A magnetohydrodynamic generator (MHD generator) is a magnetohydrodynamic converter that utilizes a Brayton cycle to transform thermal energy and kinetic energy directly into electricity. MHD generators are different from traditional electric generators in that they operate without moving parts (e.g. no turbine) to limit the upper temperature. They therefore have the highest known theoretical thermodynamic efficiency of any electrical generation method. MHD has been extensively developed as a topping cycle to increase the efficiency of electric generation, especially when burning coal or natural gas. The hot exhaust gas from an MHD generator can heat the boilers of a steam power plant, increasing overall efficiency.

An MHD generator, like a conventional generator, relies on moving a conductor through a magnetic field to generate electric current. The MHD generator uses hot conductive ionized gas (a plasma) as the moving conductor. The mechanical dynamo, in contrast, uses the motion of mechanical devices to accomplish this.

Practical MHD generators have been developed for fossil fuels, but these were overtaken by less expensive combined cycles in which the exhaust of a gas turbine or molten carbonate fuel cell heats steam to power a steam turbine.

MHD dynamos are the complement of MHD accelerators, which have been applied to pump liquid metals, seawater and plasmas.

Natural MHD dynamos are an active area of research in plasma physics and are of great interest to the geophysics and astrophysics communities, since the magnetic fields of the earth and sun are produced by these natural dynamos.

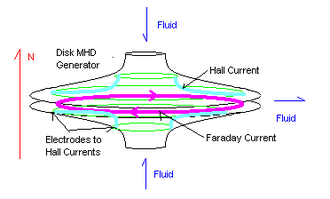

Disc generator[edit]

The third and, currently, the most efficient design is the Hall effect disc generator. This design currently holds the efficiency and energy density records for MHD generation. A disc generator has fluid flowing between the center of a disc, and a duct wrapped around the edge. (The ducts are not shown.) The magnetic excitation field is made by a pair of circular Helmholtz coils above and below the disk. (The coils are not shown.)

The Faraday currents flow in a perfect dead short around the periphery of the disk.

The Hall effect currents flow between ring electrodes near the center duct and ring electrodes near the periphery duct.

The wide flat gas flow reduced the distance, hence the resistance of the moving fluid. This increases efficiency.

Another significant advantage of this design is that the magnets are more efficient. First, they cause simple parallel field lines. Second, because the fluid is processed in a disk, the magnet can be closer to the fluid, and in this magnetic geometry, magnetic field strengths increase as the 7th power of distance. Finally, the generator is compact for its power, so the magnet is also smaller. The resulting magnet uses a much smaller percentage of the generated power.

Generator efficiency[edit]

The efficiency of the direct energy conversion in MHD power generation increases with the magnetic field strength and the plasma conductivity, which depends directly on the plasma temperature, and more precisely on the electron temperature. As very hot plasmas can only be used in pulsed MHD generators (for example using shock tubes) due to the fast thermal material erosion, it was envisaged to use nonthermal plasmas as working fluids in steady MHD generators, where only free electrons are heated a lot (10,000–20,000 kelvins) while the main gas (neutral atoms and ions) remains at a much lower temperature, typically 2500 kelvins. The goal was to preserve the materials of the generator (walls and electrodes) while improving the limited conductivity of such poor conductors to the same level as a plasma in thermodynamic equilibrium; i.e. completely heated to more than 10,000 kelvins, a temperature that no material could stand.[1][2][3][4]

But Evgeny Velikhov first discovered theoretically in 1962 and experimentally in 1963 that an ionization instability, later called the Velikhov instability or electrothermal instability, quickly arises in any MHD converter using magnetized nonthermal plasmas with hot electrons, when a critical Hall parameteris reached, hence depending on the degree of ionization and the magnetic field.[5][6][7] Such an instability greatly degrades the performance of nonequilibrium MHD generators. The prospects about this technology, which initially predicted awesome efficiencies, crippled MHD programs all over the world as no solution to mitigate the instability was found at that time.[8][9][10][11]

Also, MHDs work better with stronger magnetic fields. The most successful magnets have been superconducting, and very close to the channel. A major difficulty was refrigerating these magnets while insulating them from the channel. The problem is worse because the magnets work better when they are closer to the channel. There are also severe risks of damage to the hot, brittle ceramics from differential thermal cracking. The magnets are usually near absolute zero, while the channel is several thousand degrees.

A magnetohydrodynamic generator might also be the first stage of a gas-cooled nuclear reactor.[12]

Toxic byproducts[edit]

MHD reduces overall production of hazardous fossil fuel wastes because it increases plant efficiency. In MHD coal plants, the patented commercial "Econoseed" process developed by the U.S. (see below) recycles potassium ionization seed from the fly ash captured by the stack-gas scrubber. However, this equipment is an additional expense. If molten metal is the armature fluid of an MHD generator, care must be taken with the coolant of the electromagnetics and channel. The alkali metals commonly used as MHD fluids react violently with water. Also, the chemical byproducts of heated, electrified alkali metals and channel ceramics may be poisonous and environmentally persistent.

History[edit]

The first practical MHD power research was funded in 1938 in the U.S. by Westinghouse in its Pittsburgh, Pennsylvania laboratories, headed by Hungarian Bela Karlovitz. The initial patent on MHD is by B. Karlovitz, U.S. Patent No. 2,210,918, "Process for the Conversion of Energy", August 13, 1940.

