evolving into completely flat screens, reducing reflections. The thickness of both curved[111] and flat screens gradually increases from the center outwards, and with it, transmittance is gradually reduced. This means that flat-screen CRTs may not be completely flat on the inside.[111][112] The glass used in CRTs arrives from the glass factory to the CRT factory as either separate screens and funnels with fused necks, for Color CRTs, or as bulbs made up of a fused screen, funnel and neck. There were several glass formulations for different types of CRTs, that were classified using codes specific to each glass manufacturer. The compositions of the melts were also specific to each manufacturer.[113] Those optimized for high color purity and contrast were doped with Neodymium, while those for monochrome CRTs were tinted to differing levels, depending on the formulation used and had transmittances of 42% or 30%.[114] Purity is ensuring that the correct colors are activated (for example, ensuring that red is displayed uniformly across the screen) while convergence ensures that images are not distorted. Convergence may be modified using a cross hatch pattern.[115][116][117]

CRT glass used to be made by dedicated companies[118] such as AGC Inc.,[119][120][121] O-I Glass,[122] Samsung Corning Precision Materials,[123] Corning Inc.,[124][125] and Nippon Electric Glass;[126] others such as Videocon, Sony for the US market and Thomson made their own glass.[127][128][129][130][131]

The funnel and the neck are made of leaded potash-soda glass or lead silicate glass[7] formulation to shield against x-rays generated by high voltage electrons as they decelerate after striking a target, such as the phosphor screen or shadow mask of a color CRT. The velocity of the electrons depends on the anode voltage of the CRT; the higher the voltage, the higher the speed.[132] The amount of x-rays emitted by a CRT can also lowered by reducing the brightness of the image.[133][134][135][99] Leaded glass is used because it is inexpensive, while also shielding heavily against x-rays, although some funnels may also contain barium.[136][137][138][114] The screen is usually instead made out of a special lead-free silicate[7] glass formulation with barium and strontium to shield against x-rays. Another glass formulation uses 2-3% of lead on the screen.[99] Monochrome CRTs may have a tinted barium-lead glass formulation in both the screen and funnel, with a potash-soda lead glass in the neck; the potash-soda and barium-lead formulations have different thermal expansion coefficients. The glass used in the neck must be an excellent electrical insulator to contain the voltages used in the electron optics of the electron gun, such as focusing lenses. The lead in the glass causes it to brown (darken) with use due to x-rays, usually the CRT cathode wears out due to cathode poisoning before browning becomes apparent. The glass formulation determines the highest possible anode voltage and hence the maximum possible CRT screen size. For color, maximum voltages are often 24 to 32 kV, while for monochrome it is usually 21 or 24.5 kV,[139] limiting the size of monochrome CRTs to 21 inches, or approx. 1 kV per inch. The voltage needed depends on the size and type of CRT.[140] Since the formulations are different, they must be compatible with one another, having similar thermal expansion coefficients.[114] The screen may also have an anti-glare or anti-reflective coating,[141][110][142] or be ground to prevent reflections.[143] CRTs may also have an anti-static coating.[110][144][65]

The leaded glass in the funnels of CRTs may contain 21 to 25% of lead oxide (PbO),[145][146][113] The neck may contain 30 to 40% of lead oxide,[147][148] and the screen may contain 12% of barium oxide, and 12% of strontium oxide.[7] A typical CRT contains several kilograms of lead as lead oxide in the glass[100] depending on its size; 12 inch CRTs contain 0.5 kg of lead in total while 32 inch CRTs contain up to 3 kg.[7] Strontium oxide began being used in CRTs, its major application, in the 1970s.[149][150][151]

Some early CRTs used a metal funnel insulated with polyethylene instead of glass with conductive material.[54] Others had ceramic or blown pyrex instead of pressed glass funnels.[152][153][40][154][155] Early CRTs did not have a dedicated anode cap connection; the funnel was the anode connection, so it was live during operation.[156]

The funnel is coated on the inside and outside with a conductive coating,[157][158] making the funnel a capacitor, helping stabilize and filter the anode voltage of the CRT, and significantly reducing the amount of time needed to turn on a CRT. The stability provided by the coating solved problems inherent to early power supply designs, as they used vacuum tubes. Because the funnel is used as a capacitor, the glass used in the funnel must be an excellent electrical insulator (dielectric). The inner coating has a positive voltage (the anode voltage that can be several kV) while the outer coating is connected to ground. CRTs powered by more modern power supplies do not need to be connected to ground, due to the more robust design of modern power supplies. The value of the capacitor formed by the funnel is .005-.01uF, although at the voltage the anode is normally supplied with. The capacitor formed by the funnel can also suffer from dielectric absorption, similarly to other types of capacitors.[159][139][160][161][157][114] Because of this CRTs have to be discharged[162] before handling to prevent injury.

The depth of a CRT is related to its screen size.[163] Usual deflection angles were 90° for computer monitor CRTs and small CRTs and 110° which was the standard in larger TV CRTs, with 120 or 125° being used in slim CRTs made since 2001–2005 in an attempt to compete with LCD TVs. [164][110][90][98][165] Over time, deflection angles increased as they became practical, from 50° in 1938 to 110° in 1959,[22] and 125° in the 2000s. 140° deflection CRTs were researched but never commercialized, as convergence problems were never resolved.[166]

Size and weight

The size of the screen of a CRT is measured in two ways: the size of the screen or the face diagonal, and the viewable image size/area or viewable screen diagonal, which is the part of the screen with phosphor. The size of the screen is the viewable image size plus its black edges which are not coated with phosphor.[167][158][168] The viewable image may be perfectly square or rectangular while the edges of the CRT are black and have a curvature (such as in black stripe CRTs) or the edges may be black and truly flat (such as in Flatron CRTs),[111][131][169] or the edges of the image may follow the curvature of the edges of the CRT, which may be the case in CRTs without and with black edges and curved edges.[170][171][172] Black stripe CRTs were first made by Toshiba in 1972.[131]

Small CRTs below 3 inches were made for handheld televisions such as the MTV-1 and viewfinders in camcorders. In these, there may be no black edges, that are however truly flat.[173][160][174][175][176]

Most of the weight of a CRT comes from the thick glass screen, which comprises 65% of the total weight of a CRT. The funnel and neck glass comprise the remaining 30% and 5% respectively. The glass in the funnel is thinner than on the screen.[7][6] Chemically or thermally tempered glass may be used to reduce the weight of the CRT glass.[177][178][179][180]

Anode

The outer conductive coating is connected to ground while the inner conductive coating is connected using the anode button/cap through a series of capacitors and diodes (a Cockcroft–Walton generator) to the high voltage flyback transformer; the inner coating is the anode of the CRT,[181] which, together with an electrode in the electron gun, is also known as the final anode.[182][183] The inner coating is connected to the electrode using springs. The electrode forms part of a bipotential lens.[183][184] The capacitors and diodes serve as a voltage multiplier for the current delivered by the flyback.

