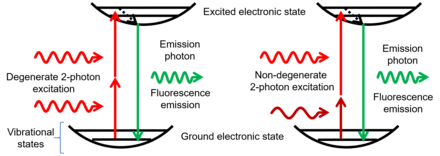

Non-degenerate two-photon absorption (ND-TPA or ND-2PA) [1] or two-color two-photon excitation[2] is a type of two-photon absorption (TPA) where two photons with different energies are (almost) simultaneously absorbed by a molecule, promoting a molecular electronic transition from a lower energy stateto a higher energy state. The sum of the energies of the two photons is equal to, or larger than, the total energy of the transition.

The probability of ND-TPA is quantified as the non-degenerate two-photon absorption cross section (ND-TPACS) and is an inherent property of molecules. ND-TPACS has been measured using Z-scan (pump-probe) techniques,[3] which measure the laser intensity decrease due to absorption, and fluorescence-based techniques,[4] which measure the fluorescence generated by the fluorophoresupon ND-TPA.

In ND-TPA, by absorbing the first photon, the molecule makes a transition to a virtual state and stays in the virtual state for an extremely short period of time (virtual state lifetime, VSL). If a second photon is absorbed during the VSL, the molecule makes a transition to the excited electronic state, otherwise it will relax back to the ground state. Therefore, the two photons are "almost" simultaneously absorbed in two-photon absorption. Based on the time–energy uncertainty relation, VSL is inversely proportional to the energy difference between the virtual state and the nearest real electronic state (i.e. the ground or a nearby excited state). Therefore, the closer the virtual state to the real state, the longer the VSL and the higher the probability of TPA. This means that in comparison to degenerate TPA, where the virtual state is in the middle of the ground and the excited state, ND-TPA has a larger absorption cross-section. This phenomenon is known as the resonance enhancement and is the main mechanism behind the observed increase in ND-TPACS of semiconductors [5] and fluorophores[6][7] in comparison to their degenerate TPA cross-sections.

ND-TPA has also been explored in two-photon microscopy for decreasing out-of-focus excitation,[8] increasing penetration depth,[9] increasing spatial resolution,[10] and extending the excitation wavelength range.[11][12]

https://en.wikipedia.org/wiki/Non-degenerate_two-photon_absorption

In optics, an erect image is one that appears right-side up. An image is formed when rays from a point on the original object meet again after passing through an optical system. In an erect image, directions are the same as those in the object, in contrast to an inverted image. It is one of the properties of images formed in a plane mirror. Some telescopes and other devices such as the camera obscura present an inverted image on the viewing surface. Mirrorsand compound prism elements can be used to achieve an erect image instead.

https://en.wikipedia.org/wiki/Erect_image

https://en.wikipedia.org/wiki/Pauli_exclusion_principle

A helium flash is a very brief thermal runaway nuclear fusion of large quantities of helium into carbon through the triple-alpha process in the core of low mass stars (between 0.8 solar masses (M☉) and 2.0 M☉[1]) during their red giant phase (the Sun is predicted to experience a flash 1.2 billion years after it leaves the main sequence). A much rarer runaway helium fusion process can also occur on the surface of accreting white dwarf stars.

Low-mass stars do not produce enough gravitational pressure to initiate normal helium fusion. As the hydrogen in the core is exhausted, some of the helium left behind is instead compacted into degenerate matter, supported against gravitational collapse by quantum mechanical pressure rather than thermal pressure. This increases the density and temperature of the core until it reaches approximately 100 million kelvin, which is hot enough to cause helium fusion (or "helium burning") in the core.

However, a fundamental quality of degenerate matter is that increases in temperature do not produce an increase in volume of the matter until the thermal pressure becomes so very high that it exceeds degeneracy pressure. In main sequence stars, thermal expansionregulates the core temperature, but in degenerate cores this does not occur. Helium fusion increases the temperature, which increases the fusion rate, which further increases the temperature in a runaway reaction. This produces a flash of very intense helium fusion that lasts only a few minutes, but briefly emits energy at a rate comparable to the entire Milky Way galaxy.

In the case of normal low-mass stars, the vast energy release causes much of the core to come out of degeneracy, allowing it to thermally expand, however, consuming as much energy as the total energy released by the helium flash, and any left-over energy is absorbed into the star's upper layers. Thus the helium flash is mostly undetectable to observation, and is described solely by astrophysical models. After the core's expansion and cooling, the star's surface rapidly cools and contracts in as little as 10,000 years until it is roughly 2% of its former radius and luminosity. It is estimated that the electron-degenerate helium core weighs about 40% of the star mass and that 6% of the core is converted into carbon.[2]

https://en.wikipedia.org/wiki/Helium_flash

Gravitational collapse is the contraction of an astronomical object due to the influence of its own gravity, which tends to draw matter inward toward the centre of gravity.[1] Gravitational collapse is a fundamental mechanism for structure formation in the universe. Over time an initial, relatively smooth distribution of matter will collapse to form pockets of higher density, typically creating a hierarchy of condensed structures such as clusters of galaxies, stellar groups, stars and planets.

A star is born through the gradual gravitational collapse of a cloud of interstellar matter. The compression caused by the collapse raises the temperature until thermonuclear fusion occurs at the center of the star, at which point the collapse gradually comes to a halt as the outward thermal pressure balances the gravitational forces. The star then exists in a state of dynamic equilibrium. Once all its energy sources are exhausted, a star will again collapse until it reaches a new equilibrium state.

https://en.wikipedia.org/wiki/Gravitational_collapse

Thus the thermal pressure from fusion is no longer sufficient to counter the gravitational collapse and create the hydrostatic equilibrium found in most stars. This causes the star to start contracting and increasing in temperature until it eventually becomes compressed enough for the helium core to become degenerate matter. This degeneracy pressure is finally sufficient to stop further collapse of the most central material but the rest of the core continues to contract and the temperature continues to rise until it reaches a point (≈1×108 K) at which the helium can ignite and start to fuse.[4][5][6]

https://en.wikipedia.org/wiki/Helium_flash

The explosive nature of the helium flash arises from its taking place in degenerate matter. Once the temperature reaches 100 million–200 million kelvin and helium fusion begins using the triple-alpha process, the temperature rapidly increases, further raising the helium fusion rate and, because degenerate matter is a good conductor of heat, widening the reaction region.

However, since degeneracy pressure (which is purely a function of density) is dominating thermal pressure (proportional to the product of density and temperature), the total pressure is only weakly dependent on temperature. Thus, the dramatic increase in temperature only causes a slight increase in pressure, so there is no stabilizing cooling expansion of the core.

This runaway reaction quickly climbs to about 100 billion times the star's normal energy production (for a few seconds) until the temperature increases to the point that thermal pressure again becomes dominant, eliminating the degeneracy. The core can then expand and cool down and a stable burning of helium will continue.[7]

A star with mass greater than about 2.25 M☉ starts to burn helium without its core becoming degenerate, and so does not exhibit this type of helium flash. In a very low-mass star (less than about 0.5 M☉), the core is never hot enough to ignite helium. The degenerate helium core will keep on contracting, and finally becomes a helium white dwarf.

The helium flash is not directly observable on the surface by electromagnetic radiation. The flash occurs in the core deep inside the star, and the net effect will be that all released energy is absorbed by the entire core, causing the degenerate state to become nondegenerate. Earlier computations indicated that a nondisruptive mass loss would be possible in some cases,[8] but later star modeling taking neutrino energy loss into account indicates no such mass loss.[9][10]

In a one solar mass star, the helium flash is estimated to release about 5×1041 J,[11] or about 0.3% of the energy release of a 1.5×1044 J type Ia supernova,[12] which is triggered by an analogous ignition of carbon fusion in a carbon–oxygen white dwarf.