Former Yugoslavia development[edit]

Over more than a ten-year span, engineers in former Yugoslavian Institute of Thermal and Nuclear Technology (ITEN), Energoinvest Co., Sarajevo, had built the first experimental Magneto-Hydrodynamic facility power generator in 1989. It was here it was first patented.[16][17]

U.S. development[edit]

In the 1980s, the U.S. Department of Energy began a vigorous multiyear program, culminating in a 1992 50 MW demonstration coal combustor at the Component Development and Integration Facility (CDIF) in Butte, Montana. This program also had significant work at the Coal-Fired-In-Flow-Facility (CFIFF) at University of Tennessee Space Institute.

This program combined four parts:

- An integrated MHD topping cycle, with channel, electrodes and current control units developed by AVCO, later known as Textron Defence of Boston. This system was a Hall effect duct generator heated by pulverized coal, with a potassium ionisation seed. AVCO had developed the famous Mk. V generator, and had significant experience.

- An integrated bottoming cycle, developed at the CDIF.

- A facility to regenerate the ionization seed was developed by TRW. Potassium carbonate is separated from the sulphate in the fly ash from the scrubbers. The carbonate is removed, to regain the potassium.

- A method to integrate MHD into preexisting coal plants. The Department of Energy commissioned two studies. Westinghouse Electric performed a study based on the Scholtz Plant of Gulf Power in Sneads, Florida. The MHD Development Corporation also produced a study based on the J.E. Corrette Plant of the Montana Power Company of Billings, Montana.

Initial prototypes at the CDIF were operated for short durations, with various coals: Montana Rosebud, and a high-sulphur corrosive coal, Illinois No. 6. A great deal of engineering, chemistry and material science was completed. After final components were developed, operational testing completed with 4,000 hours of continuous operation, 2,000 on Montana Rosebud, 2,000 on Illinois No. 6. The testing ended in 1993.[citation needed]

Japanese development[edit]

The Japanese program in the late 1980s concentrated on closed-cycle MHD. The belief was that it would have higher efficiencies, and smaller equipment, especially in the clean, small, economical plant capacities near 100 megawatts (electrical) which are suited to Japanese conditions. Open-cycle coal-powered plants are generally thought to become economical above 200 megawatts.

The first major series of experiments was FUJI-1, a blow-down system powered from a shock tube at the Tokyo Institute of Technology. These experiments extracted up to 30.2% of enthalpy, and achieved power densities near 100 megawatts per cubic meter. This facility was funded by Tokyo Electric Power, other Japanese utilities, and the Department of Education. Some authorities believe this system was a disc generator with a helium and argon carrier gas and potassium ionization seed.

In 1994, there were detailed plans for FUJI-2, a 5 MWe continuous closed-cycle facility, powered by natural gas, to be built using the experience of FUJI-1. The basic MHD design was to be a system with inert gases using a disk generator. The aim was an enthalpy extraction of 30% and an MHD thermal efficiency of 60%. FUJI-2 was to be followed by a retrofit to a 300 MWe natural gas plant.

Australian development[edit]

In 1986, Professor Hugo Karl Messerle at The University of Sydney researched coal-fueled MHD. This resulted in a 28 MWe topping facility that was operated outside Sydney. Messerle also wrote one of the most recent reference works (see below), as part of a UNESCO education program.

A detailed obituary for Hugo is located on the Australian Academy of Technological Sciences and Engineering (ATSE) website.[18]

Italian development[edit]

The Italian program began in 1989 with a budget of about 20 million $US, and had three main development areas:

- MHD Modelling.

- Superconducting magnet development. The goal in 1994 was a prototype 2 m long, storing 66 MJ, for an MHD demonstration 8 m long. The field was to be 5 teslas, with a taper of 0.15 T/m. The geometry was to resemble a saddle shape, with cylindrical and rectangular windings of niobium-titanium copper.

- Retrofits to natural gas powerplants. One was to be at the Enichem-Anic factor in Ravenna. In this plant, the combustion gases from the MHD would pass to the boiler. The other was a 230 MW (thermal) installation for a power station in Brindisi, that would pass steam to the main power plant.

Chinese development[edit]

A joint U.S.-China national programme ended in 1992 by retrofitting the coal-fired No. 3 plant in Asbach.[citation needed] A further eleven-year program was approved in March 1994. This established centres of research in:

- The Institute of Electrical Engineering in the Chinese Academy of Sciences, Beijing, concerned with MHD generator design.

- The Shanghai Power Research Institute, concerned with overall system and superconducting magnet research.

- The Thermoenergy Research Engineering Institute at the Nanjing's Southeast University, concerned with later developments.

The 1994 study proposed a 10 W (electrical, 108 MW thermal) generator with the MHD and bottoming cycle plants connected by steam piping, so either could operate independently.

Russian developments[edit]

In 1971 the natural-gas fired U-25 plant was completed near Moscow, with a designed capacity of 25 megawatts. By 1974 it delivered 6 megawatts of power.[19] By 1994, Russia had developed and operated the coal-operated facility U-25, at the High-Temperature Institute of the Russian Academy of Science in Moscow. U-25's bottoming plant was actually operated under contract with the Moscow utility, and fed power into Moscow's grid. There was substantial interest in Russia in developing a coal-powered disc generator. In 1986 the first industrial power plant with MHD generator was built, but in 1989 the project was cancelled before MHD launch and this power plant later joined to Ryazan Power Station as a 7th unit with ordinary construction.

https://en.wikipedia.org/wiki/Magnetohydrodynamic_generator

No comments:

Post a Comment