For the inner funnel coating, monochrome CRTs use aluminum while color CRTs use aquadag;[114] Some CRTs may use iron oxide on the inside.[7] On the outside, most CRTs (but not all)[185] use aquadag.[186] Aquadag is an electrically conductive graphite-based paint. In color CRTs, the aquadag is sprayed onto the interior of the funnel[187][114] whereas historically aquadag was painted into the interior of monochrome CRTs.[22]

The anode is used to accelerate the electrons towards the screen and also collects the secondary electrons that are emitted by the phosphor particles in the vacuum of the CRT.[188][189][190][191][22]

The anode cap connection in modern CRTs must be able to handle up to 55–60 kV depending on the size and brightness of the CRT. Higher voltages allow for larger CRTs, higher image brightness, or a tradeoff between the two.[192][140] It consists of a metal clip that expands on the inside of an anode button that is embedded on the funnel glass of the CRT.[193][194] The connection is insulated by a silicone suction cup, possibly also using silicone grease to prevent corona discharge.[195][196]

The anode button must be specially shaped to establish a hermetic seal between the button and funnel. X-rays may leak through the anode button, although that may not be the case in newer CRTs starting from the late 1970s to early 1980s, thanks to a new button and clip design.[140] The button may consist of a set of 3 nested cups, with the outermost cup being made of a Nickel–Chromium–Iron alloy containing 40 to 49% of Nickel and 3 to 6% of Chromium to make the button easy to fuse to the funnel glass, with a first inner cup made of thick inexpensive iron to shield against x-rays, and with the second innermost cup also being made of iron or any other electrically conductive metal to connect to the clip. The cups must be heat resistant enough and have similar thermal expansion coefficients similar to that of the funnel glass to withstand being fused to the funnel glass. The inner side of the button is connected to the inner conductive coating of the CRT.[189] The anode button may be attached to the funnel while its being pressed into shape in a mold.[197][198][140] Alternatively, the x-ray shielding may instead be built into the clip.[199]

The flyback transformer is also known as an IHVT (Integrated High Voltage Transformer) if it includes a voltage multiplier. The flyback uses a ceramic or powdered iron core to enable efficient operation at high frequencies. The flyback contains one primary and many secondary windings that provide several different voltages. The main secondary winding supplies the voltage multiplier with voltage pulses to ultimately supply the CRT with the high anode voltage it uses, while the remaining windings supply the CRT's filament voltage, keying pulses, focus voltage and voltages derived from the scan raster. When the transformer is turned off, the flyback's magnetic field quickly collapses which induces high voltage in its windings. The speed at which the magnetic field collapses determines the voltage that is induced, so the voltage increases alongside its speed. A capacitor (Retrace Timing Capacitor) or series of capacitors (to provide redundancy) is used to slow the collapse of the magnetic field.[200][201]

The design of the high voltage power supply in a product using a CRT has an influence in the amount of x-rays emitted by the CRT. The amount of emitted x-rays increases with both higher voltages and currents. If the product such as a TV set uses an unregulated high voltage power supply, meaning that anode and focus voltage go down with increasing electron current when displaying a bright image, the amount of emitted x-rays is as its highest when the CRT is displaying a moderately bright images, since when displaying dark or bright images, the higher anode voltage counteracts the lower electron beam current and vice versa respectively. The high voltage regulator and rectifier vacuum tubes in some old CRT TV sets may also emit x-rays.[202]

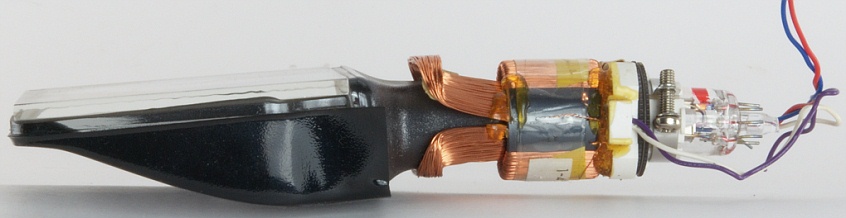

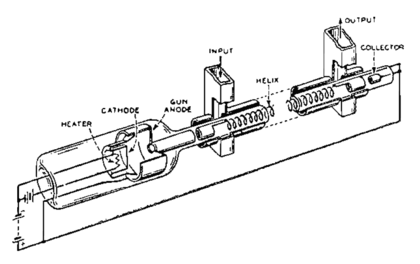

Electron gun

The electron gun emits the electrons that ultimately hit the phosphors on the screen of the CRT. The electron gun contains a heater, which heats a cathode, which generates electrons that, using grids, are focused and ultimately accelerated into the screen of the CRT. The acceleration occurs in conjunction with the inner aluminum or aquadag coating of the CRT. The electron gun is positioned so that it aims at the center of the screen.[183] It is inside the neck of the CRT, and it is held together and mounted to the neck using glass beads or glass support rods, which are the glass strips on the electron gun.[22][183][203] The electron gun is made separately and then placed inside the neck through a process called "winding", or sealing.[66][204][205][206][207][208] The electron gun has a glass wafer that is fused to the neck of the CRT. The connections to the electron gun penetrate the glass wafer.[205][209] Once the electron gun is inside the neck, its metal parts (grids) are arced between each other using high voltage to smooth any rough edges in a process called spot knocking, to prevent the rough edges in the grids from generating secondary electrons.[210][211][212]

Construction and method of operation

It has a hot cathode that is heated by a tungsten filament heating element; the heater may draw 0.5 to 2 A of current depending on the CRT. The voltage applied to the heater can affect the life of the CRT.[213][214] Heating the cathode energizes the electrons in it, aiding electron emission,[215] while at the same time current is supplied to the cathode; typically anywhere from 140 mA at 1.5 V to 600 mA at 6.3 V.[216] The cathode creates an electron cloud (emits electrons) whose electrons are extracted, accelerated and focused into an electron beam.[22] Color CRTs have three cathodes: one for red, green and blue. The heater sits inside the cathode but does not touch it; the cathode has its own separate electrical connection. The cathode is coated onto a piece of nickel which provides the electrical connection and structural support; the heater sits inside this piece without touching it.[181][217][218][219]

There are several shortcircuits that can occur in a CRT electron gun. One is a heater-to-cathode short, that causes the cathode to permanently emit electrons which may cause an image with a bright red, green or blue tint with retrace lines, depending on the cathode (s) affected. Alternatively, the cathode may short to the control grid, possibly causing similar effects, or, the control grid and screen grid (G2)[220] can short causing a very dark image or no image at all. The cathode may be surrounded by a shield to prevent sputtering.[221][222]