Shell helium flashes are a somewhat analogous but much less violent, nonrunaway helium ignition event, taking place in the absence of degenerate matter. They occur periodically in asymptotic giant branch stars in a shell outside the core. This is late in the life of a star in its giant phase. The star has burnt most of the helium available in the core, which is now composed of carbon and oxygen. Helium fusion continues in a thin shell around this core, but then turns off as helium becomes depleted. This allows hydrogen fusion to start in a layer above the helium layer. After enough additional helium accumulates, helium fusion is reignited, leading to a thermal pulse which eventually causes the star to expand and brighten temporarily (the pulse in luminosity is delayed because it takes a number of years for the energy from restarted helium fusion to reach the surface[13]). Such pulses may last a few hundred years, and are thought to occur periodically every 10,000 to 100,000 years.[13] After the flash, helium fusion continues at an exponentially decaying rate for about 40% of the cycle as the helium shell is consumed.[13] Thermal pulses may cause a star to shed circumstellar shells of gas and dust.[citation needed]

https://en.wikipedia.org/wiki/Helium_flash

Complete spatial randomness (CSR) describes a point process whereby point events occur within a given study area in a completely random fashion. It is synonymous with a homogeneous spatial Poisson process.[1] Such a process is modeled using only one parameter , i.e. the density of points within the defined area. The term complete spatial randomness is commonly used in Applied Statistics in the context of examining certain point patterns, whereas in most other statistical contexts it is referred to the concept of a spatial Poisson process.[1]

https://en.wikipedia.org/wiki/Complete_spatial_randomness

The Euler number (Eu) is a dimensionless number used in fluid flow calculations. It expresses the relationship between a local pressure drop caused by a restriction and the kinetic energy per volume of the flow, and is used to characterize energy losses in the flow, where a perfect frictionless flow corresponds to an Euler number of 0. The inverse of the Euler number is referred to as the Ruark Number with the symbol Ru.

The Euler number is defined as

where

- is the density of the fluid.

- is the upstream pressure.

- is the downstream pressure.

- is a characteristic velocity of the flow.

Cavitation number[edit]

The cavitation number has a similar structure, but a different meaning and use:

The cavitation number (Ca) is a dimensionless number used in flow calculations. It expresses the relationship between the difference of a local absolute pressure from the vapor pressure and the kinetic energy per volume, and is used to characterize the potential of the flow to cavitate.

It is defined as

where

- is the density of the fluid.

- is the local pressure.

- is the vapor pressure of the fluid.

- is a characteristic velocity of the flow.

Cavitation number is among the very few means to characterize a cavitating flow in a fluidic system. When the upstream pressure increase velocity of the working fluid increases as well. However, the velocity increase rate is one order of magnitude higher than the pressure increase. This means that, cavitation number follows a decreasing trend while upstream pressure increases. The first moment that cavitating bubbles appear in a system, inception happens. The corresponding cavitation number at this moment is inception cavitation number. According to the discussion above, this number is the highest number recorded in a system. Researchers are often interested in recording inception of cavitating flow at relatively low upstream pressure when they are aiming for the non-destructive applications on this phenomenon. With the development of cavitating flow, Cavitation number decreases until supercavitation happens which is the highest velocity and flowrate that the system can pass. As a result, the lower cavitation number shows the higher intensity on the cavitating flow. After supercavitation, the system is incapable of passing more fluid. However, the upstream pressure is increasing. As a result, cavitation number starts to follow an increasing trend. This trend could be seen in many published articles in the literature.[1]

https://en.wikipedia.org/wiki/Euler_number_(physics)

Refraction is generally accompanied by partial reflection. When waves are refracted from a medium of lower propagation speed (higher refractive index) to a medium of higher speed—e.g., from water to air—the angle of refraction (between the outgoing ray and the surface normal) is greater than the angle of incidence (between the incoming ray and the normal). As the angle of incidence approaches a certain threshold, called the critical angle, the angle of refraction approaches 90°, at which the refracted ray becomes parallel to the boundary surface. As the angle of incidence increases beyond the critical angle, the conditions of refraction can no longer be satisfied, so there is no refracted ray, and the partial reflection becomes total. For visible light, the critical angle is about 49° for incidence from water to air, and about 42° for incidence from common glass to air.

https://en.wikipedia.org/wiki/Total_internal_reflection

However, it is sometimes useful and does not cause damage when the bubbles collapse away from machinery, such as in supercavitation.

https://en.wikipedia.org/wiki/Cavitation

https://en.wikipedia.org/wiki/Cavitation#Pumps_and_propellers

https://en.wikipedia.org/wiki/Water_tunnel_(hydrodynamic)

https://en.wikipedia.org/wiki/Water_hammer

A hydraulic accumulator is a pressure storage reservoir in which an incompressible hydraulic fluid is held under pressure that is applied by an external source of mechanical energy. The external source can be an engine, a spring, a raised weight, or a compressed gas.[note 1] An accumulator enables a hydraulic system to cope with extremes of demand using a less powerful pump, to respond more quickly to a temporary demand, and to smooth out pulsations. It is a type of energy storage device.

Compressed gas accumulators, also called hydro-pneumatic accumulators, are by far the most common type.

Types of accumulators[edit]

Towers[edit]

The first accumulators for William Armstrong's hydraulic dock machinery were simple raised water towers. Water was pumped to a tank at the top of these towers by steam pumps. When dock machinery required hydraulic power, the hydrostatic head of the water's height above ground provided the necessary pressure.

These simple accumulators were extremely tall. For instance, Grimsby Dock Tower, built in 1852, is 309 feet (94 m) tall. Because of their size, they were costly, and so were constructed for less than a decade. Around the same time, John Fowler was working on the construction of the ferry quay at nearby New Holland but could not use similar hydraulic power as the poor ground conditions did not permit a tall accumulator tower to be built. By the time Grimsby was opened, it was already obsolete as Armstrong had developed the more complex, but much smaller, weighted accumulator for use at New Holland.[1] In 1892 the original Grimsby tower's function was replaced, on Fowler's advice, by a smaller weighted accumulator on an adjacent dock, although the tower remains to this day as a well-known landmark.

Other surviving towers include one adjacent to East Float in Birkenhead, England, and another located at the Bramley-Moore Dock, Liverpool, England. The latter tower is to be renovated as part of plans for the proposed development of the area associated with the construction of a new football stadium for Everton F.C.

Raised weight[edit]

A raised weight accumulator consists of a vertical cylinder containing fluid connected to the hydraulic line. The cylinder is closed by a piston on which a series of weights are placed that exert a downward force on the piston and thereby pressurizes the fluid in the cylinder. In contrast to compressed gas and spring accumulators, this type delivers a nearly constant pressure, regardless of the volume of fluid in the cylinder, until it is empty. (The pressure will decline somewhat as the cylinder is emptied due to the decline in weight of the remaining fluid.)

A working example of this type of accumulator may be found at the hydraulic engine house, Bristol Harbour.[2] The original 1887 accumulator is in place in its tower, an external accumulator was added in 1954 and this system was used until 2010 to power the Cumberland Basin (Bristol) lock gates. The water is pumped from the harbour into a header tank and then fed by gravity to the pumps. The working pressure is 750 psi (5.2 MPa, or 52 bar) which was used to power the cranes, bridges and locks of Bristol Harbour.[citation needed]

The original operating mechanism of Tower Bridge, London, also used this type of accumulator. Although no longer in use, two of the six accumulators may still be seen in situ in the bridge's museum.[original research?]

Regent's Canal Dock, now named Limehouse Basin has the remains of a hydraulic accumulator, dating from 1869, a fragment of the oldest remaining such facility in the world, the second at the dock, which was installed later than that at Poplar Dock, originally listed incorrectly as a signalbox for the London and Blackwall Railway, when correctly identified, it was restored as a tourist attraction by the now defunct London Docklands Development Corporation.[clarification needed] Now owned by the Canal & River Trust, it is open for large groups on application to the Dockmaster's Office at the basin and on both the afternoons of London Open House Weekend, held on the third weekend of September each year.[3]

London had an extensive public hydraulic power system from the mid-nineteenth century finally closing in the 1970s with 5 hydraulic power stations, operated by the London Hydraulic Power Company. Railway goods yards and docks often had their own separate system.[citation needed]

Air-filled accumulator[edit]

A simple form of accumulator is an enclosed volume, filled with air. A vertical section of pipe, often enlarged diameter, may be enough and fills itself with air, trapped as the pipework fills.