The cathode is a layer of barium oxide which is coated on a piece of nickel for electrical and mechanical support.[223][139] The barium oxide must be activated by heating to enable it to release electrons. Activation is necessary because barium oxide is not stable in air, so it is applied to the cathode as barium carbonate, which cannot emit electrons. Activation heats the barium carbonate to decompose it into barium oxide and carbon dioxide while forming a thin layer of metallic barium on the cathode.[224][223] Activation occurs during evacuation of (at the same time a vacuum is formed in) the CRT. After activation the oxide can become damaged by several common gases such as water vapor, carbon dioxide, and oxygen.[225] Alternatively, barium strontium calcium carbonate may be used instead of barium carbonate, yielding barium, strontium and calcium oxides after activation.[226][22] During operation, the barium oxide is heated to 800-1000°C, at which point it starts shedding electrons.[227][139][215]

Since it is a hot cathode, it is prone to cathode poisoning, which is the formation of a positive ion layer that prevents the cathode from emitting electrons, reducing image brightness significantly or completely and causing focus and intensity to be affected by the frequency of the video signal preventing detailed images from being displayed by the CRT. The positive ions come from leftover air molecules inside the CRT or from the cathode itself[22] that react over time with the surface of the hot cathode.[228][222] Reducing metals such as manganese, zirconium, magnesium, aluminum or titanium may be added to the piece of nickel to lengthen the life of the cathode, as during activation, the reducing metals diffuse into the barium oxide, improving its lifespan, especially at high electron beam currents.[229] In color CRTs with red, green and blue cathodes, one or more cathodes may be affected independently of the others, causing total or partial loss of one or more colors.[222] CRTs can wear or burn out due to cathode poisoning. Cathode poisoning is accelerated by increased cathode current (overdriving).[230] In color CRTs, since there are three cathodes, one for red, green and blue, a single or more poisoned cathode may cause the partial or complete loss of one or more colors, tinting the image.[222] The layer may also act as a capacitor in series with the cathode, inducing thermal lag. The cathode may instead be made of scandium oxide or incorporate it as a dopant, to delay cathode poisoning, extending the life of the cathode by up to 15%.[231][139][232]

The amount of electrons generated by the cathodes is related to their surface area. A cathode with more surface area creates more electrons, in a larger electron cloud, which makes focusing the electron cloud into an electron beam more difficult.[230] Normally, only a part of the cathode emits electrons unless the CRT displays images with parts that are at full image brightness; only the parts at full brightness cause all of the cathode to emit electrons. The area of the cathode that emits electrons grows from the center outwards as brightness increases, so cathode wear may be uneven. When only the center of the cathode is worn, the CRT may light brightly those parts of images that have full image brightness but not show darker parts of images at all, in such a case the CRT displays a poor gamma characteristic.[222]

The second (screen) grid of the gun (G2) accelerates the electrons towards the screen using several hundred DC volts. A negative current[233] is applied to the first (control) grid (G1) to converge the electron beam. G1 in practice is a Wehnelt cylinder.[216][234] The brightness of the screen is not controlled by varying the anode voltage nor the electron beam current (they are never varied) despite them having an influence on image brightness, rather image brightness is controlled by varying the difference in voltage between the cathode and the G1 control grid. A third grid (G3) electrostatically focuses the electron beam before it is deflected and accelerated by the anode voltage onto the screen.[235] Electrostatic focusing of the electron beam may be accomplished using an Einzel lens energized at up to 600 volts.[236][224] Before electrostatic focusing, focusing the electron beam required a large, heavy and complex mechanical focusing system placed outside the electron gun.[156]

However, electrostatic focusing cannot be accomplished near the final anode of the CRT due to its high voltage in the dozens of Kilovolts, so a high voltage (≈600[237] to 8000 volt) electrode, together with an electrode at the final anode voltage of the CRT, may be used for focusing instead. Such an arrangement is called a bipotential lens, which also offers higher performance than an Einzel lens, or, focusing may be accomplished using a magnetic focusing coil together with a high anode voltage of dozens of kilovolts. However, magnetic focusing is expensive to implement, so it is rarely used in practice.[181][224][238][239] Some CRTs may use two grids and lenses to focus the electron beam.[231] The focus voltage is generated in the flyback using a subset of the flyback's high voltage winding in conjunction with a resistive voltage divider. The focus electrode is connected alongside the other connections that are in the neck of the CRT.[240]

There is a voltage called cutoff voltage which is the voltage that creates black on the screen since it causes the image on the screen created by the electron beam to disappear, the voltage is applied to G1. In a color CRT with three guns, the guns have different cutoff voltages. Many CRTs share grid G1 and G2 across all three guns, increasing image brightness and simplifying adjustment since on such CRTs there is a single cutoff voltage for all three guns (since G1 is shared across all guns).[183] but placing additional stress on the video amplifier used to feed video into the electron gun's cathodes, since the cutoff voltage becomes higher. Monochrome CRTs do not suffer from this problem. In monochrome CRTs video is fed to the gun by varying the voltage on the first control grid.[241][156]

During retracing of the electron beam, the preamplifier that feeds the video amplifier is disabled and the video amplifier is biased to a voltage higher than the cutoff voltage to prevent retrace lines from showing, or G1 can have a large negative voltage applied to it to prevent electrons from getting out of the cathode.[22] This is known as blanking. (see Vertical blanking interval and Horizontal blanking interval.) Incorrect biasing can lead to visible retrace lines on one or more colors, creating retrace lines that are tinted or white (for example, tinted red if the red color is affected, tinted magenta if the red and blue colors are affected, and white if all colors are affected).[242][243][244] Alternatively, the amplifier may be driven by a video processor that also introduces an OSD (On Screen Display) into the video stream that is fed into the amplifier, using a fast blanking signal.[245] TV sets and computer monitors that incorporate CRTs need a DC restoration circuit to provide a video signal to the CRT with a DC component, restoring the original brightness of different parts of the image.[246]

The electron beam may be affected by the earth's magnetic field, causing it to normally enter the focusing lens off-center; this can be corrected using astigmation controls. Astigmation controls are both magnetic and electronic (dynamic); magnetic does most of the work while electronic is used for fine adjustments.[247] One of the ends of the electron gun has a glass disk, the edges of which are fused with the edge of the neck of the CRT, possibly using frit;[248] the metal leads that connect the electron gun to the outside pass through the disk.[249]

Some electron guns have a quadrupole lens with dynamic focus to alter the shape and adjust the focus of the electron beam, varying the focus voltage depending on the position of the electron beam to maintain image sharpness across the entire screen, specially at the corners.[110][250][251][252][253] They may also have a bleeder resistor to derive voltages for the grids from the final anode voltage.[254][255][256]

After the CRTs were manufactured, they were aged to allow cathode emission to stabilize.[257][258]

The electron guns in color CRTs are driven by a video amplifier which takes a signal per color channel and amplifies it to 40-170v per channel, to be fed into the electron gun's cathodes;[244] each electron gun has its own channel (one per color) and all channels may be driven by the same amplifier, which internally has three separate channels.[259] The amplifier's capabilities limit the resolution, refresh rate and contrast ratio of the CRT, as the amplifier needs to provide high bandwidth and voltage variations at the same time; higher resolutions and refresh rates need higher bandwidths (speed at which voltage can be varied and thus switching between black and white) and higher contrast ratios need higher voltage variations or amplitude for lower black and higher white levels. 30Mhz of bandwidth can usually provide 720p or 1080i resolution, while 20Mhz usually provides around 600 (horizontal, from top to bottom) lines of resolution, for example.[260][244] The difference in voltage between the cathode and the control grid is what modulates the electron beam, modulating its current and thus the brightness of the image.[222] The phosphors used in color CRTs produce different amounts of light for a given amount of energy, so to produce white on a color CRT, all three guns must output differing amounts of energy. The gun that outputs the most energy is the red gun since the red phosphor emits the least amount of light.[244]

Gamma

CRTs have a pronounced triode characteristic, which results in significant gamma (a nonlinear relationship in an electron gun between applied video voltage and beam intensity).[261]

Deflection

There are two types of deflection: magnetic and electrostatic. Magnetic is usually used in TVs and monitors as it allows for higher deflection angles (and hence shallower CRTs) and deflection power (which allows for higher electron beam current and hence brighter images)[262] while avoiding the need for high voltages for deflection of up to 2000 volts,[165] while oscilloscopes often use electrostatic deflection since the raw waveforms captured by the oscilloscope can be applied directly (after amplification) to the vertical electrostatic deflection plates inside the CRT.[263]

Magnetic deflection

Those that use magnetic deflection may use a yoke that has two pairs of deflection coils; one pair for vertical, and another for horizontal deflection.[264] The yoke can be bonded (be integral) or removable. Those that were bonded used glue[265] or a plastic[266] to bond the yoke to the area between the neck and the funnel of the CRT while those with removable yokes are clamped.[267][116] The yoke generates heat whose removal is essential since the conductivity of glass goes up with increasing temperature, the glass needs to be insulating for the CRT to remain usable as a capacitor. The temperature of the glass below the yoke is thus checked during the design of a new yoke.[139] The yoke contains the deflection and convergence coils with a ferrite core to reduce loss of magnetic force[268][264] as well as the magnetized rings used to align or adjust the electron beams in color CRTs (The color purity and convergence rings, for example)[269] and monochrome CRTs.[270][271] The yoke may be connected using a connector, the order in which the deflection coils of the yoke are connected determines the orientation of the image displayed by the CRT.[162] The deflection coils may be held in place using polyurethane glue.[265]

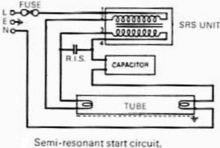

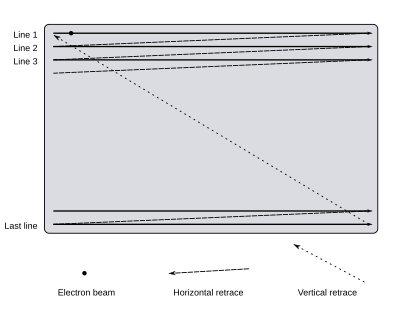

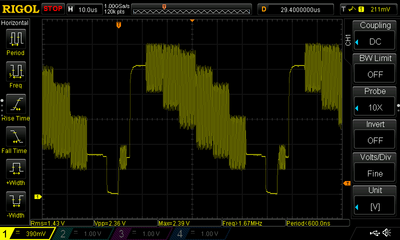

The deflection coils are driven by sawtooth signals[272][273][244] that may be delivered through VGA as horizontal and vertical sync signals.[274] A CRT needs two deflection circuits: a horizontal and a vertical circuit, which are similar except that the horizontal circuit runs at a much higher frequency (a Horizontal scan rate) of 15 to 240 kHz depending on the refresh rate of the CRT and the number of horizontal lines to be drawn (the vertical resolution of the CRT). The higher frequency makes it more susceptible to interference, so an automatic frequency control (AFC) circuit may be used to lock the phase of the horizontal deflection signal to that of a sync signal, to prevent the image from becoming distorted diagonally. The vertical frequency varies according to the refresh rate of the CRT. So a CRT with a 60 Hz refresh rate has a vertical deflection circuit running at 60 Hz. The horizontal and vertical deflection signals may be generated using two circuits that work differently; the horizontal deflection signal may be generated using a voltage controlled oscillator (VCO) while the vertical signal may be generated using a triggered relaxation oscillator. In many TVs, the frequencies at which the deflection coils run is in part determined by the inductance value of the coils.[275][244] CRTs had differing deflection angles; the higher the deflection angle, the shallower the CRT[276] for a given screen size, but at the cost of more deflection power and lower optical performance.[139][277]

Higher deflection power means more current[278] is sent to the deflection coils to bend the electron beam at a higher angle,[110] which in turn may generate more heat or require electronics that can handle the increased power.[277] Heat is generated due to resistive and core losses.[279] The deflection power is measured in mA per inch.[244] The vertical deflection coils may require approximately 24 volts while the horizontal deflection coils require approx. 120 volts to operate.

The deflection coils are driven by deflection amplifiers.[280] The horizontal deflection coils may also be driven in part by the horizontal output stage of a TV set. The stage contains a capacitor that is in series with the horizontal deflection coils that performs several functions, among them are: shaping the sawtooth deflection signal to match the curvature of the CRT and centering the image by preventing a DC bias from developing on the coil. At the beginning of retrace, the magnetic field of the coil collapses, causing the electron beam to return to the center of the screen, while at the same time the coil returns energy into capacitors, the energy of which is then used to force the electron beam to go to the left of the screen. [200]

Due to the high frequency at which the horizontal deflection coils operate, the energy in the deflection coils must be recycled to reduce heat dissipation. Recycling is done by transferring the energy in the deflection coils' magnetic field to a set of capacitors.[200] The voltage on the horizontal deflection coils is negative when the electron beam is on the left side of the screen and positive when the electron beam is on the right side of the screen. The energy required for deflection is dependent on the energy of the electrons.[281] Higher energy (voltage and/or current) electron beams need more energy to be deflected,[132] and are used to achieve higher image brightness.[282][283][192]