Such accumulators typically do not have enough capacity to be useful for storing significant power since they cannot be pre-charged with high pressure gas, but they can act as a buffer to absorb fluctuations in pressure. They are used to smooth out the delivery from piston pumps. Another use is as a shock absorber to damp out water hammer, this application is an integral part of most ram pumps. Loss of air will result in loss of effectiveness, if air will be lost over time the design must include some way to renew it.

Compressed gas (or gas-charged) closed accumulator[edit]

A compressed gas accumulator consists of a cylinder with two chambers that are separated by an elastic diaphragm, a totally enclosed bladder, or a floating piston. One chamber contains the fluid and is connected to the hydraulic line. The other chamber contains an inert gas (typically nitrogen), usually under pressure, that provides the compressive force on the hydraulic fluid. Inert gas is used because oxygen and oil can form an explosive mixture when combined under high pressure. As the volume of the compressed gas changes, the pressure of the gas (and the pressure on the fluid) changes inversely.

For low pressure water system use the water usually fills a rubber bladder within the tank (pictured), preventing contact with the tank which would otherwise need to be corrosion resistant. Units designed for high-pressure applications such as hydraulicsystems are usually pre-charged to a very high pressure (approaching the system operating pressure) and are designed to prevent the bladder or membrane being damaged by this internal pressure when the system pressure is low. For bladder types this generally requires the bladder to be filled with the gas so that when system pressure is zero the bladder is fully expanded rather than being crushed by the gas charge. To prevent the bladder being forced out of the device when the system pressure is low there is typically either an anti-extrusion plate attached to the bladder that presses against and seals the entrance, or a spring-loaded plate on the entrance that closes when the bladder presses against it.

It is possible to increase the gas volume of the accumulator by coupling a gas bottle to the gas side of the accumulator. For the same swing in system pressure this will result in a larger portion of the accumulator volume being used. If the pressure does not vary over a very wide range this can be a cost effective way to reduce the size of the accumulator needed. If the accumulator is not of the piston type care must be taken that the bladder or membrane will not be damaged in any expected over-pressure situation, many bladder-type accumulators cannot tolerate the bladder being crushed under pressure.

A compressed gas accumulator was invented by Jean Mercier[4] for use in variable-pitch propellers.

Spring type[edit]

A spring type accumulator is similar in operation to the gas-charged accumulator above, except that a heavy spring (or springs) is used to provide the compressive force. According to Hooke's law the magnitude of the force exerted by a spring is linearly proportional to its change of length. Therefore, as the spring compresses, the force it exerts on the fluid is increased linearly.

Metal bellows type[edit]

The metal bellows accumulators function similarly to the compressed gas type, except the elastic diaphragm or floating piston is replaced by a hermetically sealed welded metal bellows. Fluid may be internal or external to the bellows. The advantages to the metal bellows type include exceptionally low spring rate, allowing the gas charge to do all the work with little change in pressure from full to empty, a long stroke that allows efficient usage of the casing volume, and the bellows can be built to be resistant to significant over-pressure that would crush a bladder-type separator. The welded metal bellows accumulator provides an exceptionally high level of accumulator performance, and can be produced with a broad spectrum of alloys resulting in a broad range of fluid compatibility. Other advantages to this type are that it does not face issues with high pressure operation, may be built to be resistant to very high or low temperatures or certain aggressive chemicals, and may be significantly longer lasting in some situations. Metal bellows tend to be significantly more costly than other common types to produce.

Functioning of an accumulator[edit]

In modern, often mobile, hydraulic systems the preferred item is a gas charged accumulator, but simple systems may be spring-loaded. There may be more than one accumulator in a system. The exact type and placement of each may be a compromise[clarification needed] due to its effects and the costs of manufacture.

An accumulator is placed close to the pump with a non-return valve preventing flow back to the pump. In the case of piston-type pumps this accumulator is placed in the ideal location to absorb pulsations of energy from the multi-piston pump.[citation needed] It also helps protect the system from fluid hammer. This protects system components, particularly pipework, from both potentially destructive forces.

An additional benefit is the additional energy that can be stored while the pump is subject to low demand. The designer can use a smaller-capacity pump. The large excursions of system components, such as landing gear on a large aircraft, that require a considerable volume of fluid can also benefit from one or more accumulators. These are often placed close to the demand to help overcome restrictions and drag from long pipework runs. The outflow of energy from a discharging accumulator is much greater, for a short time, than even large pumps could generate.

An accumulator can maintain the pressure in a system for periods when there are slight leaks without the pump being cycled on and off constantly. When temperature changes cause pressure excursions the accumulator helps absorb them. Its size helps absorb fluid that might otherwise be locked in a small fixed system with no room for expansion due to valve arrangement.

The gas precharge in an accumulator is set so that the separating bladder, diaphragm or piston does not reach or strike either end of the operating cylinder. The design precharge normally ensures that the moving parts do not foul the ends or block fluid passages. Poor maintenance of precharge can destroy an operating accumulator. A properly designed and maintained accumulator should operate trouble-free for years.[citation needed]

See also[edit]

https://en.wikipedia.org/wiki/Hydraulic_accumulator

An accumulator is an energy storage device: a device which accepts energy, stores energy, and releases energy as needed. Some accumulators accept energy at a low rate (low power) over a long time interval and deliver the energy at a high rate (high power) over a short time interval. Some accumulators accept energy at a high rate over a short time interval and deliver the energy at a low rate over longer time interval. Some accumulators typically accept and release energy at comparable rates. Various devices can store thermal energy, mechanical energy, and electrical energy. Energy is usually accepted and delivered in the same form. Some devices store a different form of energy than what they receive and deliver performing energy conversion on the way in and on the way out.

Examples of accumulators include steam accumulators, mainsprings, flywheel energy storage, hydraulic accumulators, rechargeable batteries, capacitors, inductors, compensated pulsed alternators (compulsators), and pumped-storage hydroelectric plants.

In general usage in an electrical context, the word accumulator normally refers to a lead–acid battery.

The London Tower Bridge is operated via an accumulator. The original raising mechanism was powered by pressurised water stored in several hydraulic accumulators.[1] In 1974, the original operating mechanism was largely replaced by a new electro-hydraulic drive system.

https://en.wikipedia.org/wiki/Accumulator_(energy)

Pumped-storage hydroelectricity (PSH), or pumped hydroelectric energy storage (PHES), is a type of hydroelectric energy storage used by electric power systems for load balancing. The method stores energy in the form of gravitational potential energy of water, pumped from a lower elevation reservoir to a higher elevation. Low-cost surplus off-peak electric power is typically used to run the pumps. During periods of high electrical demand, the stored water is released through turbines to produce electric power. Although the losses of the pumping process make the plant a net consumer of energy overall, the system increases revenue by selling more electricity during periods of peak demand, when electricity prices are highest. If the upper lake collects significant rainfall or is fed by a river then the plant may be a net energy producer in the manner of a traditional hydroelectric plant.

Pumped-storage hydroelectricity allows energy from intermittent sources (such as solar, wind) and other renewables, or excess electricity from continuous base-load sources (such as coal or nuclear) to be saved for periods of higher demand.[1][2] The reservoirs used with pumped storage are quite small when compared to conventional hydroelectric dams of similar power capacity, and generating periods are often less than half a day.