Electrostatic deflection

Mostly used in oscilloscopes. Deflection is carried out by applying a voltage across two pairs of plates, one for horizontal, and the other for vertical deflection. The electron beam is steered by varying the voltage difference across plates in a pair; For example, applying a voltage to the upper plate of the vertical deflection pair, while keeping the voltage in the bottom plate at 0 volts, will cause the electron beam to be deflected towards the upper part of the screen; increasing the voltage in the upper plate while keeping the bottom plate at 0 will cause the electron beam to be deflected to a higher point in the screen (will cause the beam to be deflected at a higher deflection angle). The same applies with the horizontal deflection plates. Increasing the length and proximity between plates in a pair can also increase the deflection angle.[284]

Burn-in

Burn-in is when images are physically "burned" into the screen of the CRT; this occurs due to degradation of the phosphors due to prolonged electron bombardment of the phosphors, and happens when a fixed image or logo is left for too long on the screen, causing it to appear as a "ghost" image or, in severe cases, also when the CRT is off. To counter this, screensavers were used in computers to minimize burn-in.[285] Burn-in is not exclusive to CRTs, as it also happens to plasma displays and OLED displays.

Evacuation

CRTs are evacuated or exhausted (a vacuum is formed) inside an oven at approx. 375–475 °C, in a process called baking or bake-out.[286] The evacuation process also outgasses any materials inside the CRT, while decomposing others such as the polyvinyl alcohol used to apply the phosphors.[287] The heating and cooling are done gradually to avoid inducing stress, stiffening and possibly cracking the glass; the oven heats the gases inside the CRT, increasing the speed of the gas molecules which increases the chances of them getting drawn out by the vacuum pump. The temperature of the CRT is kept to below that of the oven, and the oven starts to cool just after the CRT reaches 400 °C, or, the CRT was kept at a temperature higher than 400 °C for up to 15–55 minutes. The CRT was heated during or after evacuation, and the heat may have been used simultaneously to melt the frit in the CRT, joining the screen and funnel.[288][289][290] The pump used is a turbomolecular pump or a diffusion pump.[291][292][293][294] Formerly mercury vacuum pumps were also used.[295][296] After baking, the CRT is disconnected ("sealed or tipped off") from the vacuum pump.[297][298][299] The getter is then fired using an RF (induction) coil. The getter is usually in the funnel or in the neck of the CRT.[300][301] The getter material which is often barium-based, catches any remaining gas particles as it evaporates due to heating induced by the RF coil (that may be combined with exothermic heating within the material); the vapor fills the CRT, trapping any gas molecules that it encounters and condenses on the inside of the CRT forming a layer that contains trapped gas molecules. Hydrogen may be present in the material to help distribute the barium vapor. The material is heated to temperatures above 1000 °C, causing it to evaporate.[302][303][225] Partial loss of vacuum in a CRT can result in a hazy image, blue glowing in the neck of the CRT, flashovers, loss of cathode emission or focusing problems.[156] The vacuum inside of a CRT causes atmospheric pressure to exert (in a 27-inch CRT) a pressure of 5,800 pounds (2,600 kg) in total.[304]

Rebuilding

CRTs used to be rebuilt; repaired or refurbished. The rebuilding process included the disassembly of the CRT, the disassembly and repair or replacement of the electron gun(s), the removal and redeposition of phosphors and aquadag, etc. Rebuilding was popular until the 1960s because CRTs were expensive and wore out quickly, making repair worth it.[300] The last CRT rebuilder in the US closed in 2010,[305] and the last in Europe, RACS, which was located in France, closed in 2013.[306]

Reactivation

Also known as rejuvenation, the goal is to temporarily restore the brightness of a worn CRT. This is often done by carefully increasing the voltage on the cathode heater and the current and voltage on the control grids of the electron gun manually[citation needed]. Some rejuvenators can also fix heater-to-cathode shorts by running a capacitive discharge through the short.[222]

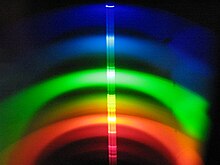

Phosphors

Phosphors in CRTs emit secondary electrons due to them being inside the vacuum of the CRT. The secondary electrons are collected by the anode of the CRT.[191] Secondary electrons generated by phosphors need to be collected to prevent charges from developing in the screen, which would lead to reduced image brightness[22] since the charge would repel the electron beam.

The phosphors used in CRTs often contain rare earth metals,[307][308][285] replacing earlier dimmer phosphors. Early red and green phosphors contained Cadmium,[309] and some black and white CRT phosphors also contained beryllium in the form of Zinc beryllium silicate,[50] although white phosphors containing cadmium, zinc and magnesium with silver, copper or manganese as dopants were also used.[22] The rare earth phosphors used in CRTs are more efficient (produce more light) than earlier phosphors.[310] The phosphors adhere to the screen because of Van der Waals and electrostatic forces. Phosphors composed of smaller particles adhere more strongly to the screen. The phosphors together with the carbon used to prevent light bleeding (in color CRTs) can be easily removed by scratching.[136][311]

Several dozen types of phosphors were available for CRTs.[312] Phosphors were classified according to color, persistence, luminance rise and fall curves, color depending on anode voltage (for phosphors used in penetration CRTs), Intended use, chemical composition, safety, sensitivity to burn-in, and secondary emission properties.[313] Examples of rare earth phosphors are yittrium oxide for red[314] and yittrium silicide for blue,[citation needed] while examples of earlier phosphors are copper cadmium sulfide for red,

SMPTE-C phosphors have properties defined by the SMPTE-C standard, which defines a color space of the same name. The standard prioritizes accurate color reproduction, which was made difficult by the different phosphors and color spaces used in the NTSC and PAL color systems. PAL TV sets have subjectively better color reproduction due to the use of saturated green phosphors, which have relatively long decay times that are tolerated in PAL since there is more time in PAL for phosphors to decay, due to its lower framerate. SMPTE-C phosphors were used in professional video monitors.[315][316]

The phosphor coating on monochrome and color CRTs may have an aluminum coating on its rear side used to reflect light forward, provide protection against ions to prevent ion burn by negative ions on the phosphor, manage heat generated by electrons colliding against the phosphor,[317] prevent static build up that could repel electrons from the screen, form part of the anode and collect the secondary electrons generated by the phosphors in the screen after being hit by the electron beam, providing the electrons with a return path.[318][139][319][317][22] The electron beam passes through the aluminum coating before hitting the phosphors on the screen; the aluminum attenuates the electron beam voltage by about 1 kv.[320][22][313] A film or lacquer may be applied to the phosphors to reduce the surface roughness of the surface formed by the phosphors to allow the aluminum coating to have a uniform surface and prevent it from touching the glass of the screen.[321][322] This is known as filming.[172] The lacquer contains solvents that are later evaporated; the lacquer may be chemically roughened to cause an aluminum coating with holes to be created to allow the solvents to escape.[322]

Phosphor persistence

Various phosphors are available depending upon the needs of the measurement or display application. The brightness, color, and persistence of the illumination depends upon the type of phosphor used on the CRT screen. Phosphors are available with persistences ranging from less than one microsecond to several seconds.[323] For visual observation of brief transient events, a long persistence phosphor may be desirable. For events which are fast and repetitive, or high frequency, a short-persistence phosphor is generally preferable.[324] The phosphor persistence must be low enough to avoid smearing or ghosting artifacts at high refresh rates.[110]

Limitations and workarounds

Blooming

Variations in anode voltage can lead to variations in brightness in parts or all of the image, in addition to blooming, shrinkage or the image getting zoomed in or out. Lower voltages lead to blooming and zooming in, while higher voltages do the opposite.[325][326] Some blooming is unavoidable, which can be seen as bright areas of an image that expand, distorting or pushing aside surrounding darker areas of the same image. Blooming occurs because bright areas have a higher electron beam current from the electron gun, making the beam wider and harder to focus. Poor voltage regulation causes focus and anode voltage to go down with increasing electron beam current.[202]

Doming

Doming is a phenomenon found on some CRT televisions in which parts of the shadow mask become heated. In televisions that exhibit this behavior, it tends to occur in high-contrast scenes in which there is a largely dark scene with one or more localized bright spots. As the electron beam hits the shadow mask in these areas it heats unevenly. The shadow mask warps due to the heat differences, which causes the electron gun to hit the wrong colored phosphors and incorrect colors to be displayed in the affected area.[327] Thermal expansion causes the shadow mask to expand by around 100 microns.[328][329][330][331]

During normal operation, the shadow mask is heated to around 80–90 °C.[332] Bright areas of images heat the shadow mask more than dark areas, leading to uneven heating of the shadow mask and warping (blooming) due to thermal expansion caused by heating by increased electron beam current.[333][334] The shadow mask is usually made of steel but it can be made of Invar[115] (a low-thermal expansion Nickel-Iron alloy) as it withstands two to three times more current than conventional masks without noticeable warping,[110][335][64] while making higher resolution CRTs easier to achieve.[336] Coatings that dissipate heat may be applied on the shadow mask to limit blooming[337][338] in a process called blackening.[339][340]

Bimetal springs may be used in CRTs used in TVs to compensate for warping that occurs as the electron beam heats the shadow mask, causing thermal expansion.[63] The shadow mask is installed to the screen using metal pieces[341] or a rail or frame[342][343][344] that is fused to the funnel or the screen glass respectively,[251] holding the shadow mask in tension to minimize warping (if the mask is flat, used in flat-screen CRT computer monitors) and allowing for higher image brightness and contrast.

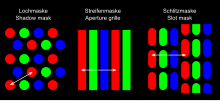

Aperture grille screens are brighter since they allow more electrons through, but they require support wires. They are also more resistant to warping.[110] Color CRTs need higher anode voltages than monochrome CRTs to achieve the same brightness since the shadow mask blocks most of the electron beam. Slot masks[51] and specially Aperture grilles do not block as many electrons resulting in a brighter image for a given anode voltage, but aperture grille CRTs are heavier.[115] Shadow masks block[345] 80–85%[333][332] of the electron beam while Aperture grilles allow more electrons to pass through.[346]

High voltage

Image brightness is related to the anode voltage and to the CRTs size, so higher voltages are needed for both larger screens[347] and higher image brightness. Image brightness is also controlled by the current of the electron beam.[230] Higher anode voltages and electron beam currents also mean higher amounts of x-rays and heat generation since the electrons have a higher speed and energy.[202] Leaded glass and special barium-strontium glass are used to block most x-ray emissions.

Size

Size is limited by anode voltage, as it would require a higher dielectric strength to prevent arcing (corona discharge) and the electrical losses and ozone generation it causes, without sacrificing image brightness. The weight of the CRT, which originates from the thick glass needed to safely sustain a vacuum, imposes a practical limit on the size of a CRT.[348] The 43-inch Sony PVM-4300 CRT monitor weighs 440 pounds (200 kg).[349] Smaller CRTs weigh significantly less, as an example, 32-inch CRTs weigh up to 163 pounds (74 kg) and 19-inch CRTs weigh up to 60 pounds (27 kg). For comparison, a 32-inch flat panel TV only weighs approx. 18 pounds (8.2 kg) and a 19-inch flat panel TV weighs 6.5 pounds (2.9 kg).[350]

Shadow masks become more difficult to make with increasing resolution and size.[336]

Limits imposed by deflection

At high deflection angles, resolutions and refresh rates (since higher resolutions and refresh rates require significantly higher frequencies to be applied to the horizontal deflection coils), the deflection yoke starts to produce large amounts of heat, due to the need to move the electron beam at a higher angle, which in turn requires exponentially larger amounts of power. As an example, to increase the deflection angle from 90 to 120°, power consumption of the yoke must also go up from 40 watts to 80 watts, and to increase it further from 120 to 150°, deflection power must again go up from 80 watts to 160 watts. This normally makes CRTs that go beyond certain deflection angles, resolutions and refresh rates impractical, since the coils would generate too much heat due to resistance caused by the skin effect, surface and eddy current losses, and/or possibly causing the glass underneath the coil to become conductive (as the electrical conductivity of glass decreases with increasing temperature). Some deflection yokes are designed to dissipate the heat that comes from their operation.[114][351][279][352][353][354] Higher deflection angles in color CRTs directly affect convergence at the corners of the screen which requires additional compensation circuitry to handle electron beam power and shape, leading to higher costs and power consumption.[355][356] Higher deflection angles allow a CRT of a given size to be slimmer, however they also impose more stress on the CRT envelope, specially on the panel, the seal between the panel and funnel and on the funnel. The funnel needs to be long enough to minimize stress, as a longer funnel can be better shaped to have lower stress.[98][357]

Comparison with other technologies

- LCD advantages over CRT: Lower bulk, power consumption and heat generation, higher refresh rates (up to 360 Hz),[358] higher contrast ratios

- CRT advantages over LCD: Better color reproduction, no motion blur, multisyncing available in many monitors, no input lag[359]

- OLED advantages over CRT: Lower bulk, similar color reproduction,[359] higher contrast ratios, similar refresh rates (over 60 Hz, up to 120 Hz)[360][361][362] except for computer monitors.[363]

On CRTs, refresh rate depends on resolution, both of which are ultimately limited by the maximum horizontal scanning frequency of the CRT. Motion blur also depends on the decay time of the phosphors. Phosphors that decay too slowly for a given refresh rate may cause smearing or motion blur on the image. In practice, CRTs are limited to a refresh rate of 160 Hz.[364] LCDs that can compete with OLED (Dual Layer, and mini-LED LCDs) are not available in high refresh rates, although quantum dot LCDs (QLEDs) are available in high refresh rates (up to 144 Hz)[365] and are competitive in color reproduction with OLEDs.[366]

CRT monitors can still outperform LCD and OLED monitors in input lag, as there is no signal processing between the CRT and the display connector of the monitor, since CRT monitors often use VGA which provides an analog signal that can be fed to a CRT directly. Video cards designed for use with CRTs may have a RAMDAC to generate the analog signals needed by the CRT.[367][11] Also, CRT monitors are often capable of displaying sharp images at several resolutions, an ability known as multisyncing.[368] Due to these reasons, CRTs are sometimes preferred by PC gamers in spite of their bulk, weight and heat generation.[369][359]

CRTs tend to be more durable than their flat panel counterparts,[11] though specialised LCDs that have similar durability also exist.