Pumped storage is by far the largest-capacity form of grid energy storage available, and, as of 2020, the United States Department of Energy Global Energy Storage Database reports that PSH accounts for around 95% of all active tracked storage installations worldwide, with a total installed throughput capacity of over 181 GW, of which about 29 GW are in the United States, and a total installed storage capacity of over 1.6 TWh, of which about 250 GWh are in the United States.[3] The round-trip energy efficiency of PSH varies between 70%–80%,[4][5][6][7] with some sources claiming up to 87%.[8] The main disadvantage of PSH is the specialist nature of the site required, needing both geographical height and water availability. Suitable sites are therefore likely to be in hilly or mountainous regions, and potentially in areas of natural beauty, making PSH susceptible to social and ecological issues. Many recently proposed projects, at least in the U.S., avoid highly sensitive or scenic areas, and some propose to take advantage of "brownfield" locations such as disused mines.[9]

Home use[edit]

Using a pumped-storage system of cisterns and small generators, pico hydro may also be effective for "closed loop" home energy generation systems.[58][59]

Fracking[edit]

Using hydraulic fracturing pressure can be stored underground in strata such as shale. The shale used contains no hydrocarbons.[60]

See also[edit]

https://en.wikipedia.org/wiki/Pumped-storage_hydroelectricity

Compressed-air energy storage (CAES) is a way to store energy for later use using compressed air. At a utilityscale, energy generated during periods of low demand can be released during peak load periods.[1]

The first utility scale CAES project has been built in Huntorf, Germany, being still operational.[2] While the Huntorf CAES plant was initially developed as a load balancer for fossil fuel-generated electricity, the global shift towards renewable energy has led to a renewed interest in CAES systems,[3] to help highly intermittent energy sources like photovoltaics and wind satisfy fluctuating electricity demands.[4]

One ongoing challenge in large scale CAES design is the management of thermal energy since the compression of air leads to an unwanted temperature increase that not only reduces operational efficiency but can also lead to damage. The main difference between various CAES architectures lies in thermal engineering. On the other hand, small-scale systems have long been used as propulsion of mine locomotives. Compared to traditional batteries, CAES systems can store energy for longer periods of time and have less upkeep.

https://en.wikipedia.org/wiki/Compressed-air_energy_storage

A gravity battery is a type of electrical storage device that stores gravitational energy, the energy stored in an object resulting from a change in height due to gravity, also called potential energy. A gravity battery works by using excess energy from the grid to raise a mass to generate gravitational potential energy, which is then dropped to convert potential energy into electricity through an electric generator. Energy generated from a gravity battery is a form of sustainable energy. One form of a gravity battery is one that releases a mass, such as a block of concrete, to generate electricity. The most common gravity battery is used in pumped-storage hydroelectricity, where water is pumped to higher elevations to store energy and released through water turbines to generate electricity.[1]

Development[edit]

The earliest form of a device that used gravity to power mechanical movement was the pendulum clock, invented in 1656 by Christiaan Huygens. The clock was powered by the force of gravity using an escapement mechanism, that made a pendulum move back and forth. Since then, gravity batteries have advanced into systems that can harness the power of gravity and turn it into electricity for large scale energy storage.

The first gravity based pumped-storage hydroelectricity (PSH) system was developed in 1907 in Switzerland. In 1930, pumped-storage came to the United States by the Connecticut Electric and Power Company. As of 2019, the total world capacity for PSH is 168 GW (gigawatts).[2] The United States has 23 GW capacity from PSH, accounting for nearly 2% of the energy supply system and 95% of utility-scale energy storage in the US. Gravity based pumped-storage electricity is currently the largest form of grid energy storage in the world.[3][4][5][6]

In 2012, Martin Riddiford and Jim Reeves developed the first functioning prototype of GravityLight, a small-scale gravity battery that is now commercially available in certain countries.[7]

Energy Vault, an energy storage company, is also currently working on research and testing to develop gravity batteries on a larger scale. Founded by Bill Gross, Andewa Pedretti, and Robert Piconi in 2017, Energy Vault is currently in the midst of taking what GravityLight created to a larger scale. Energy Vault is developing a crane that generates electricity from dropping blocks of concrete rather than water. Energy Vault has not specified a release date for its product, but prototypes are in the works and Energy Vault’s stacked blocks concept is being built to be a promising long-duration storage technology.[8][9][10]In late 2020, the Swiss company built in Arbedo-Castione six cranes installed in a 110-meter-high tower moving a 35-ton concrete block up and down that can store 80 megawatt hours of energy.[11][12]

Cascadia Carbon Inc., a Portland, Oregon headquartered climate technology company, is also developing a potential energy battery for renewable grid stability in conjunction with University of British Columbia[citation needed]. Their pilot project aims to provide a commercial proof-of-concept which can be expanded to accommodate the gigawatts of new solar and wind storage which will be coming online over the next decade as the world begins to decarbonize the electrical grid.[13][unreliable source]

Gravitricity, another gravity battery company, is working on another approach to a new energy storage system. Founded in 2011 by inventor Peter Fraenkel, Gravitricity built a 10 meter 250 kilowatt gravity battery prototype in Scotland that started trial operations and grid-connection in 2021.[14][15][16] In April 2021, Gravitricity had installed a gravity battery which generated its first power at a site in Edinburgh.[17]

Mechanisms and parts[edit]

Gravity batteries can have different designs and structures, but all gravity batteries use the same properties of physics to generate energy. Gravitational potential energy is the work required to move an object in the opposite direction of Earth's gravity, expressed by the equation

where U is gravitational potential energy, m is the mass of the object, g is the acceleration of the object due to gravity (9.8 m/s on earth), and h is the height of the object. Using the work-energy principle, the total amount of energy generated can be expressed by the equation

where E is the total amount of energy generated and h1 and h2 represent the initial and final heights of an object. The change of energy directly correlates to the vertical displacement of a mass; the higher a mass is lifted, the more gravitational potential energy is stored. The change in energy also directly correlates to the mass of an object; the heavier the mass, the bigger the change in energy.

In a gravity battery, a mass is displaced, or lifted, to generate gravitational potential energy that is transformed into electricity. Gravity batteries store gravitational potential energy by lifting a mass to a certain height using a pump, crane, or motor. After the mass is lifted, it now stores a certain gravitational potential energy based on the mass of the object and how high it was lifted. The stored gravitational potential energy is then transferred into electricity. The mass is lowered or released to fall back to its original height, which causes a generator to spin and create electricity.

Types of gravity batteries[edit]

One structure of a gravity battery uses a very tall structure with a heavy mass. This tall structure can be built above ground, such as a tall building or tower, or a deep hole can be drilled into earth's surface to a certain depth necessary for the battery to meet specifications. A mass is lifted to the top of the tower, or the top of the hole, using a system of pulleys. Energy is needed to lift the mass, but this energy is usually surplus energy that is used during times when energy production is greater than the demand. When the surplus energy runs out, the mass is then dropped to generate electricity through the generator.[18]

Large scale[edit]

Lifted Weight Storage (LWS) technology is developed by Energozapas company. LWS operational principle is based on consuming electricity while lifting weights vertically in respect to the Earth’s gravitational field (several hundred meters high) and generating energy when released weights go down due to the gravity force. Solid blocks made of pressed soil act as weights. Load bearing structure is a reinforced concrete construction, built with the help of construction robots. Energozapas technology enables to build industrial scale energy storages starting with 10MW in power. Storage lifetime is 50 years, roundtrip efficiency is 83%.[19]

Lift Renewable Energy uses a form of gravity battery. To store energy, buoyant gas containers are pulled down into water by a winch, water is in effect lifted hundreds of meters. The cycle is then reversed and electricity is generated as the gas containers rise. Relatively little infrastructure is required, the batteries can be sited near major population centers and round trip efficiency is 85+%. The system can be scaled from KWH's to GWH's. https://lift-re.com/

EnergyVault is working on developing large scale gravity batteries. The gravity battery they are working on developing is an energy storage tower built from concrete blocks. 120 meter cranes use excess energy from the electric grid to lift and stack concrete blocks, each weighing 32 metric tons. Energy is retrieved when bricks fall to generate energy by turning a generator. One commercial unit can store 20 MWh or energy, or enough to power 2,000 Swiss homes a day.[9]

Gravitricity's gravity battery unit consists of a convertible electric winch/generator, cables, a large weight, and vertical shaft going 150 to 1500 meters underground using disused mine shafts initially. The electric winch lifts a weight weighing from 500 to 5000 tonnes to the top of the shaft. When weight is released, it rotates the electric winch within a magnetic field to generate energy. The system generates 10 MWh, enough power for 13,000 homes for two hours. The battery can also be controlled to drop the weight quickly for a small burst of high-power energy.[14]

Another form of a gravity battery is pumped-storage hydroelectricity (PSH), the largest form of grid-energy storage. PSH uses water instead of a solid mass, which is pumped from a lower reservoir to a higher reservoir before being released through turbines to create energy. An alternative proposal uses a proprietary high-density liquid, 21⁄2 times denser than water, which requires a smaller head (elevation) and thus decreases the size and cost of the necessary infrastructure.[20][21]

Energy-storage-by-rail is a concept where excess renewable energy is used to run heavy trains cars uphill during times of low energy demand. The potential energy is release later by using regenerative braking as they roll downhill, acting as a gravity battery.[22] A utility-scale facility called GravityLine began construction in Nevada in October 2020. GravityLine is being constructed by Advanced Rail Energy Storage (ARES) located at the Gamebird Pit gravel mine in the Pahrump Valley, Nevada. The 50-MW facility is expected to store excess renewable energy from Western U.S. sources and deliver up to 15 minutes of regulation services at full capacity.[23]

Small scale[edit]

GravityLight is a small gravity-powered light that operates by manually lifting a bag of rocks or sand up and then letting it fall by itself to generate energy. The GravityLight was designed to help the almost one billion people in the world who do not have a source of electricity, as it would eliminate the need for people who do not have access to electricity to rely on kerosene lamps, which are expensive, dangerous, and polluting.[7][24][25]

Economics and efficiency[edit]

Cost of gravity batteries varies by design.