Types

CRTs were produced in two major categories, picture tubes and display tubes.[68] Picture tubes were used in TVs while display tubes were used in computer monitors. Display tubes had no overscan and were of higher resolution. Picture tube CRTs have overscan, meaning the actual edges of the image are not shown; this is deliberate to allow for adjustment variations between CRT TVs, preventing the ragged edges (due to blooming) of the image from being shown on screen. The shadow mask may have grooves that reflect away the electrons that do not hit the screen due to overscan.[370][110] Color picture tubes used in TVs were also known as CPTs.[371] CRTs are also sometimes called Braun tubes.[372][373]

Monochrome CRTs

If the CRT is a black and white (B&W or monochrome) CRT, there is a single electron gun in the neck and the funnel is coated on the inside with aluminum that has been applied by evaporation; the aluminum is evaporated in a vacuum and allowed to condense on the inside of the CRT.[172] Aluminum eliminates the need for ion traps, necessary to prevent ion burn on the phosphor, while also reflecting light generated by the phosphor towards the screen, managing heat and absorbing electrons providing a return path for them; previously funnels were coated on the inside with aquadag, used because it can be applied like paint;[161] the phosphors were left uncoated.[22] Aluminum started being applied to CRTs in the 1950s, coating the inside of the CRT including the phosphors, which also increased image brightness since the aluminum reflected light (that would otherwise be lost inside the CRT) towards the outside of the CRT.[22][374][375][376] In aluminized monochrome CRTs, Aquadag is used on the outside. There is a single aluminum coating covering the funnel and the screen.[172]

The screen, funnel and neck are fused together into a single envelope, possibly using lead enamel seals, a hole is made in the funnel onto which the anode cap is installed and the phosphor, aquadag and aluminum are applied afterwards.[66] Previously monochrome CRTs used ion traps that required magnets; the magnet was used to deflect the electrons away from the more difficult to deflect ions, letting the electrons through while letting the ions collide into a sheet of metal inside the electron gun.[377][156][317] Ion burn results in premature wear of the phosphor. Since ions are harder to deflect than electrons, ion burn leaves a black dot in the center of the screen.[156][317]

The interior aquadag or aluminum coating was the anode and served to accelerate the electrons towards the screen, collect them after hitting the screen while serving as a capacitor together with the outer aquadag coating. The screen has a single uniform phosphor coating and no shadow mask, technically having no resolution limit.[378][163][379]

Monochrome CRTs may use ring magnets to adjust the centering of the electron beam and magnets around the deflection yoke to adjust the geometry of the image.[271][380]

Older monochrome CRT[381] without aluminum, only aquadag

Color CRTs

Color CRTs use three different phosphors which emit red, green, and blue light respectively. They are packed together in stripes (as in aperture grille designs) or clusters called "triads" (as in shadow mask CRTs).[382][383]

Color CRTs have three electron guns, one for each primary color, (red, green and blue) arranged either in a straight line (in-line) or in an equilateral triangular configuration (the guns are usually constructed as a single unit).[183][264][384][385][386] (The triangular configuration is often called "delta-gun", based on its relation to the shape of the Greek letter delta Δ.) The arrangement of the phosphors is the same as that of the electron guns.[183][387] A grille or mask absorbs the electrons that would otherwise hit the wrong phosphor.[388]

A shadow mask tube uses a metal plate with tiny holes, typically in a delta configuration, placed so that the electron beam only illuminates the correct phosphors on the face of the tube;[382] blocking all other electrons.[99] Shadow masks that use slots instead of holes are known as slot masks.[11] The holes or slots are tapered[389][390] so that the electrons that strike the inside of any hole will be reflected back, if they are not absorbed (e.g. due to local charge accumulation), instead of bouncing through the hole to strike a random (wrong) spot on the screen. Another type of color CRT (Trinitron) uses an aperture grille of tensioned vertical wires to achieve the same result.[388] The shadow mask has a single hole for each triad.[183] The shadow mask is usually 1/2 inch behind the screen.[115]

Trinitron CRTs were different from other color CRTs in that they had a single electron gun with three cathodes, an aperture grille which lets more electrons through, increasing image brightness (since the aperture grille does not block as many electrons), and a vertically cylindrical screen, rather than a curved screen.[391]

The three electron guns are in the neck (except for Trinitrons) and the red, green and blue phosphors on the screen may be separated by a black grid or matrix (called black stripe by Toshiba).[65]

The funnel is coated with aquadag on both sides while the screen has a separate aluminum coating applied in a vacuum.[183][114] The aluminum coating protects the phosphor from ions, absorbs secondary electrons, providing them with a return path, preventing them from electrostatically charging the screen which would then repel electrons and reduce image brightness, reflects the light from the phosphors forwards and helps manage heat. It also serves as the anode of the CRT together with the inner aquadag coating. The inner coating is electrically connected to an electrode of the electron gun using springs, forming the final anode.[184][183] The outer aquadag coating is connected to ground, possibly using a series of springs or a harness that makes contact with the aquadag.[392][393]

Shadow mask

The shadow mask absorbs or reflects electrons that would otherwise strike the wrong phosphor dots,[379] causing color purity issues (discoloration of images); in other words, when set up correctly, the shadow mask helps ensure color purity.[183] When the electrons strike the shadow mask, they release their energy as heat and x-rays. If the electrons have too much energy due to an anode voltage that is too high for example, the shadow mask can warp due to the heat, which can also happen during the Lehr baking at approx. 435 °C of the frit seal between the faceplate and the funnel of the CRT.[345][394]

Shadow masks were replaced in TVs by slot masks in the 1970s, since slot masks let more electrons through, increasing image brightness. Shadow masks may be connected electrically to the anode of the CRT.[395][51][396][397] Trinitron used a single electron gun with three cathodes instead of three complete guns. CRT PC monitors usually use shadow masks, except for Sony's Trinitron, Mitsubishi's Diamondtron and NEC's Cromaclear; Trinitron and Diamondtron use aperture grilles while Cromaclear uses a slot mask. Some shadow mask CRTs have color phosphors that are smaller in diameter than the electron beams used to light them,[398] with the intention being to cover the entire phosphor, increasing image brightness.[399] Shadow masks may be pressed into a curved shape.[400][401][402]

Screen manufacture

Early color CRTs did not have a black matrix, which was introduced by Zenith in 1969, and Panasonic in 1970.[399][403][131] The black matrix eliminates light leaking from one phosphor to another since the black matrix isolates the phosphor dots from one another, so part of the electron beam touches the black matrix. This is also made necessary by warping of the shadow mask.[65][398] Light bleeding may still occur due to stray electrons striking the wrong phosphor dots. At high resolutions and refresh rates, phosphors only receive a very small amount of energy, limiting image brightness.[336]

Several methods were used to create the black matrix. One method coated the screen in photoresist such as dichromate-sensitized polyvinyl alcohol photoresist which was then dried and exposed; the unexposed areas were removed and the entire screen was coated in colloidal graphite to create a carbon film, and then hydrogen peroxide was used to remove the remaining photoresist alongside the carbon that was on top of it, creating holes that in turn created the black matrix. The photoresist had to be of the correct thickness to ensure sufficient adhesion to the screen, while the exposure step had to be controlled to avoid holes that were too small or large with ragged edges caused by light diffraction, ultimately limiting the maximum resolution of large color CRTs.[398] The holes were then filled with phosphor using the method described above. Another method used phosphors suspended in an aromatic diazonium salt that adhered to the screen when exposed to light; the phosphors were applied, then exposed to cause them to adhere to the screen, repeating the process once for each color. Then carbon was applied to the remaining areas of the screen while exposing the entire screen to light to create the black matrix, and a fixing process using an aqueous polymer solution was applied to the screen to make the phosphors and black matrix resistant to water.[403] Black chromium may be used instead of carbon in the black matrix.[398] Other methods were also used.[404][405][406][407]

The phosphors are applied using photolithography. The inner side of the screen is coated with phosphor particles suspended in PVA photoresist slurry,[408][409] which is then dried using infrared light,[410] exposed, and developed. The exposure is done using a "lighthouse" that uses an ultraviolet light source with a corrector lens to allow the CRT to achieve color purity. Removable shadow masks with spring-loaded clips are used as photomasks. The process is repeated with all colors. Usually the green phosphor is the first to be applied.[183][411][412][413] After phosphor application, the screen is baked to eliminate any organic chemicals (such as the PVA that was used to deposit the phosphor) that may remain on the screen.[403][414] Alternatively, the phosphors may be applied in a vacuum chamber by evaporating them and allowing them to condense on the screen, creating a very uniform coating.[231] Early color CRTs had their phosphors deposited using silkscreen printing.[43] Phosphors may have color filters over them (facing the viewer), contain pigment of the color emitted by the phosphor,[415][308] or be encapsulated in color filters to improve color purity and reproduction while reducing glare.[412][397] Poor exposure due to insufficient light leads to poor phosphor adhesion to the screen, which limits the maximum resolution of a CRT, as the smaller phosphor dots required for higher resolutions cannot receive as much light due to their smaller size.[416]

After the screen is coated with phosphor and aluminum and the shadow mask installed onto it the screen is bonded to the funnel using a glass frit that may contain 65 to 88% of lead oxide by weight. The lead oxide is necessary for the glass frit to have a low melting temperature. Boron oxide (III) may also present to stabilize the frit, with alumina powder as filler powder to control the thermal expansion of the frit.[417][145][7] The frit may be applied as a paste consisting of frit particles suspended in amyl acetate or in a polymer with an alkyl methacrylate monomer together with an organic solvent to dissolve the polymer and monomer.[418][419] The CRT is then baked in an oven in what is called a Lehr bake, to cure the frit, sealing the funnel and screen together. The frit contains a large quantity of lead, causing color CRTs to contain more lead than their monochrome counterparts. Monochrome CRTs on the other hand do not require frit; the funnel can be fused directly to the glass[99] by melting and joining the edges of the funnel and screen using gas flames. Frit is used in color CRTs to prevent deformation of the shadow mask and screen during the fusing process. The edges of the screen and funnel of the CRT are never melted.[183] A primer may be applied on the edges of the funnel and screen before the frit paste is applied to improve adhesion.[420] The Lehr bake consists of several successive steps that heat and then cool the CRT gradually until it reaches a temperature of 435 to 475 °C[418] (other sources may state different temperatures, such as 440 °C)[421] After the Lehr bake, the CRT is flushed with air or nitrogen to remove contaminants, the electron gun is inserted and sealed into the neck of the CRT, and a vacuum is formed on the CRT.[422][206]

Convergence and purity in color CRTs

Due to limitations in the dimensional precision with which CRTs can be manufactured economically, it has not been practically possible to build color CRTs in which three electron beams could be aligned to hit phosphors of respective color in acceptable coordination, solely on the basis of the geometric configuration of the electron gun axes and gun aperture positions, shadow mask apertures, etc. The shadow mask ensures that one beam will only hit spots of certain colors of phosphors, but minute variations in physical alignment of the internal parts among individual CRTs will cause variations in the exact alignment of the beams through the shadow mask, allowing some electrons from, for example, the red beam to hit, say, blue phosphors, unless some individual compensation is made for the variance among individual tubes.

Color convergence and color purity are two aspects of this single problem. Firstly, for correct color rendering it is necessary that regardless of where the beams are deflected on the screen, all three hit the same spot (and nominally pass through the same hole or slot) on the shadow mask.[clarification needed] This is called convergence.[423] More specifically, the convergence at the center of the screen (with no deflection field applied by the yoke) is called static convergence, and the convergence over the rest of the screen area (specially at the edges and corners) is called dynamic convergence.[116] The beams may converge at the center of the screen and yet stray from each other as they are deflected toward the edges; such a CRT would be said to have good static convergence but poor dynamic convergence. Secondly, each beam must only strike the phosphors of the color it is intended to strike and no others. This is called purity. Like convergence, there is static purity and dynamic purity, with the same meanings of "static" and "dynamic" as for convergence. Convergence and purity are distinct parameters; a CRT could have good purity but poor convergence, or vice versa. Poor convergence causes color "shadows" or "ghosts" along displayed edges and contours, as if the image on the screen were intaglio printed with poor registration. Poor purity causes objects on the screen to appear off-color while their edges remain sharp. Purity and convergence problems can occur at the same time, in the same or different areas of the screen or both over the whole screen, and either uniformly or to greater or lesser degrees over different parts of the screen.