Pumped storage hydropower costs $165/kWh to operate, with a levelized cost of storage (LCOS), of $0.17/kWh.[26][27] The pumps and turbines of PSH systems operate at 90% efficiency.[28]

EnergyVault's proposed gravity battery system range from 7 to 8 million in building price but has a LCOS of $0.05/kWh and a round-trip efficiency of 88–92%. This is 50% cheaper when compared to the LCOS of lithium-ion batteries, which are $0.25/kWh-$0.35/kWh.[29]

Gravitricity's 250 kW demonstrator is expected to be $1.25 million, promising a 50-year lifespan and efficiency of 80–90%. Relative costs of gravity storage installations that would use 2000-tonne weights suspended from winches in disused mineshafts, compared with lithium ion batteries, indicate that although the "up front cost is high" the 25-year lifespan of such equipment—with no degradation of capacity during use—makes a "compelling proposition" for large-scale grid balancing purposes.[30]

Unlike pumped-storage hydroelectricity, solar panels, and wind turbines, which can only operate under certain conditions or in certain areas, gravity batteries like those proposed by EnergyVault and Gravitricity can be built anywhere in the world and use materials from the building site.[18][31]

Environmental impacts[edit]

Gravity batteries are designed to be paired with renewable energy solutions whose sources (sunlight, wind, etc) are frequently variable and do not necessarily coincide with demand. It is hoped that they will have a better long term cost than chemical batteries, while having fewer environmental issues than other traditional storage solutions such as pumped-water storage. It is anticipated that gravity battery systems will be able to quickly provide power during peak consumption which may allow them to supplement or replace fossil fuel peaking power plants. Single weight systems are expected to be able to achieve full power generation in less than a second.[15]

Implementing gravity batteries on a larger scale would therefore decrease the need for fossil fuels, significantly cutting down CO2 emissions.[citation needed]

Gravity batteries are more environmentally friendly than lithium-ion batteries, since lithium-ion batteries have a shorter lifetime and problems arise when they need to be disposed of.[1]

Gravity (chemical) battery[edit]

From 1870 to 1930,[32] the term "gravity battery" was used to describe a collection of popular battery types where gravity was used to keep the chemical constituents separate based on their respective densities.[33]

See also[edit]

https://en.wikipedia.org/wiki/Gravity_battery

Geothermal power is electrical power generated from geothermal energy. Technologies in use include dry steam power stations, flash steam power stations and binary cycle power stations. Geothermal electricity generation is currently used in 26 countries,[1][2] while geothermal heating is in use in 70 countries.[3]

As of 2019, worldwide geothermal power capacity amounts to 15.4 gigawatts (GW), of which 23.86 percent or 3.68 GW are installed in the United States.[4] International markets grew at an average annual rate of 5 percent over the three years to 2015, and global geothermal power capacity is expected to reach 14.5–17.6 GW by 2020.[5] Based on current geologic knowledge and technology the GEA publicly discloses, the Geothermal Energy Association (GEA) estimates that only 6.9 percent of total global potential has been tapped so far, while the IPCC reported geothermal power potential to be in the range of 35 GW to 2 TW.[3] Countries generating more than 15 percent of their electricity from geothermal sources include El Salvador, Kenya, the Philippines, Iceland, New Zealand,[6] and Costa Rica.

Geothermal power is considered to be a sustainable, renewable source of energy because the heat extraction is small compared with the Earth's heat content.[7] The greenhouse gas emissions of geothermal electric stations are on average 45 grams of carbon dioxide per kilowatt-hour of electricity, or less than 5 percent of that of conventional coal-fired plants.[8]

As a source of renewable energy for both power and heating, geothermal has the potential to meet 3-5% of global demand by 2050. With economic incentives, it is estimated that by 2100 it will be possible to meet 10% of global demand.[6]

https://en.wikipedia.org/wiki/Geothermal_power

Cyclic stress is the distribution of forces (aka stresses) that change over time in a repetitive fashion. As an example, consider one of the large wheels used to drive an aerial lift such as a ski lift. The wire cable wrapped around the wheel exerts a downward force on the wheel and the drive shaft supporting the wheel. Although the shaft, wheel, and cable move, the force remains nearly vertical relative to the ground. Thus a point on the surface of the drive shaft will undergo tension when it is pointing towards the ground and compression when it is pointing to the sky.

Types of cyclic stress[edit]

Cyclic stress is frequently encountered in rotating machinery where a bending moment is applied to a rotating part. This is called a cyclic bending stress and the aerial lift above is a good example. However, cyclic axial stresses and cyclic torsional stresses also exist. An example of cyclic axial stress would be a bungee cord (see bungee jumping), which must support the mass of people as they jump off structures such as bridges. When a person reaches the end of a cord, the cord deflects elastically and stops the person's descent. This creates a large axial stress in the cord. A fraction of the elastic potential energy stored in the cord is typically transferred back to the person, throwing the person upwards some fraction of the distance he or she fell. The person then falls on the cord again, inducing stress in the cord. This happens multiple times per jump. The same cord is used for several jumps, creating cyclical stresses in the cord that could eventually cause failure if not replaced.

Cyclic stress and material failure[edit]

When cyclic stresses are applied to a material, even though the stresses do not cause plastic deformation, the material may fail due to fatigue. Fatigue failure is typically modeled by decomposing cyclic stresses into mean and alternating components. Mean stress is the time average of the principal stress. The definition of alternating stress varies between different sources. It is either defined as the difference between the minimum and the maximum stress, or the difference between the mean and maximum stress.[1][2] Engineers try to design mechanisms whose parts are subjected to a single type (bending, axial, or torsional) of cyclic stress because this more closely matches experiments used to characterize fatigue failure in different materials.

https://en.wikipedia.org/wiki/Cyclic_stress

A polarization rotator is an optical device that rotates the polarization axis of a linearly polarized light beam by an angle of choice. Such devices can be based on the Faraday effect, on birefringence, or on total internal reflection.[1] Rotators of linearly polarized light have found widespread applications in modern optics since laser beams tend to be linearly polarized and it is often necessary to rotate the original polarization to its orthogonal alternative.[1]

https://en.wikipedia.org/wiki/Polarization_rotator

Ferroelectricity is a characteristic of certain materials that have a spontaneous electric polarization that can be reversed by the application of an external electric field.[1][2] All ferroelectrics are pyroelectric, with the additional property that their natural electrical polarization is reversible. The term is used in analogy to ferromagnetism, in which a material exhibits a permanent magnetic moment. Ferromagnetism was already known when ferroelectricity was discovered in 1920 in Rochelle salt by Valasek.[3] Thus, the prefix ferro, meaning iron, was used to describe the property despite the fact that most ferroelectric materials do not contain iron. Materials that are both ferroelectric and ferromagnetic are known as multiferroics.

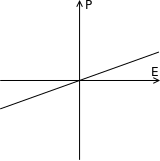

Polarization[edit]

When most materials are electrically polarized, the polarization induced, P, is almost exactly proportional to the applied external electric field E; so the polarization is a linear function. This is called linear dielectric polarization (see figure). Some materials, known as paraelectric materials,[4] show a more enhanced nonlinear polarization (see figure). The electric permittivity, corresponding to the slope of the polarization curve, is not constant as in linear dielectrics but is a function of the external electric field.

In addition to being nonlinear, ferroelectric materials demonstrate a spontaneous nonzero polarization (after entrainment, see figure) even when the applied field E is zero. The distinguishing feature of ferroelectrics is that the spontaneous polarization can be reversed by a suitably strong applied electric field in the opposite direction; the polarization is therefore dependent not only on the current electric field but also on its history, yielding a hysteresis loop. They are called ferroelectrics by analogy to ferromagnetic materials, which have spontaneous magnetization and exhibit similar hysteresis loops.

Typically, materials demonstrate ferroelectricity only below a certain phase transition temperature, called the Curie temperature (TC) and are paraelectric above this temperature: the spontaneous polarization vanishes, and the ferroelectric crystal transforms into the paraelectric state. Many ferroelectrics lose their pyroelectric properties above TC completely, because their paraelectric phase has a centrosymmetric crystal structure.[5]

Applications[edit]

The nonlinear nature of ferroelectric materials can be used to make capacitors with adjustable capacitance. Typically, a ferroelectric capacitor simply consists of a pair of electrodes sandwiching a layer of ferroelectric material. The permittivity of ferroelectrics is not only adjustable but commonly also very high, especially when close to the phase transition temperature. Because of this, ferroelectric capacitors are small in physical size compared to dielectric (non-tunable) capacitors of similar capacitance.

The spontaneous polarization of ferroelectric materials implies a hysteresis effect which can be used as a memory function, and ferroelectric capacitors are indeed used to make ferroelectric RAM[6] for computers and RFID cards. In these applications thin films of ferroelectric materials are typically used, as this allows the field required to switch the polarization to be achieved with a moderate voltage. However, when using thin films a great deal of attention needs to be paid to the interfaces, electrodes and sample quality for devices to work reliably.[7]

Ferroelectric materials are required by symmetry considerations to be also piezoelectric and pyroelectric. The combined properties of memory, piezoelectricity, and pyroelectricity make ferroelectric capacitors very useful, e.g. for sensor applications. Ferroelectric capacitors are used in medical ultrasound machines (the capacitors generate and then listen for the ultrasound ping used to image the internal organs of a body), high quality infrared cameras (the infrared image is projected onto a two dimensional array of ferroelectric capacitors capable of detecting temperature differences as small as millionths of a degree Celsius), fire sensors, sonar, vibration sensors, and even fuel injectors on diesel engines.

Another idea of recent interest is the ferroelectric tunnel junction (FTJ) in which a contact is made up by nanometer-thick ferroelectric film placed between metal electrodes.[8] The thickness of the ferroelectric layer is small enough to allow tunneling of electrons. The piezoelectric and interface effects as well as the depolarization field may lead to a giant electroresistance (GER) switching effect.

Yet another burgeoning application is multiferroics, where researchers are looking for ways to couple magnetic and ferroelectric ordering within a material or heterostructure; there are several recent reviews on this topic.[9]

Catalytic properties of ferroelectrics have been studied since 1952 when Parravano observed anomalies in CO oxidation rates over ferroelectric sodium and potassium niobates near the Curie temperature of these materials.[10] Surface-perpendicular component of the ferroelectric polarization can dope polarization-dependent charges on surfaces of ferroelectric materials, changing their chemistry.[11][12][13] This opens the possibility of performing catalysis beyond the limits of the Sabatier principle.[14] Sabatier principle states that the surface-adsorbates interaction has to be an optimal amount: not too weak to be inert toward the reactants and not too strong to poison the surface and avoid desorption of the products: a compromise situation.[15] This set of optimum interactions is usually referred to as "top of the volcano" in activity volcano plots.[16] On the other hand, ferroelectric polarization-dependent chemistry can offer the possibility of switching the surface—adsorbates interaction from strong adsorption to strong desorption, thus a compromise between desorption and adsorption is no longer needed.[14] Ferroelectric polarization can also act as an energy harvester.[17] Polarization can help the separation of photo-generated electron-hole pairs, leading to enhanced photocatalysis.[18] Also, due to pyroelectric and piezoelectric effects under varying temperature (heating/cooling cycles)[19][20] or varying strain (vibrations) conditions[21] extra charges can appear on the surface and drive various (electro)chemical reactions forward.

Materials[edit]

The internal electric dipoles of a ferroelectric material are coupled to the material lattice so anything that changes the lattice will change the strength of the dipoles (in other words, a change in the spontaneous polarization). The change in the spontaneous polarization results in a change in the surface charge. This can cause current flow in the case of a ferroelectric capacitor even without the presence of an external voltage across the capacitor. Two stimuli that will change the lattice dimensions of a material are force and temperature. The generation of a surface charge in response to the application of an external stress to a material is called piezoelectricity. A change in the spontaneous polarization of a material in response to a change in temperature is called pyroelectricity.

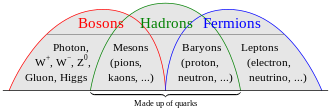

Generally, there are 230 space groups among which 32 crystalline classes can be found in crystals. There are 21 non-centrosymmetric classes, within which 20 are piezoelectric. Among the piezoelectric classes, 10 have a spontaneous electric polarization, that varies with the temperature, therefore they are pyroelectric. Among pyroelectric materials, some of them are ferroelectric.[citation needed]

| 32 Crystalline classes | ||||

|---|---|---|---|---|

| 21 noncentrosymmetric | 11 centrosymmetric | |||

| 20 classes piezoelectric | non piezoelectric | |||

| 10 classes pyroelectric | non pyroelectric | |||

| ferroelectric | non ferroelectric | |||

| e.g. : PbZr/TiO3, BaTiO3, PbTiO3 | e.g. : Tourmaline, ZnO, AlN | e.g. : Quartz, Langasite | ||

Ferroelectric phase transitions are often characterized as either displacive (such as BaTiO3) or order-disorder (such as NaNO2), though often phase transitions will demonstrate elements of both behaviors. In barium titanate, a typical ferroelectric of the displacive type, the transition can be understood in terms of a polarization catastrophe, in which, if an ion is displaced from equilibrium slightly, the force from the local electric fields due to the ions in the crystal increases faster than the elastic-restoring forces. This leads to an asymmetrical shift in the equilibrium ion positions and hence to a permanent dipole moment. The ionic displacement in barium titanate concerns the relative position of the titanium ion within the oxygen octahedral cage. In lead titanate, another key ferroelectric material, although the structure is rather similar to barium titanate the driving force for ferroelectricity is more complex with interactions between the lead and oxygen ions also playing an important role. In an order-disorder ferroelectric, there is a dipole moment in each unit cell, but at high temperatures they are pointing in random directions. Upon lowering the temperature and going through the phase transition, the dipoles order, all pointing in the same direction within a domain.

An important ferroelectric material for applications is lead zirconate titanate (PZT), which is part of the solid solution formed between ferroelectric lead titanate and anti-ferroelectric lead zirconate. Different compositions are used for different applications; for memory applications, PZT closer in composition to lead titanate is preferred, whereas piezoelectric applications make use of the diverging piezoelectric coefficients associated with the morphotropic phase boundary that is found close to the 50/50 composition.

Ferroelectric crystals often show several transition temperatures and domain structure hysteresis, much as do ferromagnetic crystals. The nature of the phase transition in some ferroelectric crystals is still not well understood.

In 1974 R.B. Meyer used symmetry arguments to predict ferroelectric liquid crystals,[22] and the prediction could immediately be verified by several observations of behavior connected to ferroelectricity in smectic liquid-crystal phases that are chiral and tilted. The technology allows the building of flat-screen monitors. Mass production between 1994 and 1999 was carried out by Canon. Ferroelectric liquid crystals are used in production of reflective LCoS.

In 2010 David Field found that prosaic films of chemicals such as nitrous oxide or propane exhibited ferroelectric properties.[citation needed] This new class of ferroelectric materials exhibit "spontelectric" properties, and may have wide-ranging applications in device and nano-technology and also influence the electrical nature of dust in the interstellar medium.

Other ferroelectric materials used include triglycine sulfate, polyvinylidene fluoride (PVDF) and lithium tantalate.[23]

It should be possible to produce materials which combine both ferroelectric and metallic properties simultaneously, at room temperature.[24] According to research published in 2018 in Nature Communications,[25] scientists were able to produce a "two-dimensional" sheet of material which was both "ferroelectric" (had a polar crystal structure) and which conducted electricity.

See also[edit]

Physics | Lists |

https://en.wikipedia.org/wiki/Ferroelectricity

Curing[edit]

Concrete must be kept moist during curing in order to achieve optimal strength and durability.[65] During curing hydration occurs, allowing calcium-silicate hydrate (C-S-H) to form. Over 90% of a mix's final strength is typically reached within four weeks, with the remaining 10% achieved over years or even decades.[66] The conversion of calcium hydroxide in the concrete into calcium carbonate from absorption of CO2 over several decades further strengthens the concrete and makes it more resistant to damage. This carbonation reaction, however, lowers the pH of the cement pore solution and can corrode the reinforcement bars.

Hydration and hardening of concrete during the first three days is critical. Abnormally fast drying and shrinkage due to factors such as evaporation from wind during placement may lead to increased tensile stresses at a time when it has not yet gained sufficient strength, resulting in greater shrinkage cracking. The early strength of the concrete can be increased if it is kept damp during the curing process. Minimizing stress prior to curing minimizes cracking. High-early-strength concrete is designed to hydrate faster, often by increased use of cement that increases shrinkage and cracking. The strength of concrete changes (increases) for up to three years. It depends on cross-section dimension of elements and conditions of structure exploitation.[67] Addition of short-cut polymer fibers can improve (reduce) shrinkage-induced stresses during curing and increase early and ultimate compression strength.[68]

Properly curing concrete leads to increased strength and lower permeability and avoids cracking where the surface dries out prematurely. Care must also be taken to avoid freezing or overheating due to the exothermic setting of cement. Improper curing can cause scaling, reduced strength, poor abrasionresistance and cracking.

https://en.wikipedia.org/wiki/Concrete#Curing

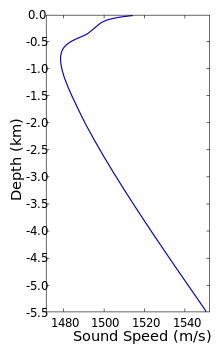

Methane clathrate (CH4·5.75H2O) or (4CH4·23H2O), also called methane hydrate, hydromethane, methane ice, fire ice, natural gas hydrate, or gas hydrate, is a solid clathrate compound (more specifically, a clathrate hydrate) in which a large amount of methane is trapped within a crystal structure of water, forming a solid similar to ice.[1][2][3][4] Originally thought to occur only in the outer regions of the Solar System, where temperatures are low and water ice is common, significant deposits of methane clathrate have been found under sediments on the ocean floors of the Earth.[5] Methane hydrate is formed when hydrogen-bonded water and methane gas come into contact at high pressures and low temperatures in oceans.

Methane clathrates are common constituents of the shallow marine geosphere and they occur in deep sedimentary structures and form outcrops on the ocean floor. Methane hydrates are believed to form by the precipitation or crystallisation of methane migrating from deep along geological faults. Precipitation occurs when the methane comes in contact with water within the sea bed subject to temperature and pressure. In 2008, research on Antarctic Vostok Station and EPICA Dome C ice cores revealed that methane clathrates were also present in deep Antarctic ice cores and record a history of atmospheric methane concentrations, dating to 800,000 years ago.[6] The ice-core methane clathrate record is a primary source of data for global warmingresearch, along with oxygen and carbon dioxide.

https://en.wikipedia.org/wiki/Methane_clathrate

Atmospheric methane is the methane present in Earth's atmosphere.[3] Atmospheric methane concentrations are of interest because it is one of the most potent greenhouse gases in Earth's atmosphere. Atmospheric methane is rising.[4]

The 20-year global warming potential of methane is 84.[5][6] That is, over a 20-year period, it traps 84 times more heat per mass unit than carbon dioxide (CO2) and 105 times the effect when accounting for aerosol interactions.[7] Global methane concentrations rose from 722 parts per billion (ppb) in pre-industrial times to 1879 ppb by 2020,[8] an increase by a factor of 2.5 and the highest value in at least 800,000 years.[9] Its concentration is higher in the Northern Hemisphere since most sources (both natural and human) are located on land and the Northern Hemisphere has more land mass.[10] The concentrations vary seasonally, with, for example, a minimum in the northern tropics during April−May mainly due to removal by the hydroxyl radical.[11] It remains in the atmosphere for 12 years.[12]

Early in the Earth's history carbon dioxide and methane likely produced a greenhouse effect. The carbon dioxide would have been produced by volcanoes and the methane by early microbes. During this time, Earth's earliest life appeared.[13] These first, ancient bacteria added to the methane concentration by converting hydrogen and carbon dioxide into methane and water. Oxygen did not become a major part of the atmosphere until photosynthetic organisms evolved later in Earth's history. With no oxygen, methane stayed in the atmosphere longer and at higher concentrations than it does today.[14]

https://en.wikipedia.org/wiki/Atmospheric_methane

A greenhouse gas (GHG or GhG) is a gas that absorbs and emits radiant energy within the thermal infrared range, causing the greenhouse effect.[1] The primary greenhouse gases in Earth's atmosphereare water vapor (H

2O), carbon dioxide (CO

2), methane (CH

4), nitrous oxide (N

2O), and ozone (O3). Without greenhouse gases, the average temperature of Earth's surface would be about −18 °C (0 °F),[2] rather than the present average of 15 °C (59 °F).[3][4][5] The atmospheres of Venus, Mars and Titan also contain greenhouse gases.

Human activities since the beginning of the Industrial Revolution (around 1750) have increased the atmospheric concentration of carbon dioxide by almost 50%, from 280 ppm in 1750 to 419 ppm in 2021.[6] The last time the atmospheric concentration of carbon dioxide was this high was over 3 million years ago.[7] This increase has occurred despite the absorption of more than half of the emissions by various natural carbon sinks in the carbon cycle.[8][9]

At current greenhouse gas emission rates, temperatures could increase by 2 °C (3.6 °F), which the United Nations' Intergovernmental Panel on Climate Change (IPCC) says is the upper limit to avoid "dangerous" levels, by 2050.[10] The vast majority of anthropogenic carbon dioxide emissions come from combustion of fossil fuels, principally coal, petroleum (including oil) and natural gas, with additional contributions from deforestation and other changes in land use.[11][12]

https://en.wikipedia.org/wiki/Greenhouse_gas

In thermodynamics, dissipation is the result of an irreversible process that takes place in homogeneous thermodynamic systems. In a dissipative process, energy (internal, bulk flow kinetic, or system potential) transforms from an initial form to a final form, where the capacity of the final form to do mechanical work is less than that of the initial form. For example, heat transfer is dissipative because it is a transfer of internal energy from a hotter body to a colder one. Following the second law of thermodynamics, the entropy varies with temperature (reduces the capacity of the combination of the two bodies to do mechanical work), but never decreases in an isolated system.

These processes produce entropy at a certain rate. The entropy production rate times ambient temperature gives the dissipated power. Important examples of irreversible processes are: heat flow through a thermal resistance, fluid flow through a flow resistance, diffusion (mixing), chemical reactions, and electrical current flow through an electrical resistance (Joule heating).

https://en.wikipedia.org/wiki/Dissipation

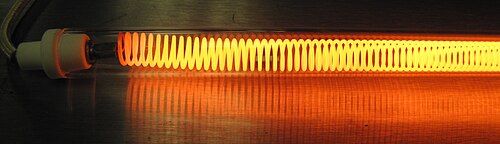

Joule heating, also known as resistive, resistance, or Ohmic heating, is the process by which the passage of an electric currentthrough a conductor produces heat.

Joule's first law (also just Joule's law), also known as the Joule–Lenz law,[1] states that the power of heating generated by an electrical conductor is proportional to the product of its resistance and the square of the current:

Joule heating affects the whole electric conductor, unlike the Peltier effect which transfers heat from one electrical junction to another.

https://en.wikipedia.org/wiki/Joule_heating

In electricity supply design, a ring final circuit or ring circuit (often incorrectly called a ring main, a term used historically,[1] or informally a ring) is an electrical wiring technique developed and primarily used in the United Kingdom, and to a lesser extent in Ireland and Hong Kong. This design enables the use of smaller-diameter wire than would be used in a radial circuit of equivalent total current. The reduced diameter conductors in the flexible cords connecting an appliance to the plug intended for use with sockets on a ring circuit are individually protected by a fuse in the plug. Its advantages over radial circuits are therefore reduced quantity of copper used, and greater flexibility of appliances and equipment that can be connected.

Ideally, the ring circuit acts like two radial circuits proceeding in opposite directions around the ring, the dividing point between them dependent on the distribution of load in the ring. If the load is evenly split across the two directions, the current in each direction is half of the total, allowing the use of wire with half the total current-carrying capacity. In practice, the load does not always split evenly, so thicker wire is used.

https://en.wikipedia.org/wiki/Ring_circuit

Mineral-insulated copper-clad cable is a variety of electrical cable made from copper conductors inside a copper sheath, insulated by inorganic magnesium oxide powder. The name is often abbreviated to MICC or MI cable, and colloquially known as pyro (because the original manufacturer and vendor for this product in the UK was a company called Pyrotenax). A similar product sheathed with metals other than copper is called mineral insulated metal sheathed (MIMS) cable.

MI cable is made by placing copper rods inside a circular copper tube and filling the intervening spaces with dry magnesium oxide powder. The overall assembly is then pressed between rollers to reduce its diameter (and increase its length). Up to seven conductors are often found in an MI cable, with up to 19 available from some manufacturers.

Since MI cables use no organic material as insulation (except at the ends), they are more resistant to fires than plastic-insulated cables. MI cables are used in critical fire protection applications such as alarm circuits, fire pumps, and smoke control systems. In process industries handling flammable fluids MI cable is used where small fires would otherwise cause damage to control or power cables. MI cable is also highly resistant to ionizing radiation and so finds applications in instrumentation for nuclear reactors and nuclear physics apparatus.

MI cables may be covered with a plastic sheath, coloured for identification purposes. The plastic sheath also provides additional corrosion protection for the copper sheath.

The metal tube shields the conductors from electromagnetic interference. The metal sheath also physically protects the conductors, most importantly from accidental contact with other energised conductors.

Purpose and use[edit]

MI cables are used for power and control circuits of critical equipment, such as the following examples:

- Nuclear reactors

- Exposure to dangerous gasses

- Air pressurisation systems for stairwells to enable building egress during a fire

- Hospital operating rooms

- Fire alarm systems

- Emergency power systems

- Emergency lighting systems

- Temperature measurement devices; RTDs and Thermocouples.

- Critical process valves in the petrochemical industry

- Public buildings such as theatres, cinemas, hotels

- Transport hubs (railway stations, airports etc.)

- Mains supply cables within residential apartment blocks

- Tunnels and mines

- Electrical equipment in hazardous areas where flammable gases may be present e.g. oil refineries, petrol stations

- Areas where corrosive chemicals may be present e.g. factories

- Building plant rooms

- Hot areas e.g. power stations, foundries, and close to or even inside industrial furnaces, kilns and ovens

MI cable fulfills the passive fire protection called circuit integrity, which is intended to provide operability of critical electrical circuits during a fire. It is subject to strict listing and approval use and compliance

https://en.wikipedia.org/wiki/Mineral-insulated_copper-clad_cable

Electric heat tracing, heat tape or surface heating, is a system used to maintain or raise the temperature of pipes and vessels using heat tracing cables. Trace heating takes the form of an electrical heating element run in physical contact along the length of a pipe. The pipe is usually covered with thermal insulation to retain heat losses from the pipe. Heat generated by the element then maintains the temperature of the pipe. Trace heating may be used to protect pipes from freezing, to maintain a constant flow temperature in hot water systems, or to maintain process temperatures for piping that must transport substances that solidify at ambient temperatures. Electric trace heating cables are an alternative to steam trace heating where steam is unavailable or unwanted.[2]

Anti-cavitation purpose[edit]

As heating a thick fluid decreases its viscosity, it reduces losses occurring in a pipe. Therefore, the net positive suction head (pressure difference) available can be raised, decreasing the likelihood of cavitation when pumping. However, care must be taken not to increase the vapour pressure of the fluid too much, as this would have a strong side effect on the available head, possibly outweighing any benefit.[7]

Constant electric power "series"[edit]

A series heating cable is made of a run of high-resistance wire, insulated and often enclosed in a protective jacket. It is powered at a specific voltage and the resistance heat of the wire creates heat. The downside of these types of heaters is that if they are crossed over themselves they can overheat and burn out, they are provided in specific lengths and cannot be shortened in the field, also, a break anywhere along the line will result in a failure of the entire cable. The upside is that they are typically inexpensive (if plastic style heaters) or, as is true with mineral insulated heating cables, they can be exposed to very high temperatures. Mineral insulated heating cables are good for maintaining high temperatures on process lines or maintaining lower temperatures on lines which can get extremely hot such as high temperature steam lines.

Typically series elements are used on long pipe line process heating, for example long oil pipe lines and quay side of load pipes on oil refineries.

https://en.wikipedia.org/wiki/Trace_heating

The word electrofusion is also used when fusing cells with electricity.

Electrofusion is a method of joining MDPE, HDPE and other plastic pipes using special fittings that have built-in electric heating elements which are used to weld the joint together.

The pipes to be joined are cleaned, inserted into the electrofusion fitting (with a temporary clamp if required) and a voltage (typically 40V) is applied for a fixed time depending on the fitting in use. The built in heater coils then melt the inside of the fitting and the outside of the pipe wall, which weld together producing a very strong homogeneous joint. The assembly is then left to cool for a specified time.[1]

Electrofusion welding is beneficial because it does not require the operator to use dangerous or sophisticated equipment. After some preparation, the Electrofusion Welder will guide the operator through the steps to take. Welding Heat and Time is dependent on the type and size of the fitting. All Electrofusion Fittings are not created equal - Precise positioning of the energising coils of wire in each fitting ensures uniform melting for a strong joint and the minimisation of welding and cooling time.[2]

The operator must be qualified according to the local and national laws. In Australia, an Electrofusion Course can be done within 8 hours. Electrofusion welding training focuses on the importance of accurately fusing EF fittings. Both manual and automatic methods of calculating electrofusion time gives operators the skills they need in the field. There is much to learn about the importance of preparation, timing, pressure, temperature, cool down time and handling, etc.[3]

Training and certification are very important in this field of welding, as the product can become dangerous under certain circumstances. There has been cases of major harm and death, including when molten polyethylene spurts out of the edge of a mis-aligned weld, causing skin burns. Another case was due to a tapping saddle being incorrectly installed on a gas line, causing the death of the two welders in the trench due to gas inhalation. There are many critical parts to Electrofusion welding that can cause weld failures, most of which can be greatly reduced by using welding clamps, and correct scraping equipment.[4]

To keep their qualification current, a trained operator can get their fitting tested, which involves cutting open the fitting and examining the integrity of the weld.[5]

https://en.wikipedia.org/wiki/Electrofusion

https://en.wikipedia.org/wiki/Fanning_friction_factor

https://en.wikipedia.org/wiki/Threaded_pipe

https://en.wikipedia.org/wiki/Category:Piping

https://en.wikipedia.org/wiki/Friction_loss

https://en.wikipedia.org/wiki/Hydrogen_pipeline_transport

https://en.wikipedia.org/wiki/Iron_pipe_size

https://en.wikipedia.org/wiki/Heat-shrinkable_sleeve

https://en.wikipedia.org/wiki/Coupling_(piping)

https://en.wikipedia.org/wiki/Closet_flange

https://en.wikipedia.org/wiki/Drag_reducing_agent

https://en.wikipedia.org/wiki/Turbulence

https://en.wikipedia.org/wiki/Laminar_flow

https://en.wikipedia.org/wiki/Polymers

https://en.wikipedia.org/wiki/Suspension_(chemistry)

https://en.wikipedia.org/wiki/Surfactant

https://en.wikipedia.org/wiki/Pipe_bursting

https://en.wikipedia.org/wiki/Pipe_drift